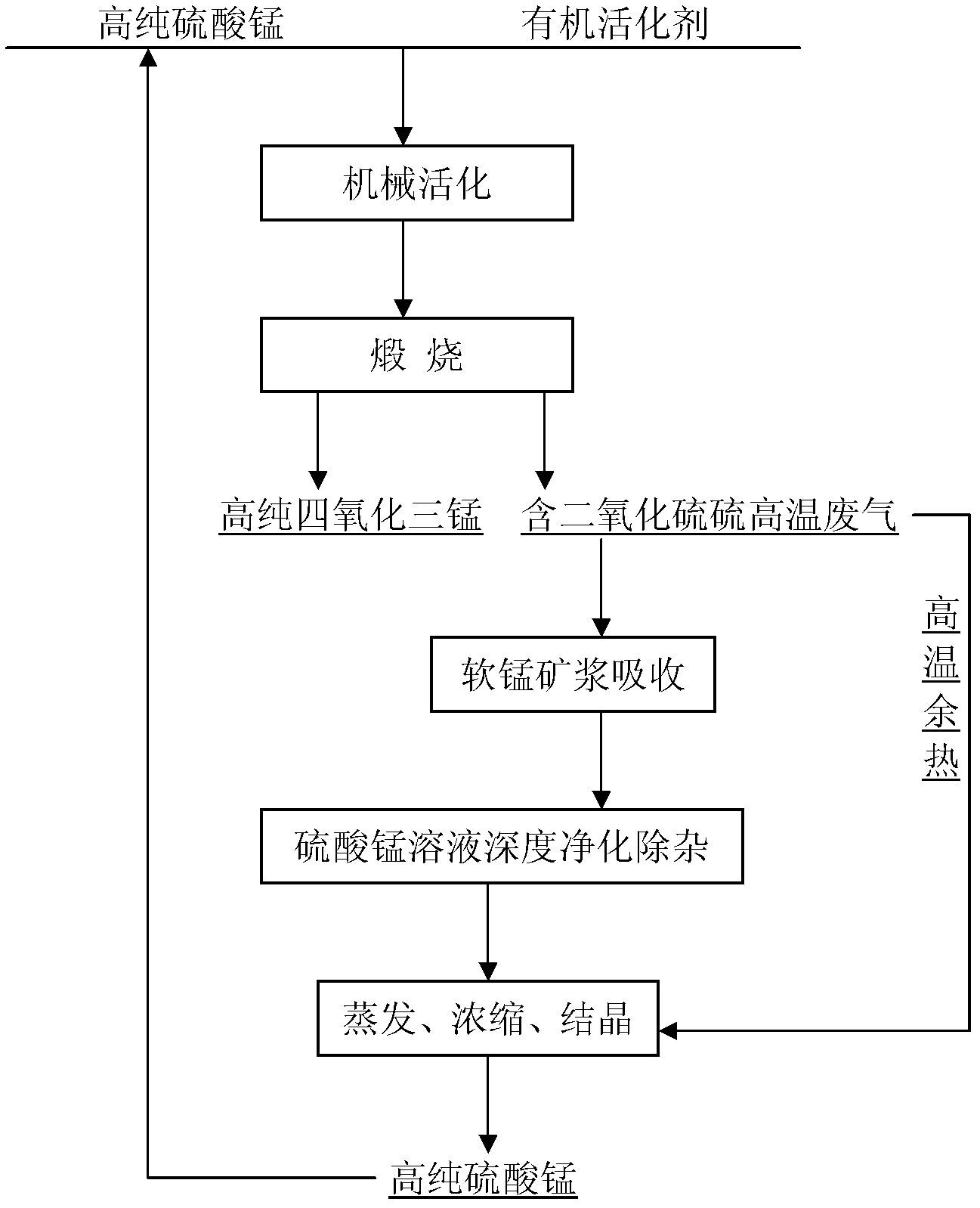

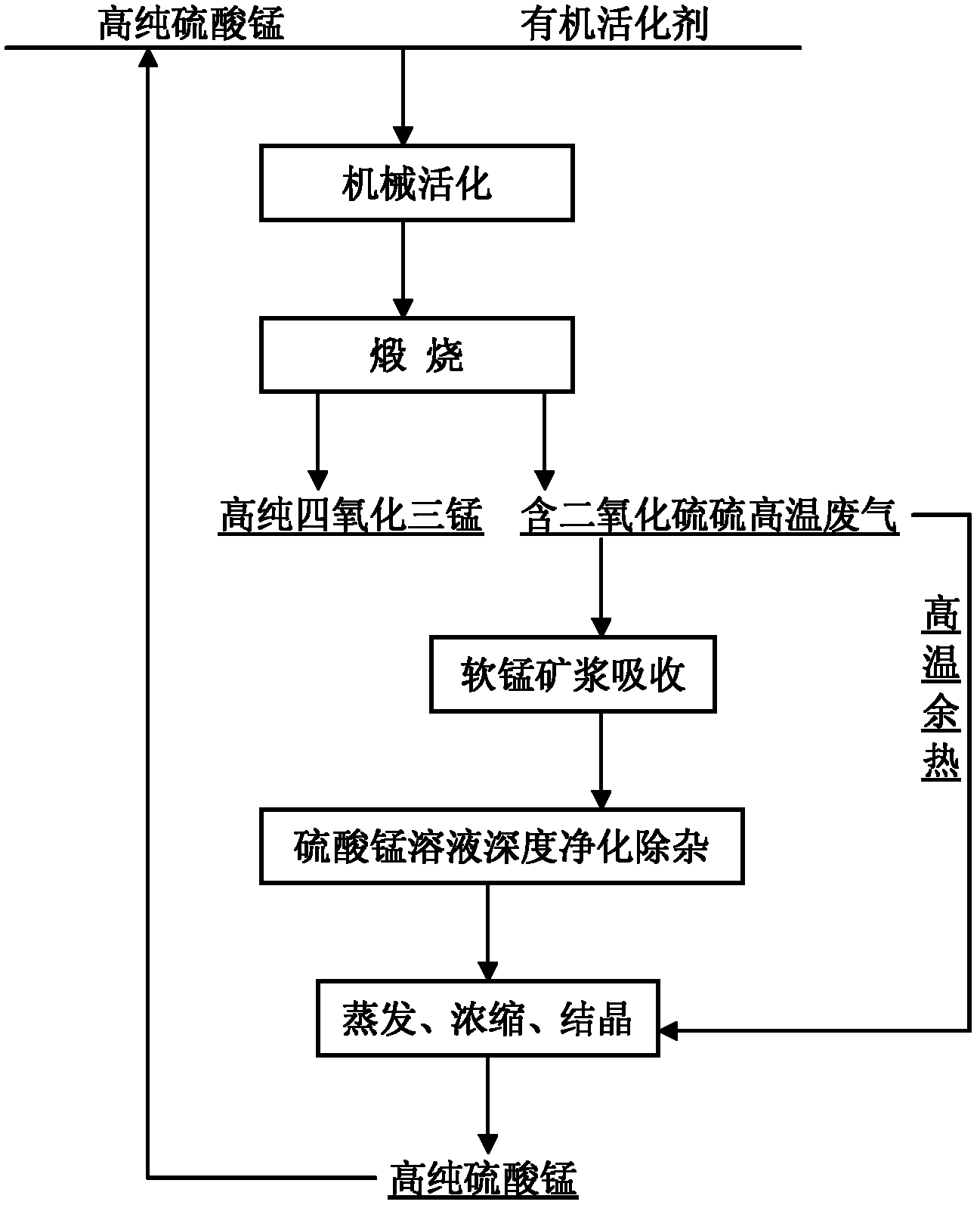

High-purity trimanganese tetroxide and preparation method of same

A high-purity technology of trimanganese tetraoxide, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of removal, unexplained, incomplete absorption, etc., and achieve the goal of improving specific surface area, avoiding secondary pollution, and reducing decomposition temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Add high-purity manganese sulfate meeting quality standards into acetone with 2% by weight as an organic activator, and then mix and activate in a ball mill for 3 hours. Send the mechanically activated raw materials into the calcination equipment, control the temperature at 900°C, and calcine in the air atmosphere for 3 hours. The amount of air introduced is based on the volume concentration of the sulfur dioxide gas that can be produced by the pyrolysis of manganese sulfate mixed with the introduced gas. 15% (V / V) is controlled to generate qualified manganese tetraoxide powder, and simultaneously the sulfur dioxide gas generated by calcination is drawn out and the Chinese patent 200510021926. 200910058061.2 A reactor suitable for leaching pyrolusite with sulfur dioxide gas, 200910058062.7 A method for preparing manganese sulfate solution by leaching pyrolusite with sulfur dioxide gas, 200910060313.5 Inhibiting dithionic acid in the process of leaching pyrolusite with sul...

Embodiment 2

[0030] Add high-purity manganese sulfate meeting the quality standard into glycerol with a mass of 4% as an organic activator, and then mix and activate in a mixer for 4 hours. Send the mechanically activated raw materials to the calcination equipment, control the temperature at 950°C, and calcine for 3.5 hours under a nitrogen atmosphere. The volume concentration is 10% (V / V) to control to generate qualified manganese tetraoxide powder, and simultaneously lead out the sulfur dioxide gas generated by calcination and use Chinese patent 200510021926. Method for desulfurizing exhaust gas with pH buffer as composite absorbent, 200910058061.2 Reactor suitable for leaching pyrolusite with sulfur dioxide gas, 200910058062.7 Method for preparing manganese sulfate solution by leaching pyrolusite with sulfur dioxide gas, 200910060313.5 Inhibiting continuous pyrolusite during leaching of pyrolusite with sulfur dioxide gas The method for manganese disulfate generation is to absorb and gen...

Embodiment 3

[0032] Add high-purity manganese sulfate meeting the quality standard into its mass percent acetaldehyde as an organic activator, and then seal and mix in a ball mill for activation for 2.5 hours. Send the mechanically activated raw materials into the calcination equipment, control the temperature at 1000°C, and calcine for 3.5 hours in an atmosphere of air and nitrogen mixed gas. The volume concentration after the mixed gas is controlled by 5% (V / V), and the manganese manganese tetraoxide powder that meets the requirements is generated, and the sulfur dioxide gas generated by calcination is simultaneously drawn out and the Chinese patent that the patent applicant of the present invention has been authorized is adopted. 200510021926.X Method for waste gas desulfurization using pyrolusite and pH buffer as composite absorbent, 200910058061.2 Reactor suitable for leaching pyrolusite with sulfur dioxide gas, 200910058062.7 Method for preparing manganese sulfate solution by leaching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com