ZnO/enzyme biosensor and preparation method

A biosensor and bioenzyme technology, applied in the direction of material electrochemical variables, can solve the problems of complex process, restricted practicality, poor sensitivity, etc., and achieve the effect of simple preparation process, fast response speed, and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

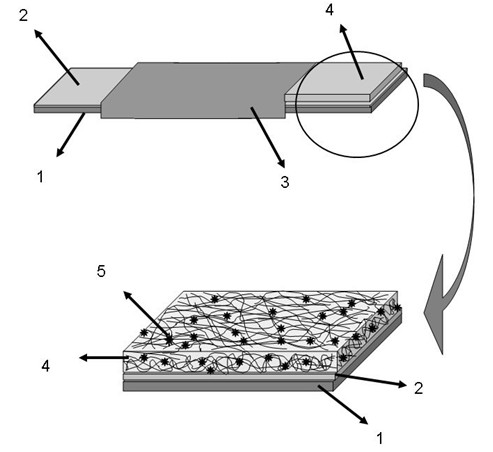

[0036] A ZnO / enzyme biosensor preparation method, comprising the steps of:

[0037] Step (1). Cut a silicon dioxide sheet or a glass sheet into a substrate 1 of e×f, and clean the substrate 1 ultrasonically for 30 minutes with anhydrous alcohol. 50 minutes, followed by ultrasonic cleaning with distilled water for 30 50 minutes, then put into the drying box for later use;

[0038] Said e and f are two adjacent sides of the substrate 1, and e is 1 mm 3mm, f is 10mm;

[0039] Step (2). The dried substrate 1 is plated with an electron beam evaporation or magnetron sputtering to form a substrate with a conductive thin film layer 2, and the thickness of the conductive thin film layer 2 is 50 200nm.

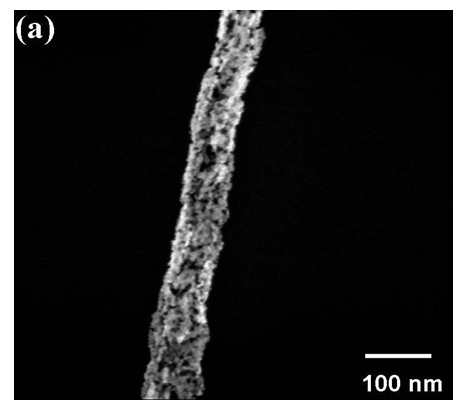

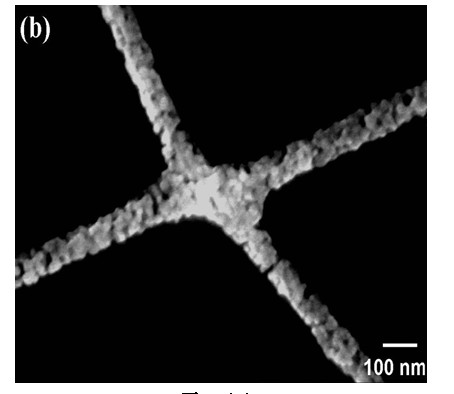

[0040] Step (3). The substrate is used for high-voltage electrospinning, and the exposed area at one end of the substrate is a Rectangle I of b, the rest is temporarily covered, high-voltage electrospinning parameters: zinc acetate is dissolved in 10-15 wt% polyvinyl alcohol a...

Embodiment 1

[0049] Step (1). Cut a silicon dioxide sheet or a glass sheet into a substrate 1 of 3 mm×10 mm, and clean the substrate 1 ultrasonically with anhydrous alcohol for 50 minutes, then ultrasonically clean it with distilled water for 50 minutes, and then put it into spare drying box;

[0050] Step (2). Electron beam evaporation or magnetron sputtering is used to coat the dried substrate 1 with a conductive film layer 2 to form a substrate. The thickness of the conductive film layer 2 is 200 nm.

[0051] Step (3). The substrate is used for high-voltage electrospinning, and the exposed area of one end of the substrate is 3 mm Rectangle I of 3mm, the rest is temporarily covered, high-voltage electrospinning parameters: dissolve zinc acetate in 12 wt% polyvinyl alcohol aqueous solution to form a mixed solution, wherein the mass ratio of polyvinyl alcohol to zinc acetate is 1; and the The mixed solution was heated and stirred at 40°C for 30 minutes. During the heating and stirring ...

Embodiment 2

[0056] Step (1). Cut a silicon dioxide sheet or a glass sheet into a substrate 1 of 2 mm×10 mm, and clean the substrate 1 ultrasonically with anhydrous alcohol for 40 minutes, then ultrasonically clean it with distilled water for 40 minutes, and then put it into spare drying box;

[0057] Step (2). Electron beam evaporation or magnetron sputtering is used to coat the dried substrate 1 with a conductive film layer 2 to form a substrate. The thickness of the conductive film layer 2 is 100 nm.

[0058] Step (3). The substrate is used for high-voltage electrospinning, and the exposed area of one end of the substrate is 2 mm Rectangle Ⅰ of 2mm, the rest is temporarily covered, high-voltage electrospinning parameters: dissolve zinc acetate in a 10 wt% polyvinyl alcohol aqueous solution to form a mixed solution, wherein the mass ratio of polyvinyl alcohol to zinc acetate is 0.8; and the The mixed solution was heated and stirred at 50°C for 20 minutes. During the heating and stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com