Surface modification method for polyvinylidene fluoride (PVDF) film or polyvinyl chloride (PVC) film

A polyvinylidene fluoride film and polyvinyl chloride film technology, which is applied in the field of surface modification of polyvinylidene fluoride film or polyvinyl chloride film, can solve the problem that the hydrophilic performance and anti-pollution performance cannot be greatly improved, and the experimental personnel Damage, complex experiments and other problems, to achieve the effects of good hydrophilicity and anti-pollution ability, less environmental pollution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

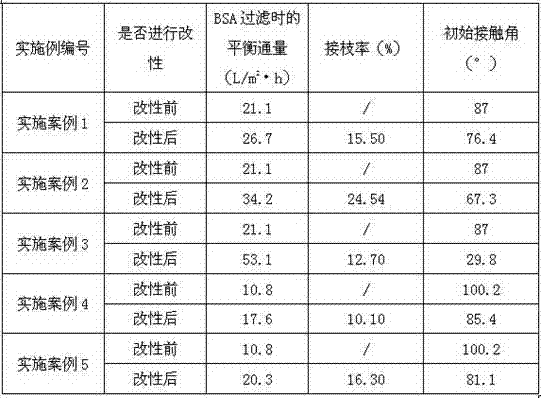

Embodiment 1

[0030] Surface modification method of polyvinylidene fluoride membrane

[0031] (1) Vacuum low temperature plasma treatment

[0032] The polyvinylidene fluoride film is subjected to vacuum low-temperature plasma treatment, wherein the low-temperature plasma medium is argon gas, the treatment power is 15W, the treatment time is 20min, and the reaction vacuum degree is 100Pa;

[0033] (2) Atom Transfer Radical Polymerization

[0034]Add 50ml of methanol and deionized water in a volume ratio of 1:1 and a clean magnetic stirring rotor into a 500ml three-necked flask, place the three-necked flask on the stirrer, turn on the stirring switch of the stirrer, and put the Pass pure nitrogen into the three-necked flask, keep blowing nitrogen for 30min, then add 2mmol of 2,2'-bipyridine, 7.5mmol of sulfobetaine methyl methacrylate into the three-necked flask, stir until completely dissolved, then add 1mmol of CuCl powder , stirred until fully dissolved, the solution was reddish-brown, t...

Embodiment 2

[0036] Surface modification method of polyvinylidene fluoride membrane

[0037] (1) Vacuum low temperature plasma treatment

[0038] Soak the polyvinylidene fluoride film in a 2% NaCl solution by mass for 30 minutes, then dry it, and then treat it with argon low-temperature plasma. The vacuum degree of the plasma reaction chamber is controlled at 12Pa, and the radio frequency power source is preheated. After 5 minutes, treat for 10 minutes under the condition of radio frequency power of 50W. After the treatment, place it in a vacuum chamber for 2 hours, then wash the membrane with pure water to remove residual NaCl on the surface, and dry it for later use;

[0039] (2) Atom Transfer Radical Polymerization

[0040] Add 100ml of methanol and deionized water in a volume ratio of 2:1 and a clean magnetic stirring rotor into a 500ml three-necked flask, place the three-necked flask on the stirrer, turn on the stirring switch of the stirrer, and put the Pass pure nitrogen into the ...

Embodiment 3

[0042] Surface modification method of polyvinylidene fluoride membrane

[0043] (1) Vacuum low temperature plasma treatment

[0044] Soak the polyvinylidene fluoride film in a 0.5% NaOH solution by mass for 60 minutes, then dry it in the air, and then treat it with chlorine gas low-temperature plasma. The vacuum degree of the plasma reaction chamber is controlled at 9 Pa, and the radio frequency power source is preheated for 10 minutes. Finally, treat it under the condition of radio frequency power of 40W for 10min, place it in a vacuum chamber for 2 hours after the treatment, then wash the membrane with pure water to remove the residual NaOH on the surface, and dry it for later use;

[0045] (2) Atom Transfer Radical Polymerization

[0046] Put methanol and deionized water in a volume ratio of 3:2 and a clean magnetic stirring rotor into a three-necked flask, place the three-necked flask on the stirrer, turn on the stirring switch of the stirrer, and pour high-purity argon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com