Method for preparing nanometer metallic oxide by bulk metallic oxide

A nano-metal and bulk metal technology, applied in the direction of oxide/hydroxide preparation, zinc oxide/zinc hydroxide, chemical instruments and methods, etc., can solve the problems of complex production process and high production cost, and achieve air stability The effect of high stability, short synthesis time and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 The process of synthesizing nano cadmium oxide

[0038] Put 0.128g (1mmol) cadmium oxide powder, 1ml oleic acid and 5ml oleylamine into the three-necked bottle, then plug the two sides of the three-necked bottle with rubber stoppers, connect the middle port to the Schlenk system, and connect the thermocouple Insert it from one side of the three-neck bottle (such as the right side) under the liquid surface, stir and heat, and when heated to 180°C, the cadmium oxide is completely dissolved to obtain a clear solution. When continuing to heat to 260°C, the color of the transparent solution gradually turns yellow and turbid, that is, nano-cadmium oxide is formed, which is the starting point for the growth of nano-cadmium oxide.

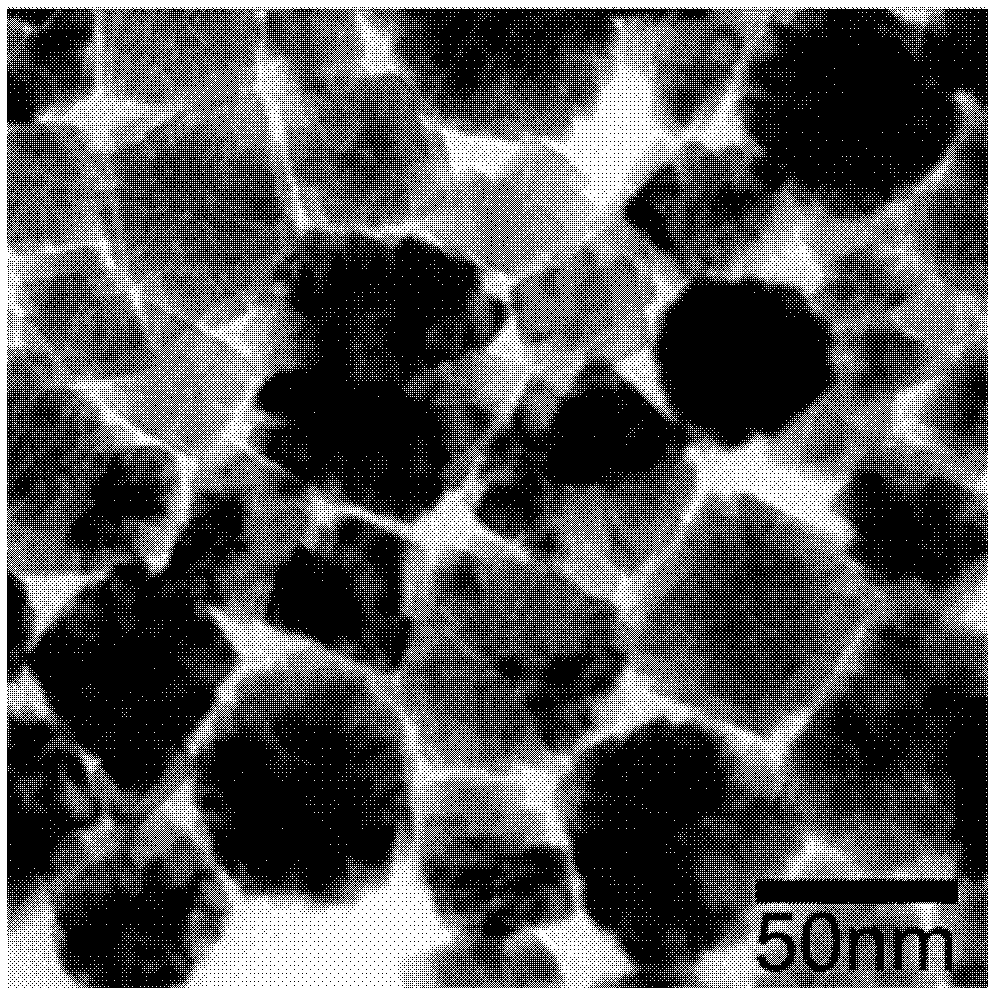

[0039] Samples were extracted for sample characterization at different growth times (1, 2, 10 minutes and longer). figure 1 It is a nano-cadmium oxide sample with a growth time of 1 minute, which is a nano-cluster, and the size of the ...

Embodiment 2

[0042] Embodiment 2 The process of synthesizing nano zinc oxide

[0043] The process of synthesizing nano zinc oxide is the same as the process of synthesizing cadmium oxide in Example 1, only need to replace 0.128g (1mmol) cadmium oxide powder with 0.081g (1mmol) zinc oxide powder. Zinc oxide dissolves completely when heated to 180°C. Continue heating, and when the temperature reaches 240°C, the color of the transparent solution gradually changes to light yellow and turbid, that is, nano-zinc oxide is formed.

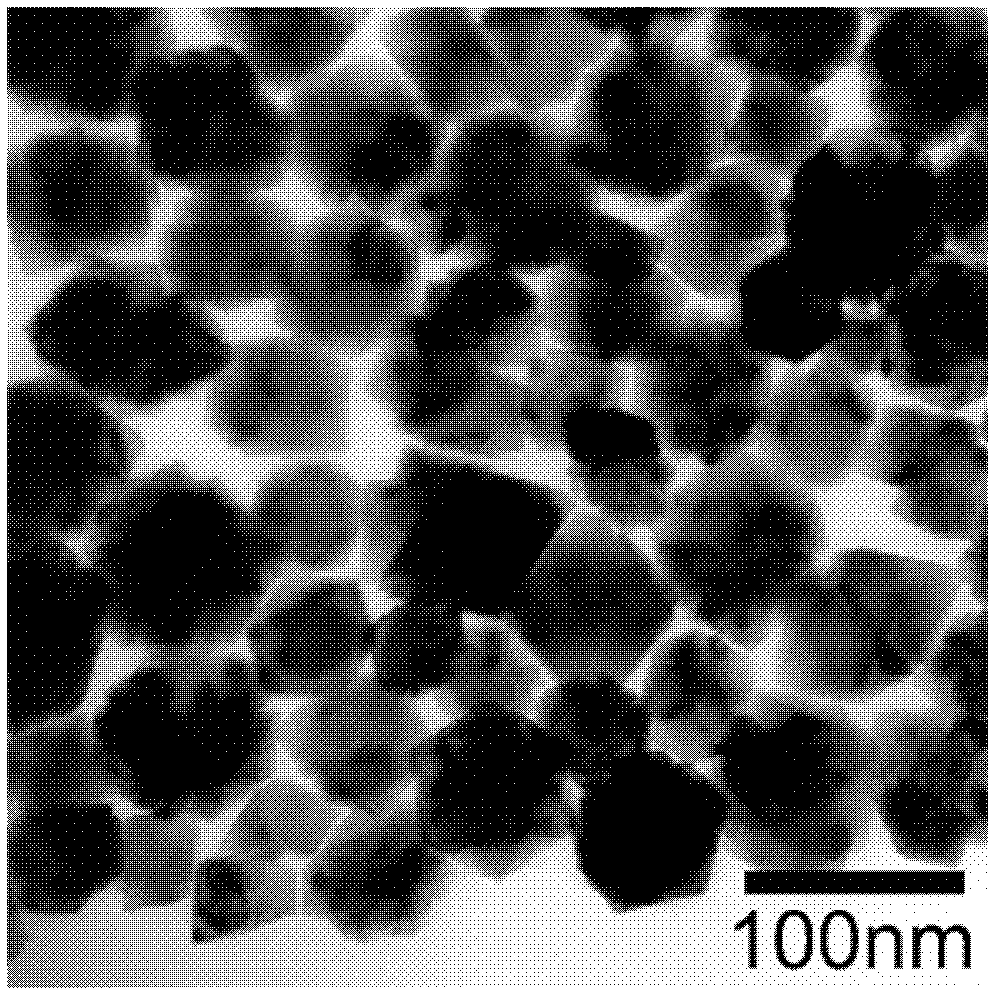

[0044] The transmission electron microscope pictures of nano-zinc oxide samples are as follows: Figure 9 , 10 as shown, Figure 9 is the morphology of the sample when reacted for 1 minute, Figure 10 is the sample morphology when reacted for 10 minutes, and the morphology and size of the two samples have little change. The X-ray diffraction pattern of nano-zinc oxide is as follows: Figure 11 As shown, it is a wurtzite hexagonal structure (JCPDS No.79-205), whic...

Embodiment 3

[0045] Embodiment 3 The process of synthesizing nano gallium oxide

[0046] Put 0.0469g (0.25mmol) of gallium oxide powder, 1ml of oleic acid and 5ml of oleylamine into a three-necked bottle, connect it to a Schlenk system, stir and heat. When heated to 240°C, the color of the solution gradually turns orange-red and turbid, that is, nano-gallium oxide is formed.

[0047] Figure 14 It is a transmission electron microscope picture of a nano-gallium oxide sample, which is a morphology similar to a porous structure. Figure 15 It is the X-ray diffraction pattern of the nano-gallium oxide sample, which completely corresponds to the standard card of gallium oxide (JCPDS No. 43-1012), and the structure is consistent with the structure of the reaction raw material bulk gallium oxide.

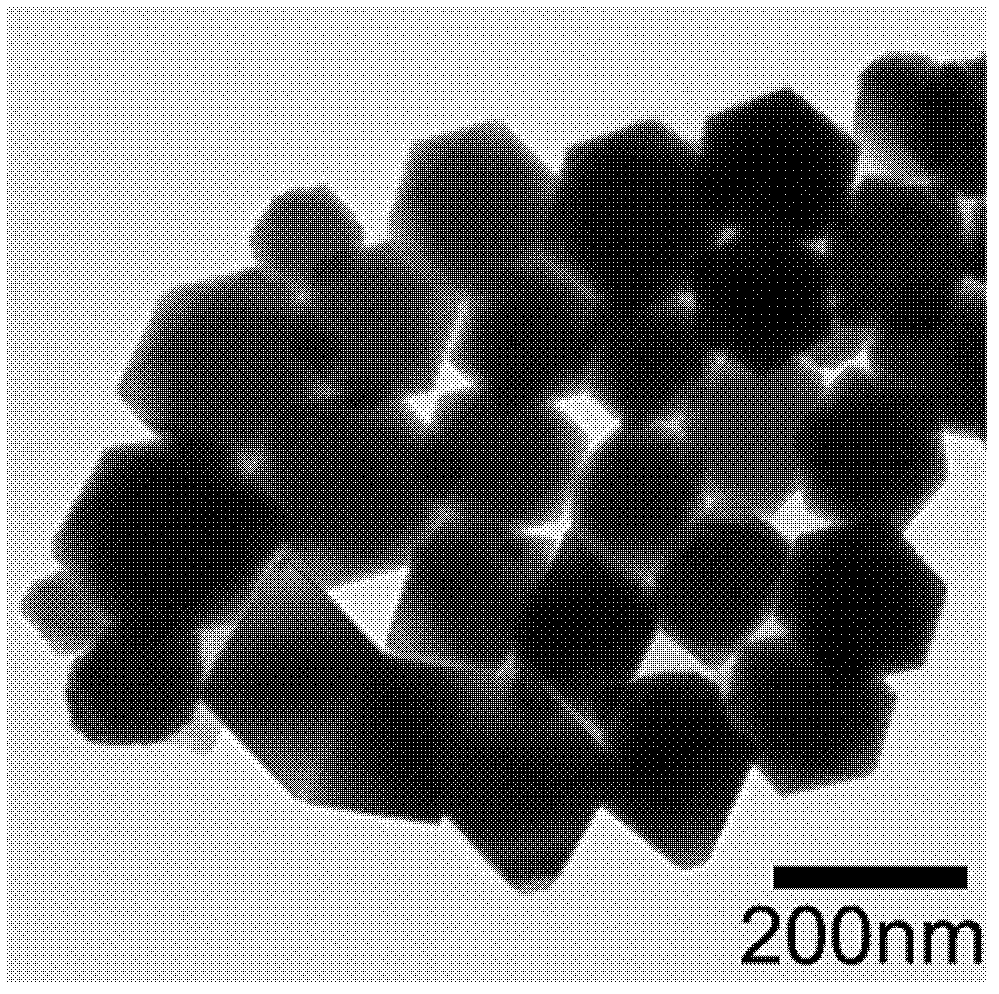

[0048] Figures 16-18 It is the scanning electron microscope picture of bulk cadmium oxide, zinc oxide and gallium oxide that this method adopts respectively, from Figures 16-18 It can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com