Preparation method of indium oxide-based gas-sensitive material with three-dimensional hollow multi-stage structure and application thereof

An indium oxide-based, gas-sensitive material technology, applied in the preparation and application of nanomaterials, can solve the problems of high raw material cost, complicated process, low formaldehyde sensitivity, etc., and achieve the effect of good sensitivity and short response recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 0.3mol / L InCl 3 2ml of the solution and 17ml of glycerol were placed in a polytetrafluoroethylene liner of a 50ml reactor, and stirred to form a uniform mixed solution. Then, 0.9 ml of ethylenediamine was added dropwise during stirring, and after stirring for 5 minutes, 0.66 g of surfactant cetyltrimethylammonium bromide (CTAB) was added, and stirred evenly again. Then seal the liner and put it into a stainless steel reaction kettle, heat it in an oven to 180°C for 12 hours; after the reaction is completed, take out the reaction kettle and cool it to room temperature under the air, and move the product into a centrifuge tube.

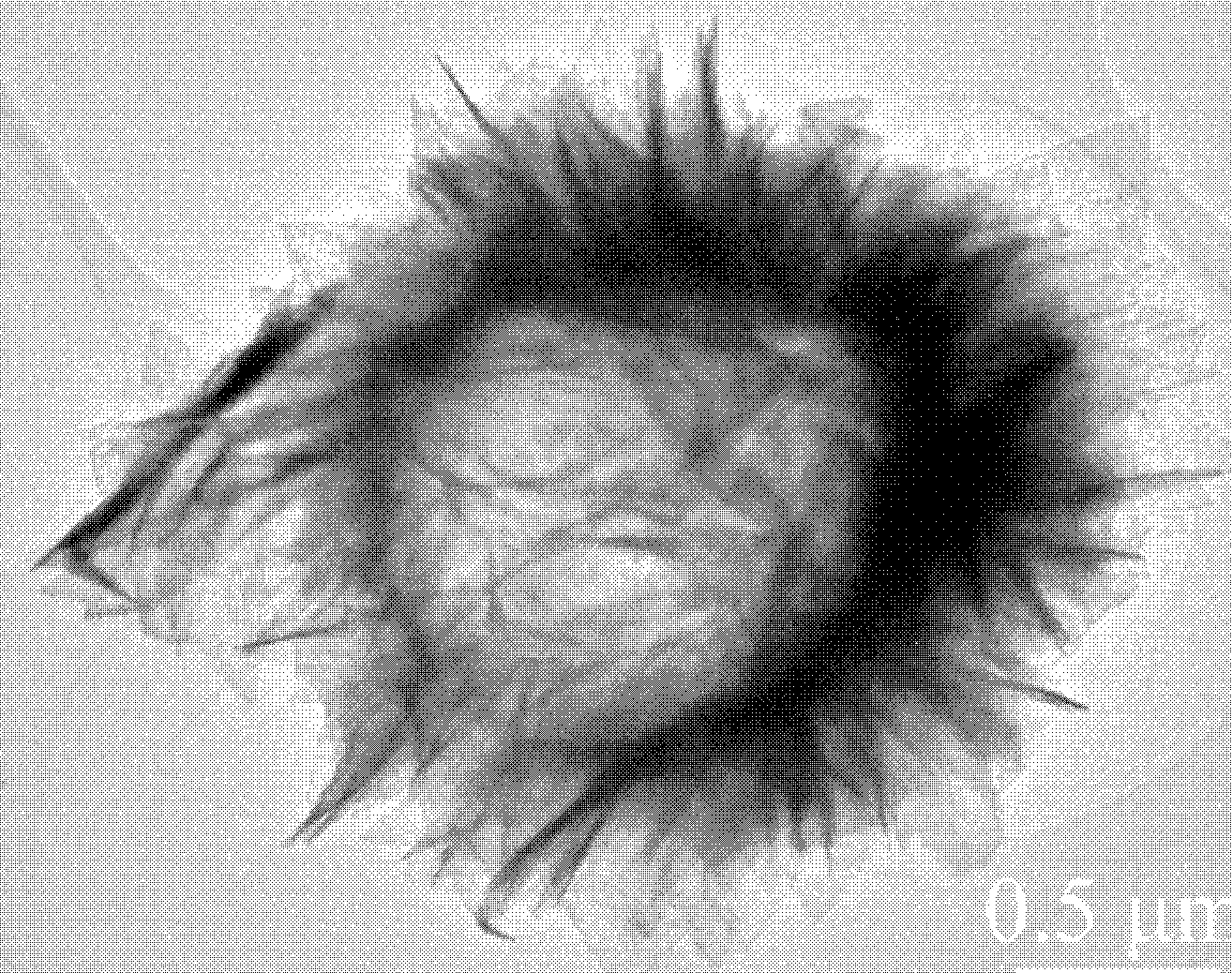

[0027] (2) The product was washed with deionized water and ethanol for 3 to 5 times. After centrifugation, the precipitate was transferred to a petri dish and dried in an oven at 50°C for 30 minutes to obtain a white three-dimensional flower-like hollow multi-level structure. indium oxide precursor.

[0028] (3) Put the indium oxide pr...

Embodiment 2

[0031] This example mainly investigates the effects of indium ion concentration, reaction time, reaction temperature and the amount of ethylenediamine added on the morphology of the obtained indium oxide during the preparation process of the multi-level structure of indium oxide. The specific experimental process is the same as in Example 1, the main difference is to change the concentration of indium ions, the reaction time, the reaction temperature and the amount of ethylenediamine added dropwise. The specific experimental parameters are shown in Table 1. It can be seen from the experimental results that the indium ion concentration and the reaction temperature have little effect on the sample morphology, but the reaction time is long and the amount of ethylenediamine added is large, and the sample morphology tends to form a three-dimensional flower-like hollow multi-level structure.

Embodiment 3

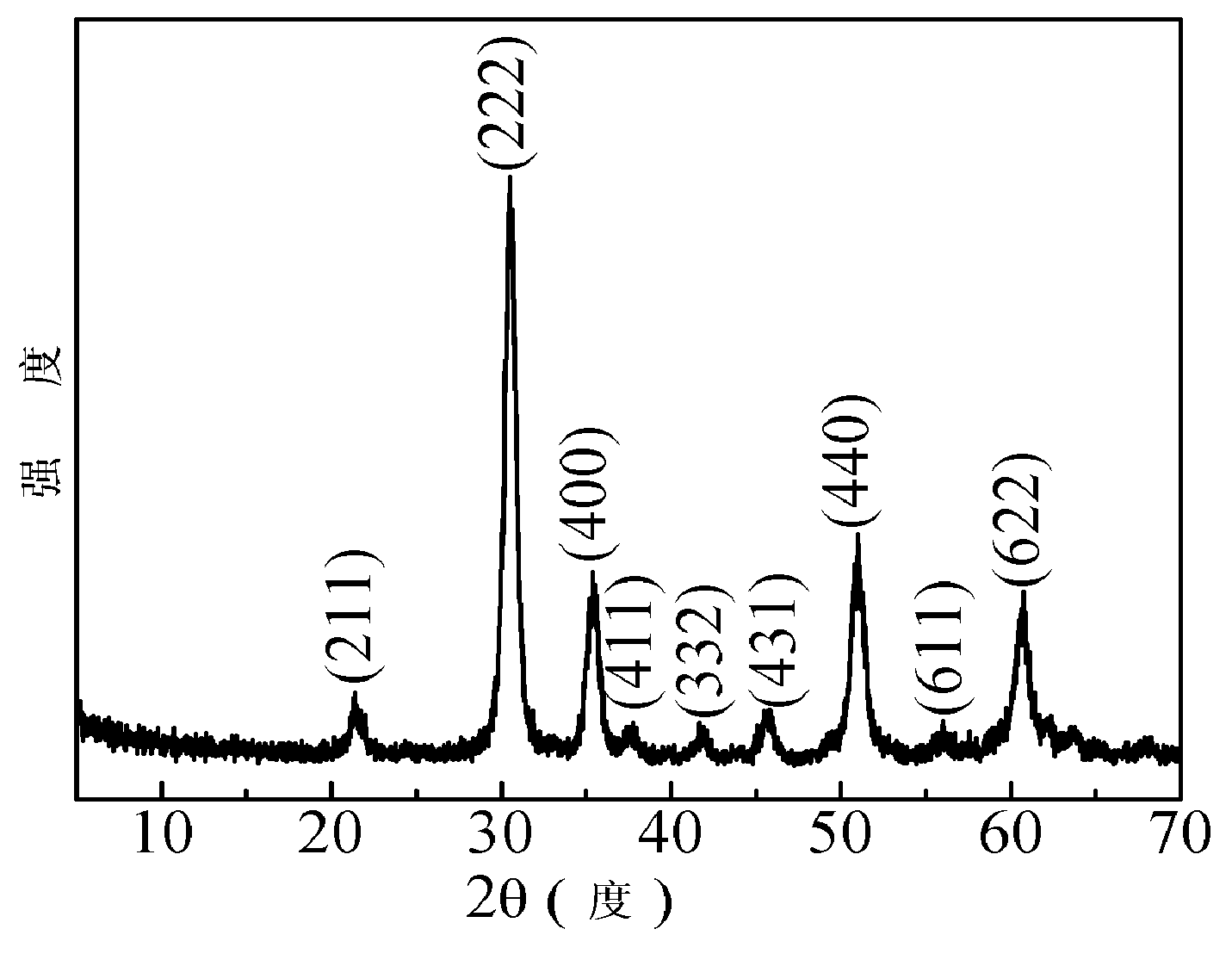

[0033] This embodiment mainly investigates the influence of the calcination temperature and calcination time on the composition of the obtained indium oxide sample during the preparation process of the multi-level structure of indium oxide. The specific experimental process is the same as step (3) of Example 1. The main difference is that the sintering temperature and calcination time are different. The specific experimental parameters are shown in Table 1. From the experimental results, it can be seen that the obtained product can be completely transformed at 260 ° C and above, and the calcination time is longer than 30 minutes. It is indium oxide, so the calcination temperature should be higher than 260°C, and the calcination time should be longer than 30min.

[0034] The relevant parameters of the examples of other preparation materials are listed in Table 1, please forgive me for not repeating them.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com