Carbon nano tube/polyaniline/polysulfone composite ultra-filtration membrane and preparing method thereof

A technology of carbon nanotubes and polyaniline, which is applied in the field of preparation of modified ultrafiltration membranes, can solve the problems of poor pollution resistance, poor charge responsiveness, and poor hydrophilicity of polysulfone membranes, and achieve simple equipment, convenient operation, and optimized The effect of separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

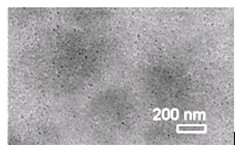

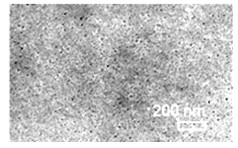

Image

Examples

Embodiment 1

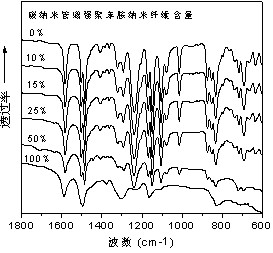

[0082] A preparation method of a pure polysulfone ultrafiltration membrane (that is, the carbon nanotube-reinforced polyaniline nanofiber content is 0%), specifically comprising the following steps:

[0083] (1) Preparation of casting solution

[0084] Weigh 1.5g polysulfone and add to 8.5g N - In methylpyrrolidone, stir magnetically for two days at 50° C. to form a light yellow homogeneous polysulfone solution with a concentration of 15%, which is the casting solution, and set aside;

[0085] (2) Coating film

[0086] With the aid of water-resistant adhesive tape, the polyester non-woven fabric was spread very smoothly on the glass plate, and the Doctor Blade adjustable film applicator was used to coat the film, and the thickness of the film was controlled to 152 μm; the polysulfone solution after degassing was placed in a straight line Apply it evenly on the polyester non-woven fabric horizontally, and then use a Doctor Blade type film applicator to apply...

Embodiment 2

[0092] A method for preparing a carbon nanotube / polyaniline / polysulfone composite ultrafiltration membrane, wherein the carbon nanotube-reinforced polyaniline nanofiber and polysulfone are calculated by mass percentage, that is, the carbon nanotube-reinforced polyaniline nanofiber: polysulfone 10%: 90%, that is, the carbon nanotube-reinforced polyaniline nanofiber content used is 10%, and its specific preparation steps are as follows:

[0093] (1) Preparation of casting solution

[0094] Weigh 1.35g polysulfone and add 7.15g N -Methylpyrrolidone, at 50 o Dissolving under C obtains polysulfone solution;

[0095] Weigh 0.15g carbon nanotube reinforced polyaniline nanofiber and add 1.35g N -Methylpyrrolidone at 50 o Ultrasonic dispersion at C for 6 hours to obtain a carbon nanotube-reinforced polyaniline nanofiber dispersion;

[0096] Then the above polysulfone solution and carbon nanotube reinforced polyaniline nanofiber dispersion were mixed at 50 o C under magn...

Embodiment 3

[0104] A method for preparing a carbon nanotube / polyaniline / polysulfone composite ultrafiltration membrane, wherein the carbon nanotube-reinforced polyaniline nanofiber and polysulfone are calculated by mass percentage, that is, the carbon nanotube-reinforced polyaniline nanofiber: polysulfone 15%: 85%, that is, the carbon nanotube-reinforced polyaniline nanofiber content used is 15%, and its specific preparation steps are as follows:

[0105] (1) Preparation of casting solution

[0106] Weigh 1.275g polysulfone and add 6.475g N -Methylpyrrolidone, at 50 o Dissolving under C obtains polysulfone solution;

[0107] Weigh 0.225g carbon nanotube reinforced polyaniline nanofiber and add 2.025g N -Methylpyrrolidone at 50 o Ultrasonic dispersion at C for 6 hours to obtain a carbon nanotube-reinforced polyaniline nanofiber dispersion;

[0108] Then the above polysulfone solution and carbon nanotube-reinforced polyaniline nanofiber dispersion were mixed uniformly at 50°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com