Rare earth coupling agent, preparation method and application thereof in treatment of glass fiber reinforced polyformaldehyde composite material

A technology of rare earth coupling agent and composite material, which is applied in the field of preparation of rare earth coupling agent to treat glass fiber reinforced polyoxymethylene composite material, which can solve the problems of poor compatibility, weak combination, exposed fiber POM matrix interface, etc., and achieve enhanced Interfacial interaction, excellent weather resistance, and the effect of improving interfacial compatibility

- Summary

- Abstract

- Description

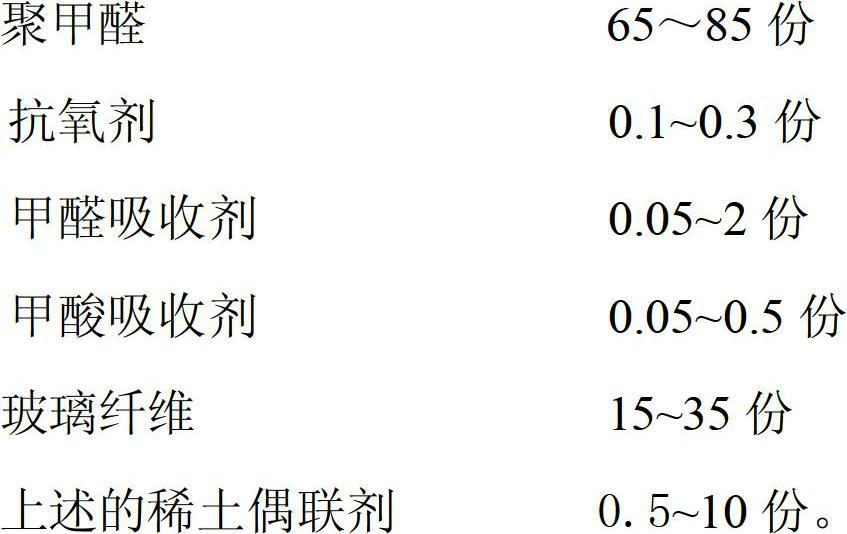

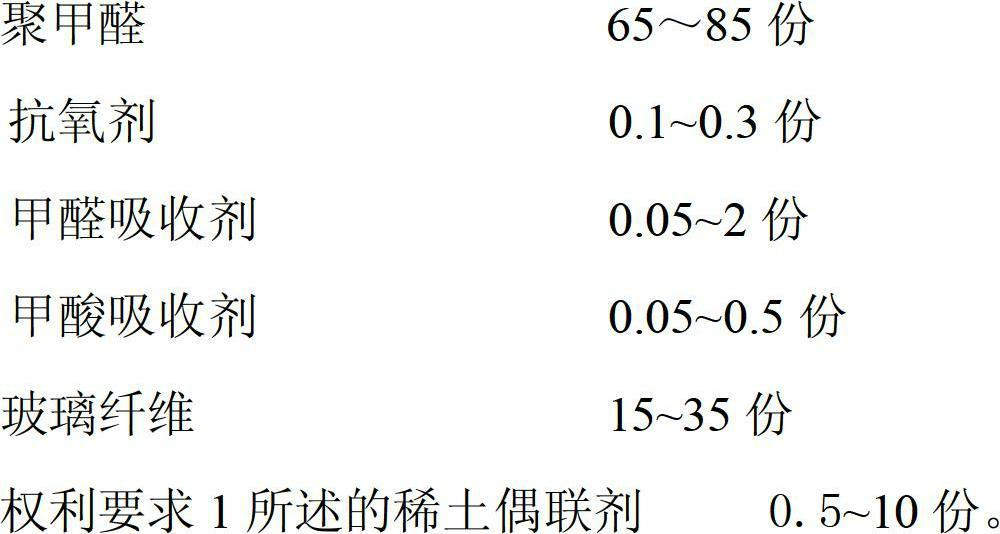

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Synthesis of rare earth coupling agent A:

[0030] Add 100g of rare earth lanthanum oxide into 100g of water to make a slurry, raise the temperature to 40°C, add 150g of polyvinyl alcohol 1788 5% aqueous solution with stirring, raise the temperature to 60°C, then add 100g of sulfuric acid solution with a concentration of 20%, and stir for 15min. Lanthanum sulfate slurry can be prepared.

[0031] Rare earth coupling agent A to treat glass fiber:

[0032] Coat 10Kg of glass fiber with 200g of rare earth coupling agent A slurry on its surface through the slurry dipping tank, squeeze out the residual slurry on the glass fiber surface through extrusion metering rollers, so that the coupling agent can evenly soak into each root glass fiber surface, and then pass the glass fiber bundle impregnated with the coupling agent through a heating cylinder with a length of 50 cm and a temperature of 120 ° C to bake to remove the moisture on the glass fiber surface and the coupling age...

Embodiment 2

[0034] Synthesis of rare earth coupling agent B:

[0035] Add 100g of rare earth cerium oxide into 100g of water to make a slurry, raise the temperature to 40°C, stir and add 150g of 5% aqueous solution of polyvinyl alcohol 1788, raise the temperature to 60°C, then add 100g of sulfuric acid solution with a concentration of 20%, and stir for 15min. Lanthanum sulfate slurry can be prepared.

[0036] Rare earth coupling agent treated glass fiber B:

[0037] Coat 10Kg of glass fiber with 200g of rare earth coupling agent B slurry on its surface through the slurry dipping tank, squeeze out the residual slurry on the glass fiber surface through extrusion metering rollers, so that the coupling agent can evenly soak into each root glass fiber surface, and then pass the glass fiber bundle impregnated with the coupling agent through a heating cylinder with a length of 50 cm and a temperature of 120 ° C to bake to remove the moisture on the glass fiber surface and the coupling agent of ...

Embodiment 3

[0039] Preparation of glass fiber reinforced POM:

[0040] Add 10Kg of POM resin, 30g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 20g of melamine, 20g of calcium carbonate, and 2Kg of glass fiber treated with rare earth coupling agent A Mix in a high-speed mixer, melt and knead with a vented twin-screw extruder, and extrude to granulate. Screw speed, 50 rpm; barrel temperature, 150-200°C. Compared with the POM matrix, the tensile strength of the prepared glass fiber reinforced POM can be doubled, the bending strength can be doubled, the heat distortion temperature can be increased by 60 ℃, and the thermal expansion coefficient can be reduced by 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com