Fluorescent sensor based on cellulose nanometer micro-fiber (TOCN) film serving as substrate and application thereof

A fluorescence sensor and nano-fiber technology, applied in the direction of fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems such as glass sheet and quartz sheet are not easy to carry, difficult to control the film thickness, pollute the system to be tested, etc., and achieve reusable portable , the effect of suppressing π-π stacking and improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

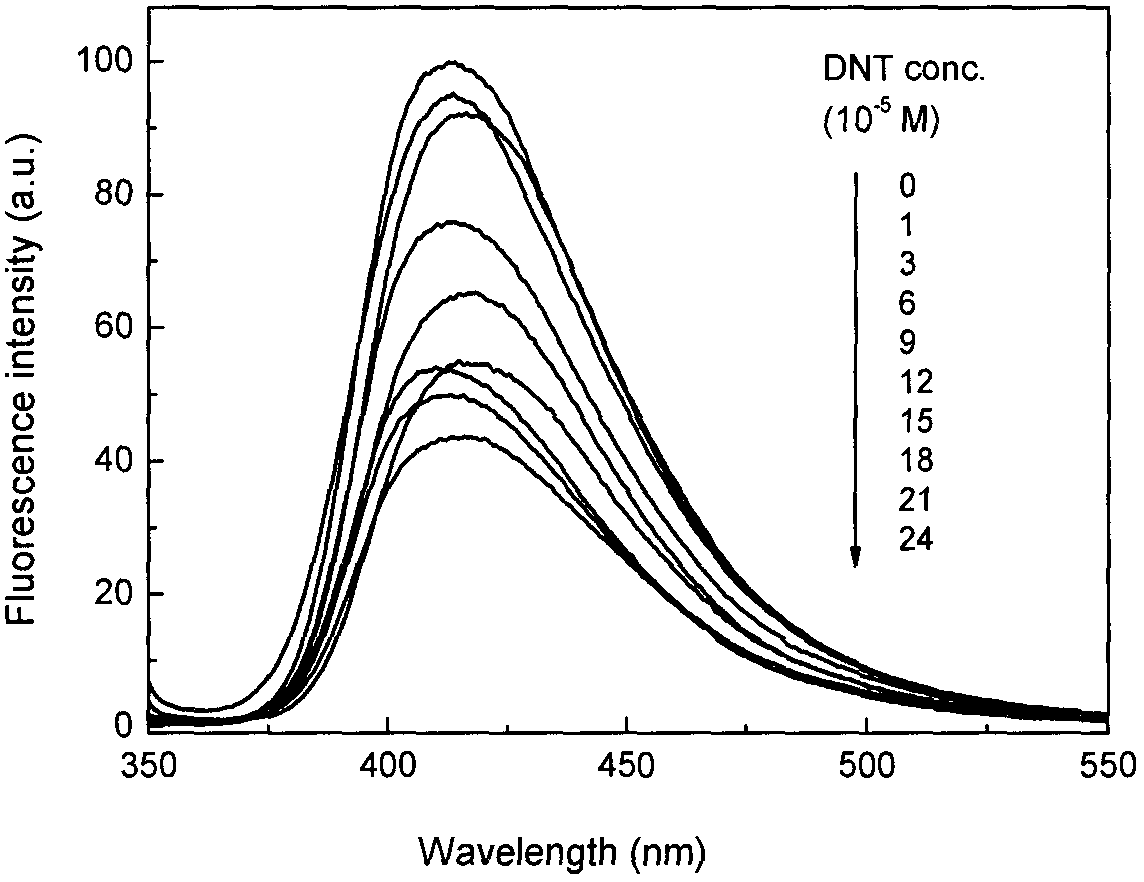

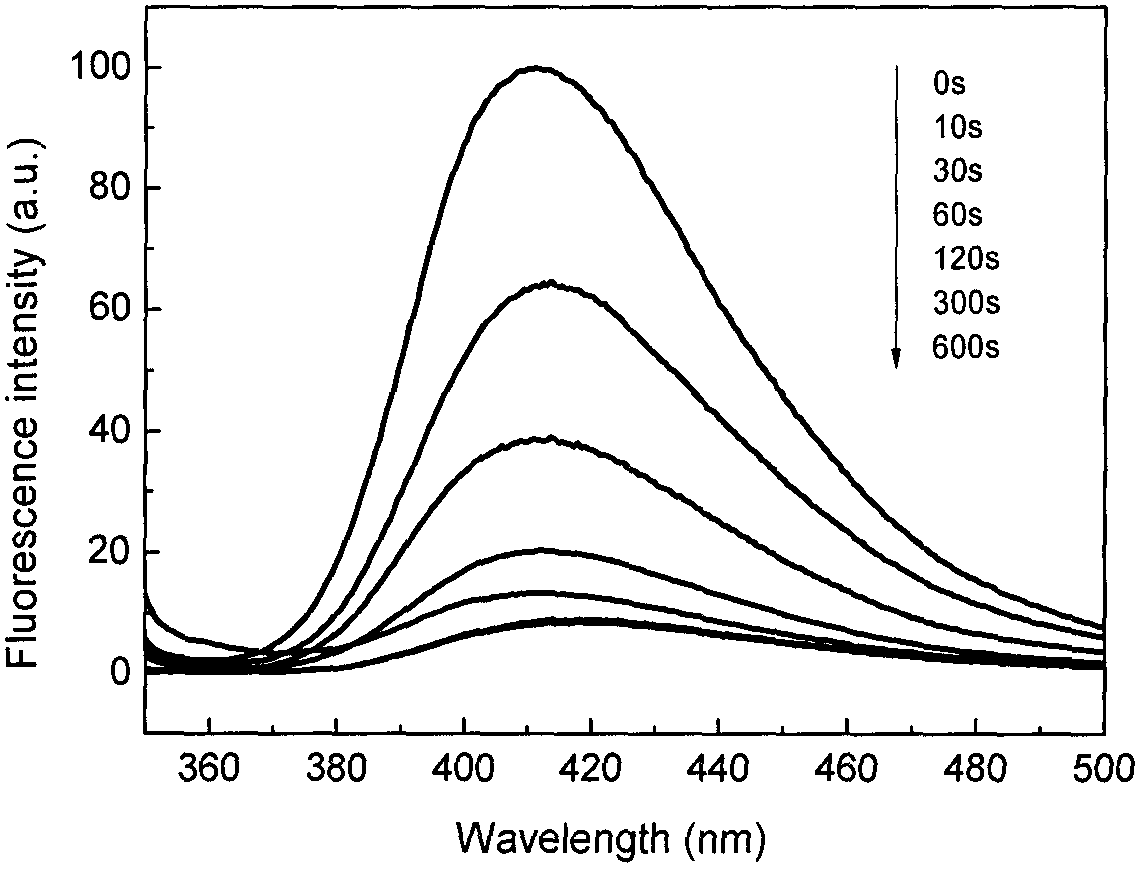

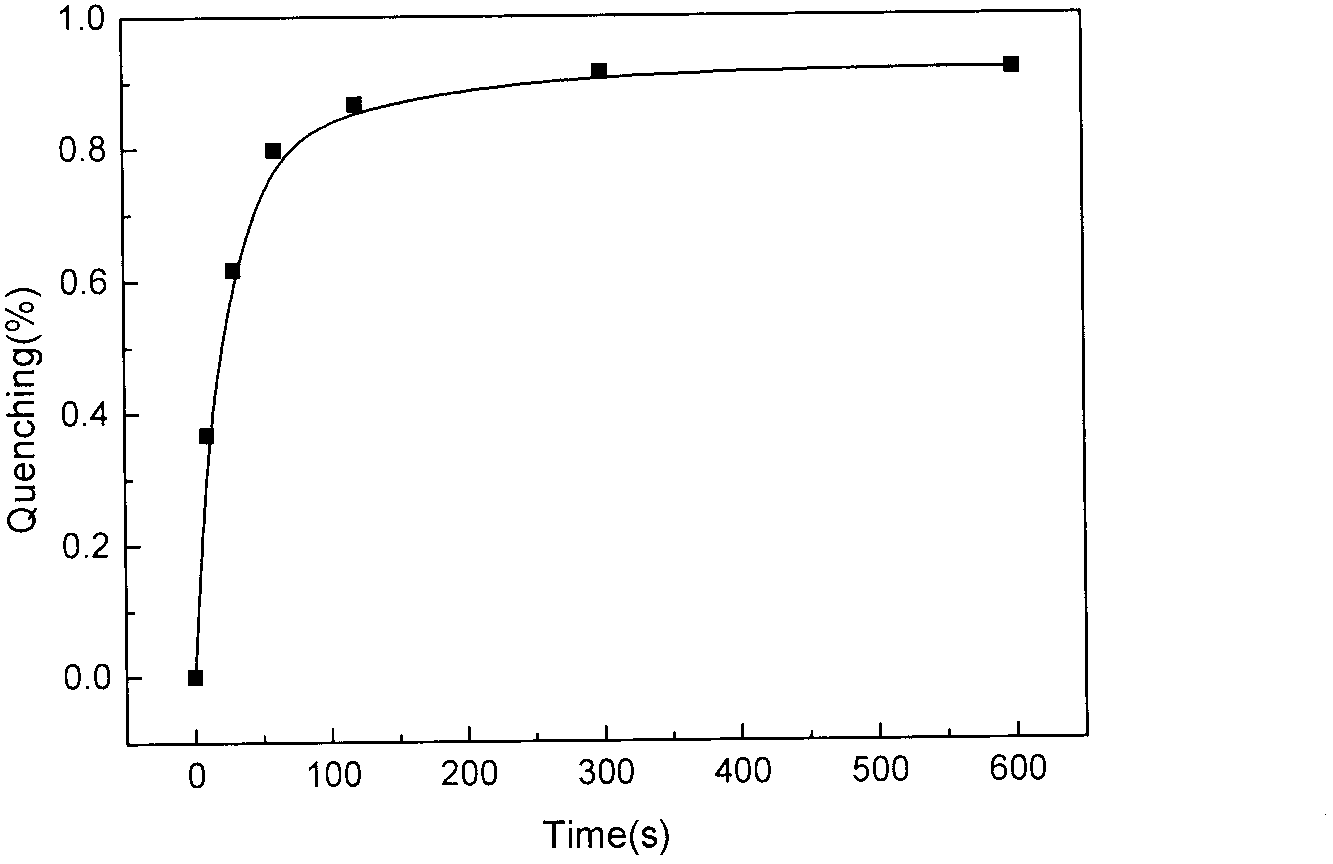

Examples

Embodiment 1

[0028] (1) Weigh 0.1g TEMPO and 1gNaBr into 500mL deionized water, stir fully at room temperature; after TEMPO and NaBr are completely dissolved, add 10g wet wood pulp cellulose (the mass fraction of cellulose is 20.15%) to the reaction system After the cellulose is dispersed evenly, add 20g of NaClO solution to the system, and control the pH value of the reaction system in the range of 10 to 10.5; pH value of the system, until the NaOH solution is no longer consumed, the reaction is over; filter in a sand core funnel, and wash 3 to 5 times to prepare oxidized cellulose; supernatant and centrifuge the prepared oxidized cellulose, and take the upper layer Clear liquid, obtain TOCN solution. Ultrasonic defoaming of the TOCN aqueous suspension to obtain a casting solution, wherein the mass fraction of TOCN is 0.2% to 0.3%; the resulting casting solution is poured into a polytetrafluoroethylene mold, and after standing for 10min to 1h, put it in 30 Place in an oven at ~70°C for 6...

Embodiment 2

[0034](1) Ultrasonic defoaming of the TOCN aqueous suspension to obtain a casting solution, wherein the mass fraction of TOCN is 0.2% to 0.3%; the resulting casting solution is poured into a mold made of polytetrafluoroethylene, and left to stand for 10min to 1h Finally, put it in an oven at 30-70°C for 6-10 hours, and get a TOCN film after the solvent is completely evaporated.

[0035] (2) Put the TOCN film into the morpholine ethanesulfonic acid buffer solution with a pH of 4 to 7, add the condensing agent 1-(3-dimethylaminopropyl)-3-ethylcarbodiamine / N-hydroxy The molar ratio of succinimide is 2:1. After 30 minutes, add the DMF solution of p-bromoaniline. After reacting for 16 hours, wash with water and ethanol repeatedly, and vacuum-dry the obtained film to obtain a TOCN active film capable of Suzuki reaction.

[0036] (3) Dissolve 3,6-dibromocarbazole and 9,9-dihexylfluorene-2,7-diborate in tetrahydrofuran at a molar ratio of 1:1, and add 1 to 3 mol / L of K 2 CO 3 Aque...

Embodiment 3

[0040] (1) Ultrasonic defoaming of the TOCN aqueous suspension to obtain a casting solution, wherein the mass fraction of TOCN is 0.2% to 0.3%; the resulting casting solution is poured into a mold made of polytetrafluoroethylene, and left to stand for 10min to 1h Finally, put it in an oven at 30-70°C for 6-10 hours, and get a TOCN film after the solvent is completely evaporated.

[0041] (2) Put the TOCN film into the morpholine ethanesulfonic acid buffer solution with a pH of 4 to 7, add the condensing agent 1-(3-dimethylaminopropyl)-3-ethylcarbodiamine / N-hydroxy The molar ratio of succinimide is 2:1. After 30 minutes, add the DMF solution of p-bromoaniline. After reacting for 16 hours, wash with water and ethanol repeatedly, and vacuum-dry the obtained film to obtain a TOCN active film capable of Suzuki reaction.

[0042] (3) Dissolve 3,6-dibromocarbazole and 9,9-dihexylfluorene-2,7-diborate in tetrahydrofuran at a molar ratio of 1:1, and add 1 to 3 mol / L of K 2 CO 3 Aqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com