Method for preparing gradient-controllable colloidal photonic crystal

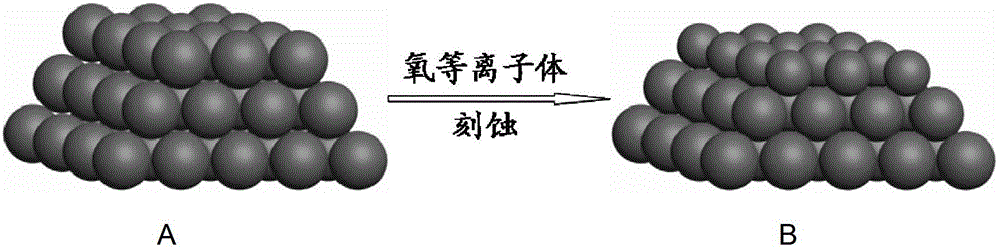

A colloidal photonic crystal and gradient technology, applied in the field of materials, can solve problems such as difficulty in obtaining photonic modes, and achieve the effect of simple operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of hydrophilic silicon chip

[0027] The silicon wafer used is a single crystal silicon wafer (100), cut the silicon wafer to a size of 4cm long and 3cm wide with a glass knife, and put it into a mixed solution of concentrated sulfuric acid (98% by mass fraction) and hydrogen peroxide (30% by mass fraction) (Volume ratio is 7:3) heated to 80°C in a water bath and kept for 5 hours to obtain a hydrophilic silicon wafer; then pour the mixed solution into a waste liquid bottle, and repeatedly wash the obtained hydrophilic silicon wafer with deionized water 3 to 5 times, stored in deionized water for later use.

Embodiment 2

[0028] Embodiment 2: the purification of monomer and initiator

[0029] Put styrene and 10wt% sodium hydroxide aqueous solution into the separatory funnel, shake to make the polymerization inhibitor (hydroquinone) in styrene react with sodium hydroxide to generate the sodium salt of hydroquinone, separate liquid Afterwards, wash repeatedly 3 times until colorless; then wash with distilled water to pH = 7, and remove water with anhydrous sulfuric acid; collect fractions by vacuum distillation, methyl methacrylate and acrylic acid direct vacuum distillation to collect fractions.

[0030] Dissolve ammonium persulfate in deionized water at 40°C, filter and cool the filtrate with ice, and then filter after crystallization, repeat the filter 3 times, and dry it at room temperature for later use.

Embodiment 3

[0031] Embodiment 3: the preparation of diameter 253nm P (St-MMA-AA) microsphere

[0032] Install the electromagnetic stirrer, condenser tube, and nitrogen tube into a 250mL three-necked flask, and add 120mL of deionized water after purging nitrogen to exhaust the air; dissolve 0.42g of ammonium persulfate and 0.8g of ammonium bicarbonate in deionized water; The volume ratio of pressure distillation is 90:5:5 styrene, methyl methacrylate, acrylic acid monomer mixture. After passing nitrogen to remove oxygen, heat up to 70°C in a water bath at a stirring speed of 400rpm, and react stably for 7 hours under a nitrogen atmosphere; after the polymerization is completed, the unpolymerized monomers are volatilized under continuous stirring, and the colloid particles agglomerated in the emulsion are removed by suction filtration. Balls were centrifuged and washed with water three times to remove impurities to obtain P(St-MMA-AA) microspheres with a diameter of 253nm.

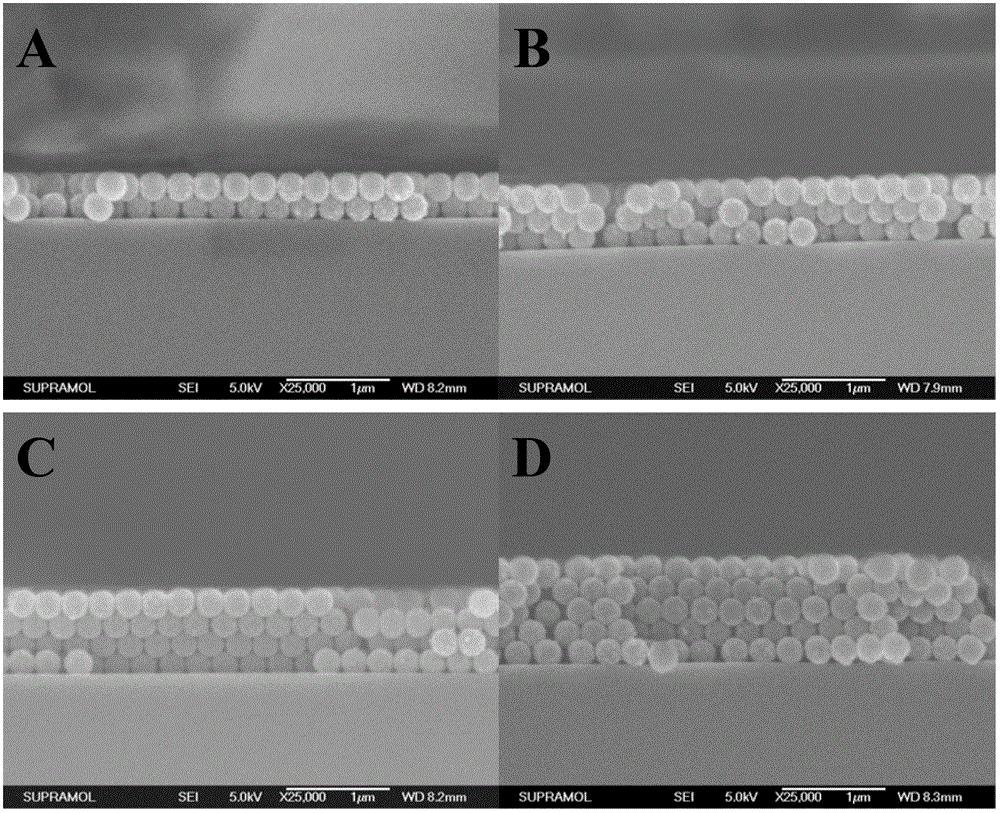

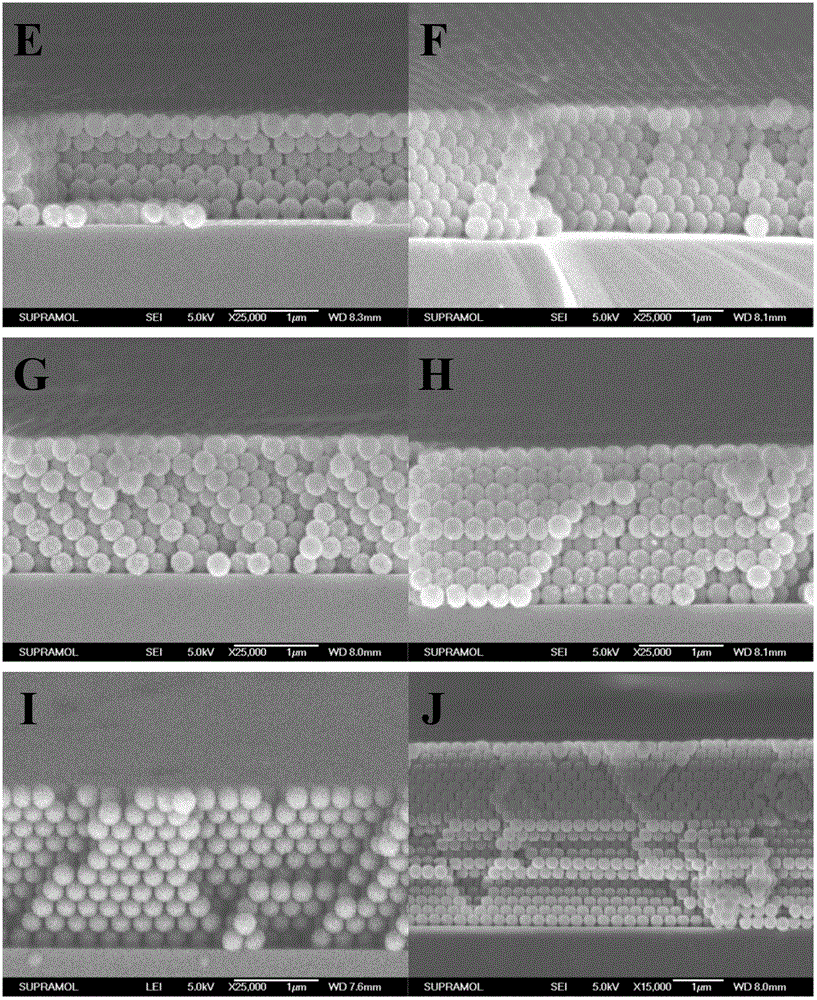

[0033]For micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com