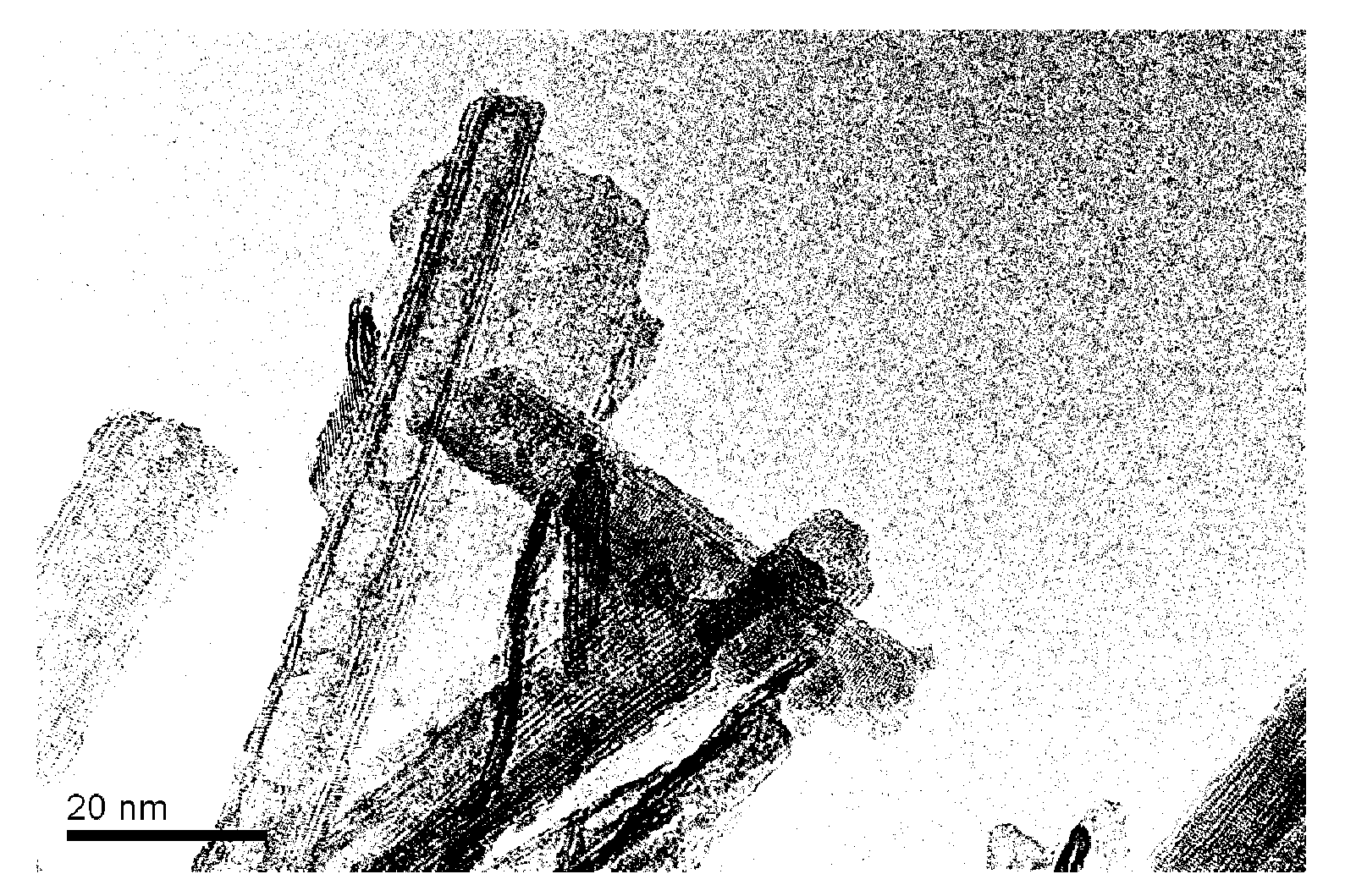

Titanium dioxide nanotube/ graphene composite material and preparation method thereof

A composite material, titanium dioxide technology, applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of affecting photocatalytic performance, low utilization rate of sunlight, and short length of nanotubes, etc., to achieve excellent photocatalytic activity, The preparation process is simple and safe, and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Synthesis of graphene oxide

[0043] Natural graphite (1.5g) was firstly treated with a mixed solution of concentrated sulfuric acid (6mL), potassium persulfate (1.25g) and phosphorus pentoxide (1.25g) in an oil bath at 80°C for early strong protonic acid oxidation treatment, the product After cooling, diluting and filtering, oxidize in a mixed solution of concentrated sulfuric acid (60mL), sodium nitrate (6g) and potassium permanganate (7.5g) at 20-50°C to obtain graphite oxide; After cooling and ethanol dilution, well-dispersed graphite oxide in the solution can be obtained; graphite oxide is ultrasonically stripped (ultrasonic power 1200W, ultrasonic time 300S) to obtain graphene oxide; graphene oxide is subjected to high-speed centrifugation (centrifugal speed 5000 rpm , centrifugation time 600s) to obtain graphene oxide dispersed and stable in the solution, and then suction-filtered and dried at 60°C for 12 hours to obtain graphene oxide powder.

[0044] (2) H...

Embodiment 2

[0048] (1) Synthesis of graphene oxide

[0049] Natural graphite (1.5g) was firstly treated with a mixed solution of concentrated sulfuric acid (8mL), potassium persulfate (1.5g) and phosphorus pentoxide (1.5g) in an oil bath at 90°C for early strong protonic acid oxidation treatment, the product After cooling, diluting and filtering, oxidize in a mixed solution of concentrated sulfuric acid (80mL), sodium nitrate (8g) and potassium permanganate (9g) at 20-50°C to obtain graphite oxide; Cooling and diluting with ethanol can obtain well-dispersed graphite oxide in the solution; ultrasonic exfoliation of graphite oxide (ultrasonic power 800W, ultrasonic time 350S) to obtain graphene oxide; high-speed centrifugation of graphene oxide (centrifugal speed 4000 rpm, Centrifugation time 800S) to obtain graphene oxide dispersed and stable in the solution.

[0050] (2) Hydrothermal reduction of graphene oxide to synthesize nanocomposites

[0051] P25TiO 2 15g of nanoparticles, 12M Na...

Embodiment 3

[0054] (1) Synthesis of graphene oxide

[0055] Natural graphite (1.5g) was firstly treated with a strong protonic acid oxidation treatment with a mixed solution of concentrated sulfuric acid (5mL), potassium persulfate (1g) and phosphorus pentoxide (1g) in an oil bath at 80°C, and the product was cooled After dilution and filtration, oxidize in a mixed solution of concentrated sulfuric acid (50mL), sodium nitrate (5g) and potassium permanganate (6g) at 20-50°C to obtain graphite oxide; cool the obtained graphite oxide, Well-dispersed graphite oxide in the solution can be obtained by diluting with ethanol; ultrasonic exfoliation of graphite oxide (ultrasonic power 1500W, ultrasonic time 150S) to obtain graphene oxide; high-speed centrifugation of graphene oxide (centrifugal speed 6000 rpm, centrifugation time 300S) to obtain graphene oxide dispersed and stable in the solution, and then undergo suction filtration and drying to obtain graphene oxide powder.

[0056] (2) Hydroth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com