Medical bionic transparent film implanting material, and preparation method and application of material

A technology for implanting materials and transparent films, which is applied in the fields of biomaterials and biomedicine, can solve the problems of ignoring transparency or loading therapeutic substances, and achieve the effects of promoting cell adhesion and growth, reducing scars, and enhancing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Dissolving type I collagen in an aqueous acetic acid solution with a mass concentration of 80% to prepare a type I collagen solution with a concentration of 85 mg / ml;

[0036] 2) Add chitosan substance at 4.0 mg / ml to the above-mentioned type I collagen solution, stir and dissolve, then add epidermal growth factor and stir to dissolve, the concentration of epidermal growth factor is 0.40 mg / ml;

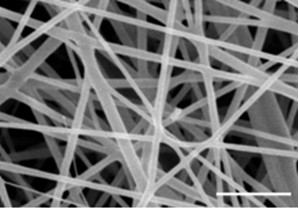

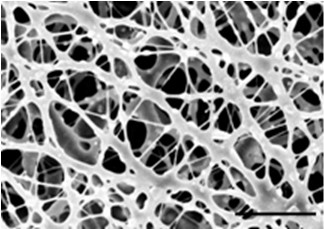

[0037] 3) Put the uniformly stirred mixed solution in step 2) into the propulsion system liquid reservoir of the electrospinning device; use the conductor plate as the receiving carrier, adjust the distance between the hollow metal nozzle at the front end of the propulsion system and the receiving carrier to be 12 cm, and the carrier Ground the wire, connect the hollow metal nozzle to a DC voltage of 15 kV, and push out the mixed solution in the propulsion system at a speed of 0.3 ml / hour. After electrospinning for 6 hours, the nanofibers accumulate on the receiving carrier a...

Embodiment 2

[0041] 1) dissolving type II collagen in an aqueous acetic acid solution with a mass concentration of 65% to prepare a type II collagen solution with a concentration of 70 mg / ml;

[0042] 2) Add an equal amount of chitosan and hyaluronic acid to the above-mentioned type II collagen solution at a total concentration of 3.0 mg / ml, stir to dissolve, then add chondroitin sulfate and stir to dissolve, the concentration of chondroitin sulfate is 0.20 mg / ml ml;

[0043] 3) Put the uniformly mixed solution in step 2) into the propulsion system liquid reservoir of the electrospinning device; use the conductor plate as the receiving carrier, adjust the distance between the hollow metal nozzle at the front end of the propulsion system and the receiving carrier to be 10 cm, and the carrier Ground the wire, connect the hollow metal nozzle to a 10 kV DC voltage, and push out the mixed solution in the propulsion system at a speed of 0.2 ml / hour. After 8 hours of electrospinning, the nanofibe...

Embodiment 3

[0047] The preparation method is the same as in Example 1, the difference is that: change the 0.40 mg / ml epidermal growth factor into 0.10 mg / ml nano-silver particles, change the DC voltage applied by the metal needle to 8 kV, adjust the hollow metal nozzle at the front end of the propeller and The distance between the fiber receiving carriers was changed to 10 cm, the mixed solution in the propeller was pushed out at a speed of 0.25 ml / hour, and electrospinning was carried out for 7 hours, and the ultrafine fibers loaded with nano-silver particles accumulated autonomously on the receiving carrier to form a For a porous film with a certain porosity and thickness, the porous film is chemically cross-linked with 0.15% glutaraldehyde solution for 4 hours, then rinsed repeatedly with a phosphate buffer solution with a pH of 7.0, and then dried to obtain a transparent film containing nano-silver Material. The transparency of the film is 83.6%, the thickness is 680 microns, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com