Method for manufacturing unsaturated polyester resin reinforced glass bead plate

A technology of reinforced glass and polyester fiber, applied in the direction of flat products, other household appliances, household appliances, etc., can solve the problems of lack of sound insulation, corrosion resistance, reduced mechanical strength of plates, limited use scope, etc., to reduce fire hazards, Good mechanical properties and a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The mass parts batching of each component of unsaturated polyester resin paste is as follows:

[0039] Table 1

[0040] Ortho-phthalic unsaturated polyester resin

90Kg

Low Shrinkage Additive Polyethylene

10Kg

1Kg

4Kg

BYK Dispersant

4Kg

tert-butyl peroxybenzoate

1Kg

Hollow glass microspheres (10μm)

150Kg

Aluminum hydroxide (5μm)

0Kg

1.2Kg

[0041]1) According to Table 1, pour 90Kg of o-phthalic unsaturated polyester resin and 10Kg of low-shrinkage additive polyethylene into the glue mixing tank and stir evenly, then add 1Kg of p-benzoquinone, 4Kg of zinc stearate, 4Kg of BYK dispersant, 1Kg of tert-butyl peroxybenzoate was stirred evenly, then added 150Kg of hollow glass microspheres (10 μm) through surface modification and stirred evenly, the present embodiment did not have aluminum hydroxide, all adopted hollow glass...

Embodiment 2

[0053] table 3

[0054] Ortho-phthalic unsaturated polyester resin

90Kg

Low Shrinkage Additive Polyethylene

10Kg

1Kg

4Kg

BYK Dispersant

3Kg

tert-butyl peroxybenzoate

1Kg

Hollow glass microspheres (10μm)

120Kg

Aluminum hydroxide (5μm)

30Kg

1.4Kg

[0055] 1) According to the above table 3, pour 90Kg of o-phthalic unsaturated polyester resin and 10Kg of low-shrinkage additive polyethylene into the glue mixing tank and stir evenly, then add 1Kg of o-benzoquinone, 4Kg of zinc stearate, and 3Kg of BYK dispersant , 1Kg of tert-butyl peroxybenzoate and stir evenly, then add 120Kg of hollow glass microspheres (10 μm) and 30Kg of aluminum hydroxide (5 μm) through surface modification and stir evenly, the particle diameter of hollow glass microspheres and aluminum hydroxide Ratio 2:1, mass ratio 4:1, finally add 1.4Kg of 35% magnesium ...

Embodiment 3

[0065] table 5

[0066] Ortho-phthalic unsaturated polyester resin

[0067] 1) According to the above table 5, pour 90Kg of o-phthalic unsaturated polyester resin and 10Kg of low-shrinkage additive polystyrene into the glue mixing tank and stir evenly, then add 1Kg of p-benzoquinone, 4Kg of zinc stearate, BYK dispersant 2Kg, 1Kg of tert-butylperoxy-2-ethylhexanoate and stir evenly, then add 100Kg of surface-modified hollow glass microspheres (10μm) and 50Kg of aluminum hydroxide (5μm) and stir evenly, the hollow glass microspheres The particle size ratio to aluminum hydroxide is 2:1, and the mass ratio is 2:1. Finally, 1.5 kg of 35% magnesium oxide paste is added and stirred evenly to obtain an unsaturated polyester resin paste.

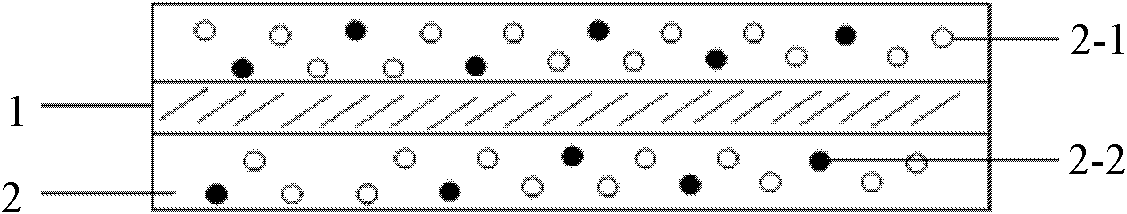

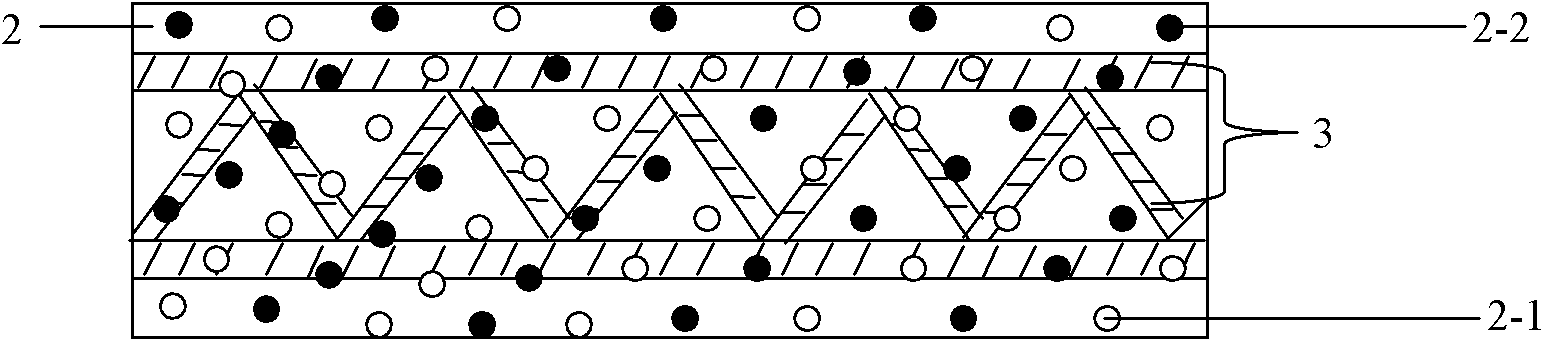

[0068] 2) The above resin paste is coated on the upper and lower sides of the glass fiber three-dimensional fabric respectively, and covered with a PET carrier film as a prepreg. The weight of glass fiber three-dimensional fabric is select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com