Method for coating micro-arc oxidation titanium implant with cefazolin sodium and chitosan composite drug membrane

A cefazolin sodium, micro-arc oxidation technology, applied in prosthesis, medical science, coating and other directions, can solve the problem of lack of anti-inflammatory effect, and achieve the prevention of wound infection, good sustained release effect, and accelerated wound healing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the method for loading cefazolin sodium and chitosan composite drug film on the micro-arc oxidation titanium implant of the present embodiment includes the following four steps:

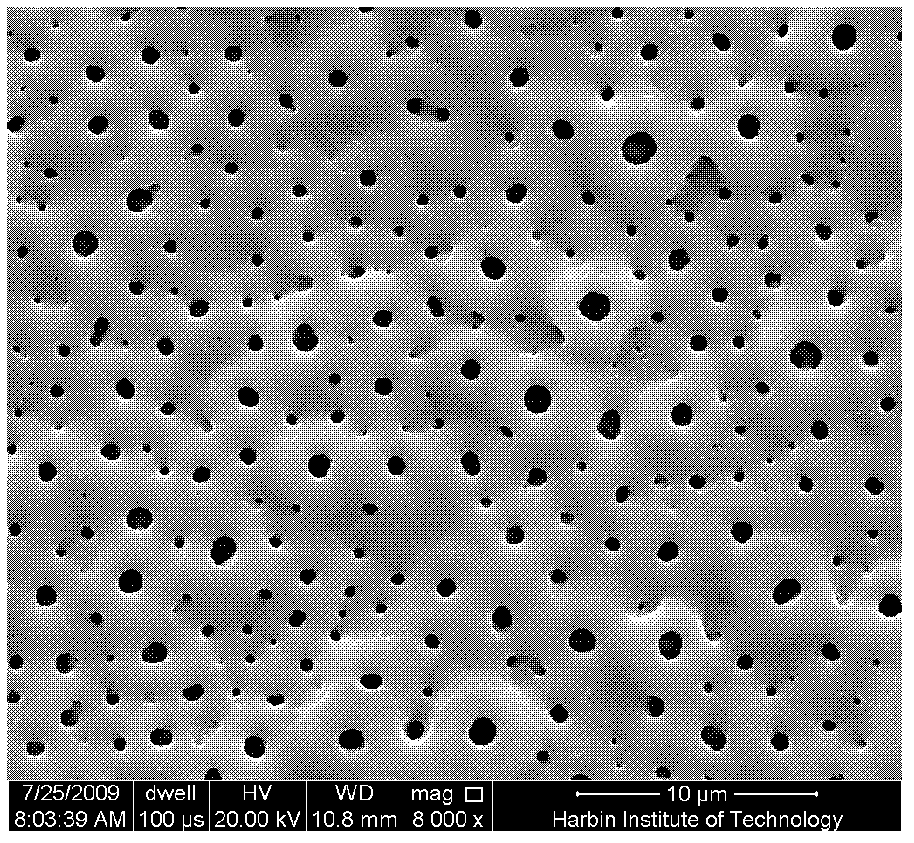

[0020] Step 1: Do micro-arc oxidation. Place the titanium implant in a stainless steel tank containing an alkaline electrolyte, use the titanium implant as the anode, and the stainless steel tank as the cathode; during the oxidation process, the temperature of the tank is controlled by the cooling system figure 1 and figure 2 ).

[0021] Step 2: cefazolin sodium injection is dissolved in deionized water, and a certain concentration of cefazolin sodium aqueous solution is prepared.

[0022] Step 3: Chitosan with a deacylation rate of more than 90% is added to the mixed solution of acetic acid and deionized water, and stirred until the chitosan is completely dissolved.

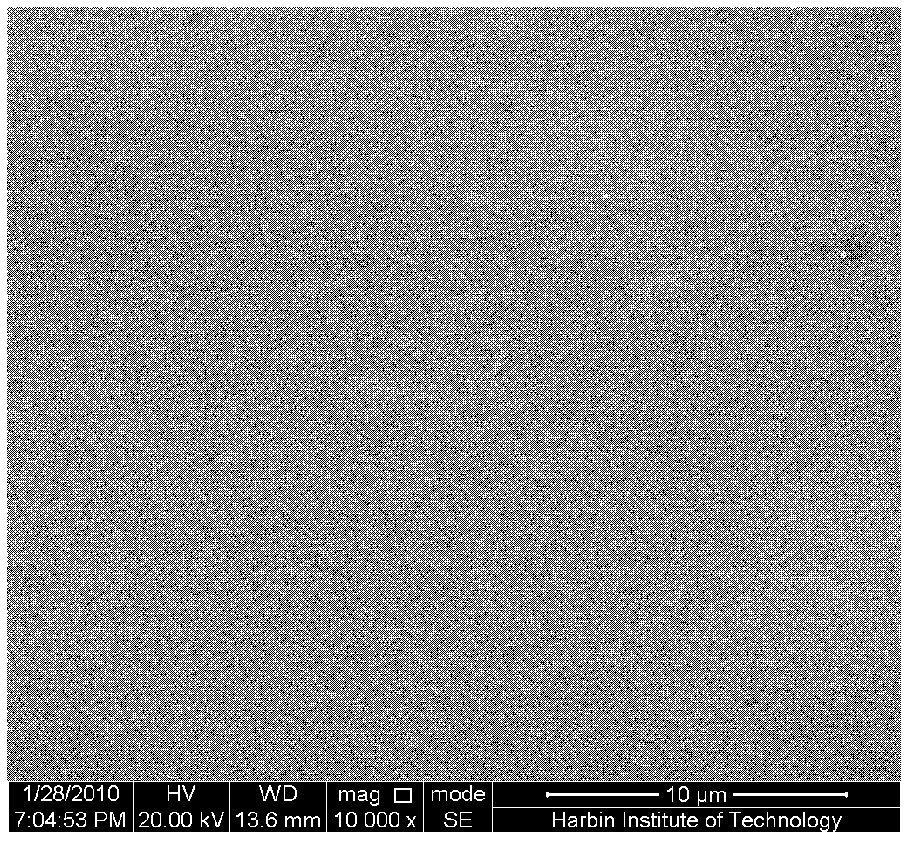

[0023] Step 4: drop the prepared cefazolin sodium aqueous solution into the chitosan aqueous soluti...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the energy of the micro-arc oxidation process is provided by an adjustable high-voltage and high-frequency bipolar pulse power supply, the pulse voltage is 200-500V, the frequency is 400-800Hz, The duty ratio is 4-20%, and the solution temperature is 0-50°C. Within the above selected electrical parameters of the micro-arc oxidation, the thickness of the coating can reach 3-10 microns after micro-arc oxidation for 5 minutes. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the method for loading cefazolin sodium drug film on the micro-arc oxidation titanium implant of the present embodiment includes the following six steps:

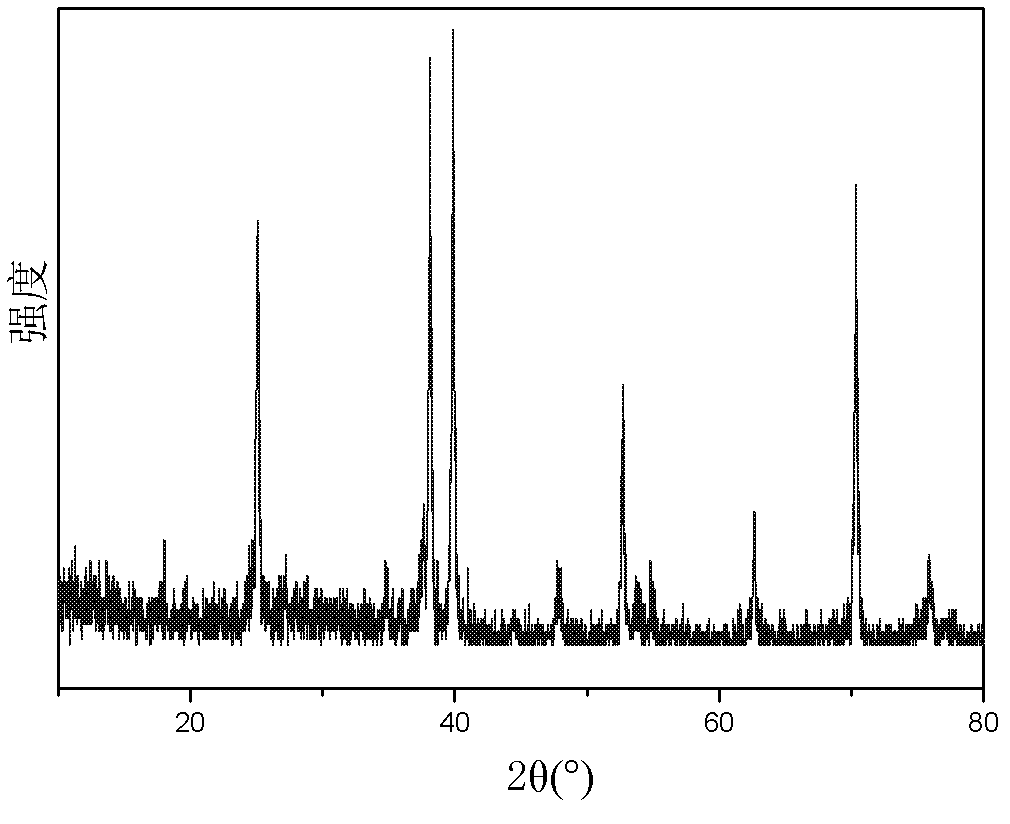

[0038] Step 1: Micro-arc oxidation: Put pure Ti in a solution containing EDTA-2Na, NaOH, Na 2 SiO 3 9H 2 O and Ca(CH3COO) 2 ·H 2 O (concentrations are set at 15 g / L, 20 g / L, 14.2 g / L and 8.8 g / L respectively) in a stainless steel tank made of deionized water as a solvent, the voltage of the power supply is 400V, The void ratio was 8%, the frequency was 600 Hz, and the oxidation time was 5 min, so that a micro-arc oxidation coating was formed on the surface of the pure titanium implant with a thickness of 5 microns.

[0039] EDS energy spectrum detection is carried out on the coating treated by the present invention, and there are trace active elements of Na, Si and Ca in the coating.

[0040] Step 2: Dissolve the cefazolin sodium injection in deionized water to prepare an aqueous solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com