Preparation method of (2S, 3S)-3-amino-N-cyclopropyl-2-hydroxyhexanamide hydrochloride

A technology of hydroxycaproamide and methyl hydroxycaproate, which is applied in the field of preparation of pharmaceutical intermediates, can solve the problems of being unsuitable for large-scale production, unsuitable for industrial production, and unsuitable for large-scale production, and achieves low toxicity and low equipment requirements , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

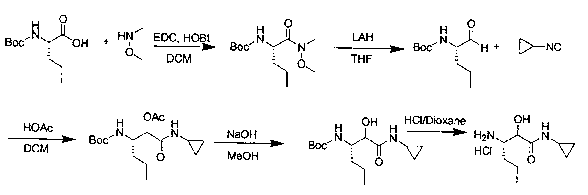

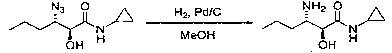

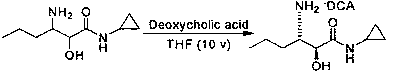

Method used

Image

Examples

Embodiment 1

[0043] Add 457g H to a 1L reaction flask 20, and start stirring, while adding trans-2-hexenoic acid (45.7g, 0.4 mol), cetylpyridinium chloride (13.6g, 0.04 mol), adjust the pH to 6 with 30% aqueous sodium hydroxide solution, at room temperature 30% hydrogen peroxide (91 g, 0.8 mol) was added. Then heated to 50°C for 6 hours until the reaction of the raw materials was complete, cooled to room temperature, adjusted the pH to 2 with concentrated hydrochloric acid, extracted twice with 400g of dichloromethane, and concentrated to dryness to obtain 48.6g of 3-propyl oxirane -2-Formic acid (formula II), yield 92%.

[0044] In the above examples, the catalyst uses sodium tungstate or 12-phosphotungstic acid instead of cetylpyridinium chloride, and the lye is ammonia water, sodium carbonate solution, potassium carbonate solution, potassium hydroxide solution, sodium phosphate solution, One of potassium phosphate solution, sodium bicarbonate solution or potassium bicarbonate solution...

Embodiment 2

[0046] Add 140g H to a 1L reaction flask 2 O, and start stirring, while adding trans-2-hexenoic acid (45.7g, 0.4 mol), sodium tungstate (26.4g, 0.08mol), adjust the pH to 5 with aqueous sodium carbonate solution, add 30% hydrogen peroxide at room temperature (113.7g, 1.0 mol), then heated to 60°C for 5 hours until the reaction of the raw materials was complete, cooled to room temperature, adjusted the pH to 1 with concentrated hydrochloric acid, extracted twice with 400g dichloromethane, concentrated to dryness, and obtained 47.5g 3- Propyloxirane-2-carboxylic acid (formula II), yield 90%.

Embodiment 3

[0048] Add 320g H to a 1L reaction flask 2 O, and start stirring, while adding trans-2-hexenoic acid (45.7g, 0.4 mol), cetylpyridinium chloride (20.4g, 0.06 mol), adjust pH to 5.5 with aqueous sodium carbonate solution, add 30% Hydrogen peroxide (102.4g, 0.9mol), then heated to 55°C and reacted for 5.5 hours until the reaction of the raw materials was complete, cooled to room temperature, adjusted the pH to 1.5 with concentrated hydrochloric acid, extracted twice with 400g of dichloromethane, concentrated to dryness, and obtained 49.6g of 3 -Propyloxirane-2-carboxylic acid (formula II), yield 94%.

[0049] Preparation of Propyloxirane-2-carboxylic acid (Formula III)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com