Wet etching method of Mn-Co-Ni-O thermosensitive thin film

A mn-co-ni-o, heat-sensitive film technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of etching failure and low etching efficiency, and reach the mesa side The eclipse ratio is small, the graphics quality is high, and the effect of ensuring the speed of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The concentration of iodide ion and hydrochloric acid was fixed, and the change of corrosion rate under different temperature conditions was investigated.

[0052] Concentrated hydrochloric acid with a mass fraction of 36%, deionized water, and potassium iodide were prepared in a ratio of 3ml:7ml:5g to prepare an etching solution, and etching experiments were carried out in water bath environments at 27°C and 32°C. The etching process is completed within 5 minutes after the etching solution is prepared, and the etching time is 1.5 minutes. Measure the step height with a step meter, and calculate the average etching rate:

[0053] Table 1.c (I - )=3mol L -1 , c(H + )=3mol L -1 Etching rate under different temperature conditions

[0054] temperature(℃)

Embodiment 2

[0056] The fixed concentration of hydrochloric acid is 2mol L -1 , The change of etching rate under different iodide ion concentration conditions.

[0057] Table 2.27°C, H + The concentration is 2mol L -1 different I - Etch rate at concentration

[0058]

Embodiment 3

[0060] Table 3 shows that the solution prepared according to Example 1 is etched after being placed for a specific period of time (2 minutes, 6 minutes, 11 minutes) under the condition of ordinary indoor sunlight and an unsealed etching solution, and the etching rate is obtained. value. Iodide ions in the etching solution are strongly reducing and will be oxidized by oxygen dissolved in the etching solution. This process is faster under light conditions, which affects the reaction rate, so the reaction should be carried out in a dark room.

[0061] Table 3.1-12 minutes of etching rate reduction

[0062]

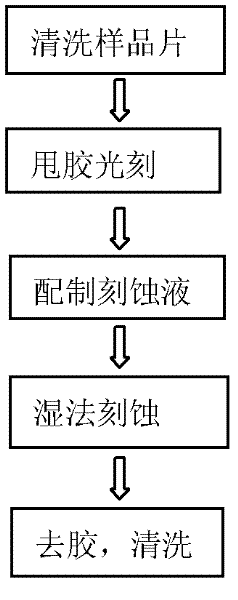

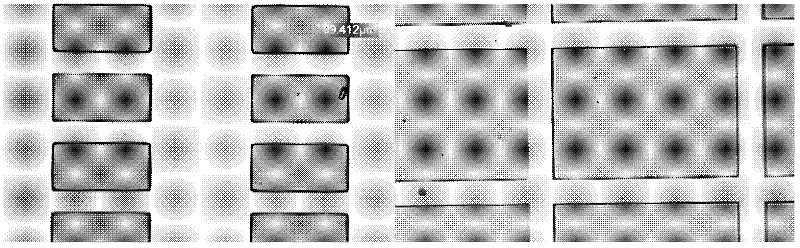

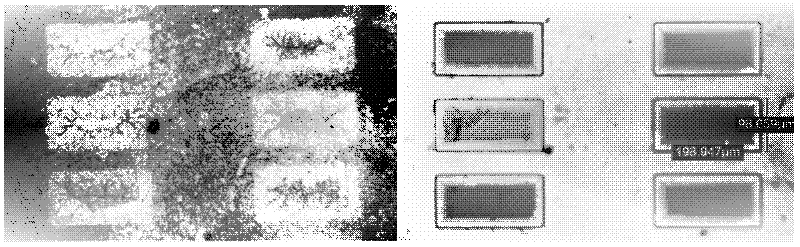

[0063] figure 1 A schematic flow chart of the specific implementation steps is given. Photoresist patterns were obtained using a microscope ( figure 2 ), the effect of etching solution on photoresist ( image 3 ) and wet etching to complete the final effect ( Figure 4 ).

[0064] figure 2 Two sizes of photoresist strips are shown (200 μm x 100 μm, 500 μm x 700 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com