Method for producing 9-fluorenone by oxidizing fluorene

A technology of fluorenone and sodium hydroxide, which is applied in the field of deep processing of coal tar products, can solve the problems of high reaction temperature, long reaction time, and high solvent toxicity, and achieve the effects of high purity, short reaction time, and cheap toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

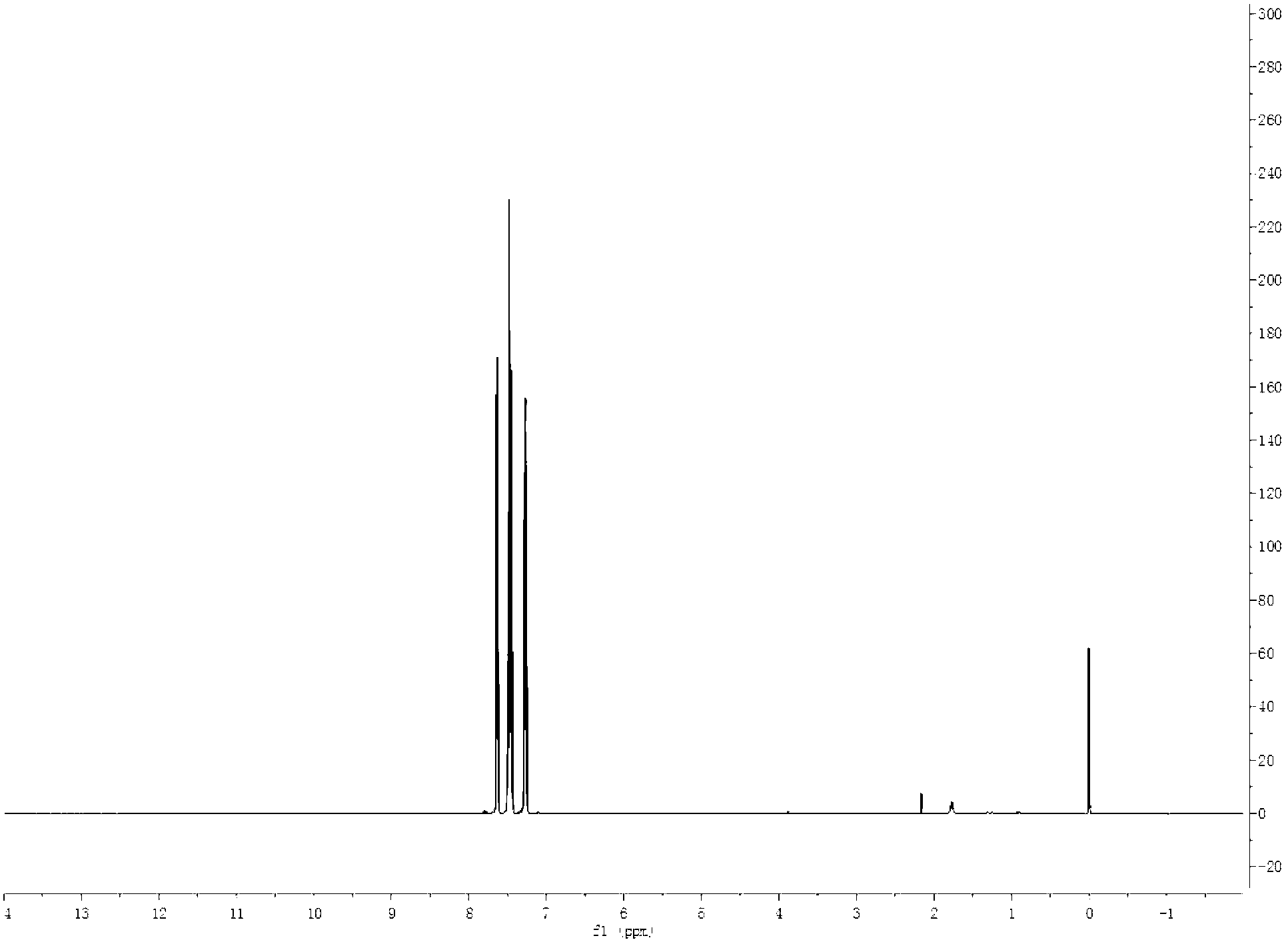

Image

Examples

Embodiment 1

[0023] In this embodiment, fluorene: halogenated hydrocarbon solvent: sodium hydroxide: quaternary ammonium salt is 1:10:10:1. The raw material is about 102 grams of industrial fluorene with a fluorene content of 98%, add 1,000 grams of industrial grade tetrachlorethylene, heat up to 40°C, and add 100 grams of triethylbenzyl ammonium after the solid is completely dissolved, and 2,000 grams of 50% sodium hydroxide aqueous solution , After reacting for 5 hours, the organic solvent was removed by liquid separation. 1000 g of methanol was added to the solid, and the temperature was raised to 50° C. until the solid was dissolved, and air was blown in to react for 5 hours. 800 g of methanol was distilled off under reduced pressure, cooled and crystallized to obtain crystals. The crystals were washed with 80 g of methanol. After drying, it was analyzed by gas chromatography to obtain a fluorenone product with a purity of 99.34%, and the total yield of fluorenone was 90.44%.

Embodiment 2

[0025] In this embodiment, fluorene: halogenated hydrocarbon solvent: sodium hydroxide: quaternary ammonium salt is 1:2:1:0.1. The raw material is 51 grams of industrial fluorene with a fluorene content of 98%, adding 100 grams of industrial grade chloroform as a solvent, raising the temperature to 50 ° C until all the solids are dissolved, adding 5 grams of tetrabutylammonium chloride, 250 grams of 20% sodium hydroxide aqueous solution, After reacting for 0.5 hours, the organic solvent was removed by liquid separation. Add 100 g of ethanol to the solid, raise the temperature to 70° C. until the solid dissolves, and then blow air into it to react for 0.5 hour. 20 g of ethanol was distilled off under reduced pressure, cooled and crystallized to obtain crystals. The crystals were washed with 10 g of ethanol. After drying, it was analyzed by gas chromatography to obtain a fluorenone product with a purity of 99.50%, and the total yield of fluorenone was 88.08%.

Embodiment 3

[0027] In this embodiment, fluorene: halogenated hydrocarbon solvent: sodium hydroxide: quaternary ammonium salt is 1:5:8:0.01. The raw material is 105 grams of industrial fluorene with a fluorene content of 95%, adding 500 grams of solvent industrial grade carbon tetrachloride mixture, raising the temperature to 60°C until the solids are completely dissolved, adding 1 gram of dodecyldimethylbenzyl ammonium, 40% hydrogen Sodium oxide aqueous solution 2000 grams, after reacting for 3 hours, liquid separation removes organic solvent. Add 1000 g of isopropanol to the solid, raise the temperature to 60° C. until the solid dissolves, and then blow air into it to react for 3 hours. 500 g of isopropanol was distilled off under reduced pressure, cooled and crystallized to obtain crystals. The crystals were washed with 50 g of isopropanol. After drying, it was analyzed by gas chromatography to obtain a fluorenone product with a purity of 99.45%, and the total yield of fluorenone was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com