Preparation method of polyaniline/carbon nano tube/nano-copper composite material

A technology of carbon nanotube composite and carbon nanotube, which is applied in the direction of electrolytic capacitors, capacitors, electrical components, etc., can solve the problems of low capacitance and low conductivity, achieve the effect of pure product, improve conductivity and prevent oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

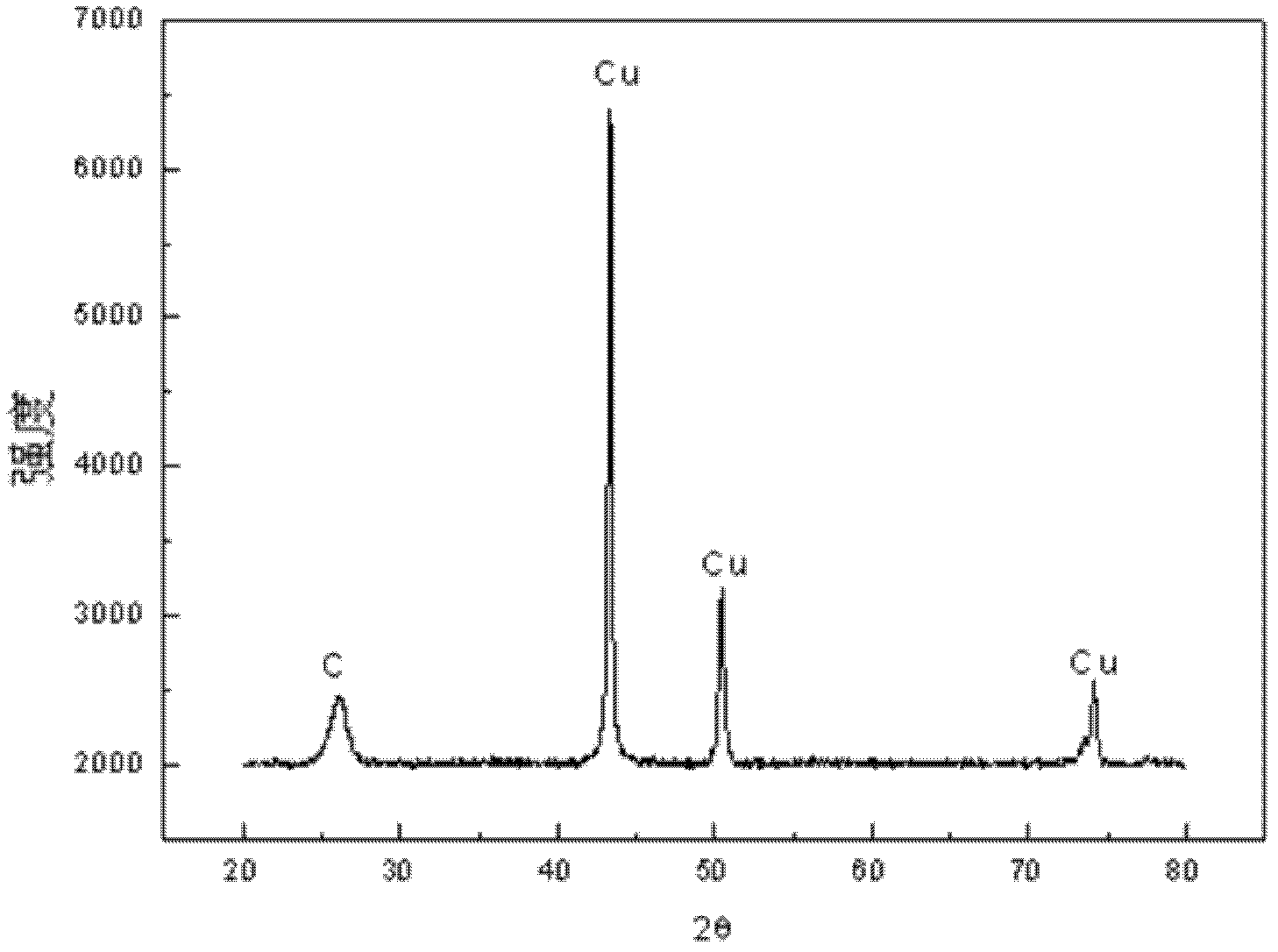

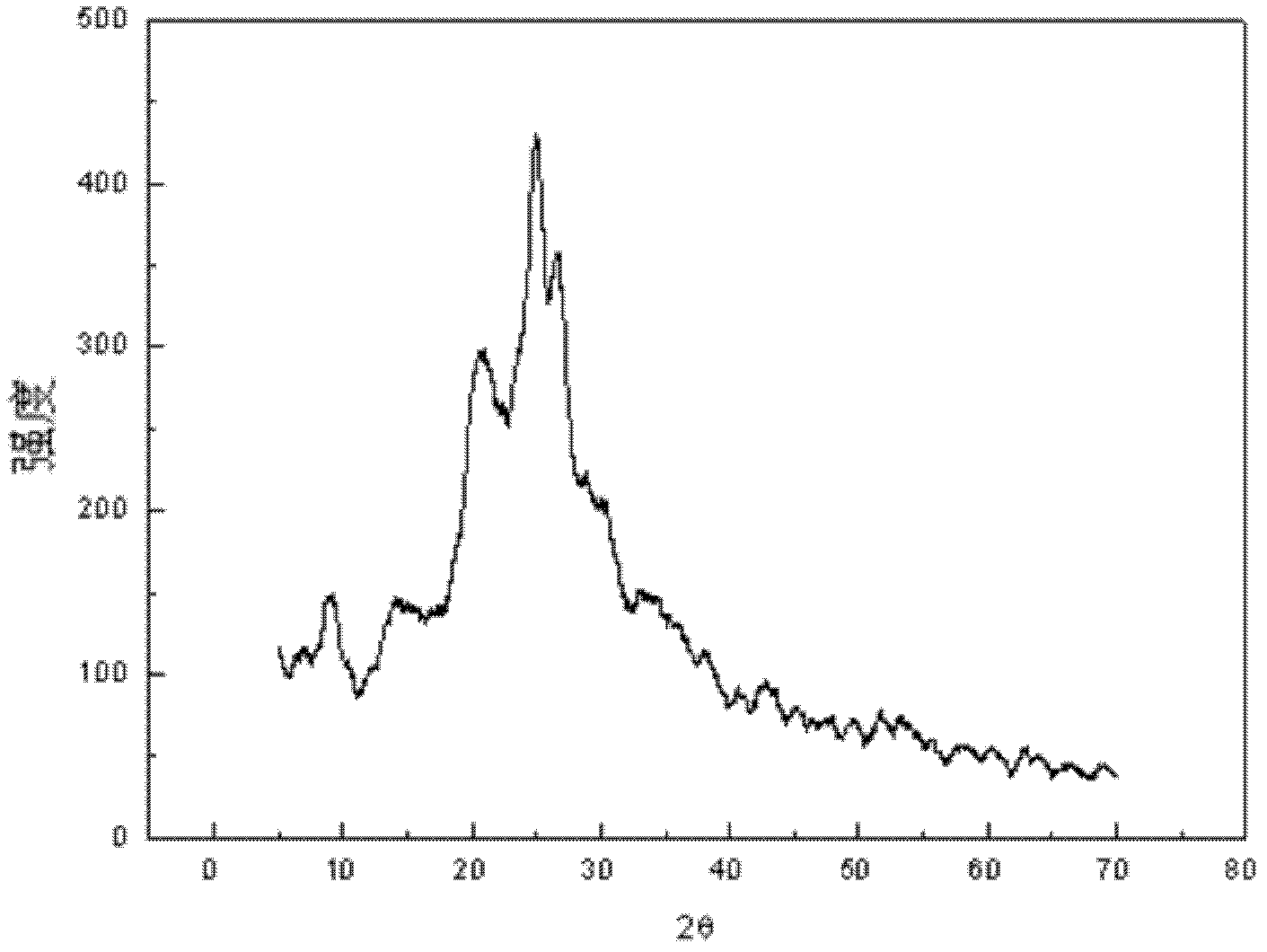

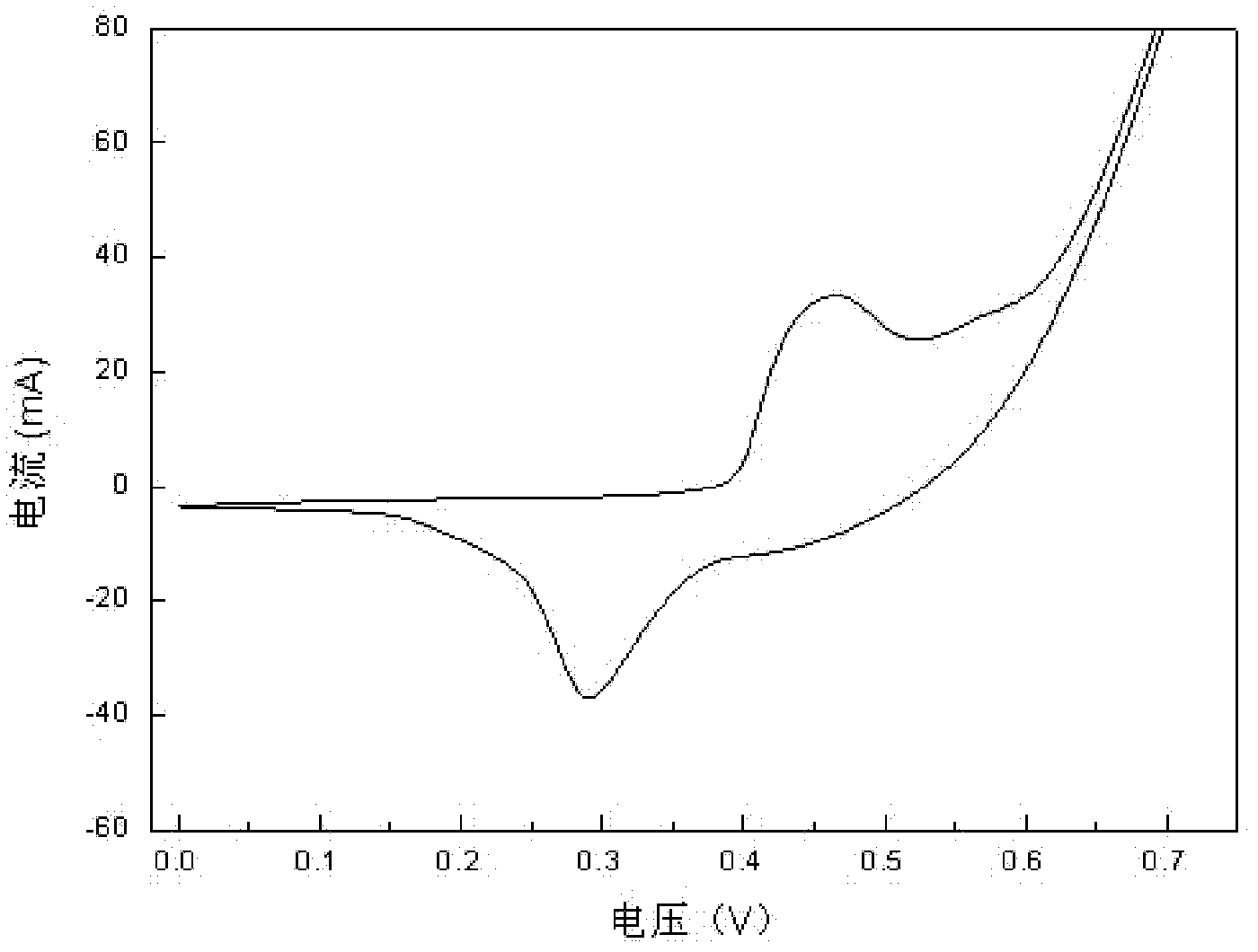

[0023] Specific embodiment one: the preparation method of a kind of polyaniline / carbon nanotube / nano-copper composite material of this embodiment is carried out according to the following steps:

[0024] 1. Acidification treatment of carbon nanotubes: mix concentrated sulfuric acid and concentrated nitric acid evenly at a volume ratio of 3:1 to obtain a mixed solution; add carbon nanotubes to the above mixed solution at a ratio of 1g:80mL according to the mass-volume ratio Put it into a three-necked bottle with a reflux cooling device, stir and mix evenly, then heat to 50°C-80°C, and reflux for 1-3h at a stirring speed of 200-500r / min, cool to room temperature, filter, and then remove the solid phase Wash until the pH is 7.0, then put it into a vacuum drying oven, and dry it for 12 to 48 hours at a temperature of 40°C to 60°C to obtain acidified carbon nanotubes;

[0025] Two, the preparation of nano-copper / carbon nanotube composite powder: the mass volume ratio of the acidifi...

specific Embodiment approach 2

[0035] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the vacuum degree of the suction filtration and washing described in step two and step three is 2×10 4 Pa. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment three: this embodiment is different from specific embodiments one to two in that: the dropping speed described in step three is 1 drop / 15 seconds. Others are the same as the specific embodiment 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com