Phase change vanadium dioxide film prepared by rapid thermal oxidation method

A vanadium dioxide and thermal oxidation technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of unstable vanadium dioxide, poor experimental controllability, and many control parameters, etc. The effect of time and cycle reduction, less control parameters, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Cutting the silicon wafer into small silicon wafers with a size of 2cm×2cm, soaking them in absolute ethanol solution, adopting standard silicon wafer cleaning process, ultrasonic cleaning, cleaning with deionized water, and drying;

[0023] (2) Place the sample cleaned in step (1) in the vacuum chamber of the DPS-Ⅲ ultra-high vacuum target magnetron sputtering coating machine, and vacuum the body by 2.5×10 -4 Pa; Introduce argon gas with a purity of 99.999%, the flow rate of argon gas is 50sccm, and adjust the working pressure to 2.0Pa; first perform pre-sputtering to remove dirt on the target surface, sputtering power is 165w, and start deposition after pre-sputtering Metal vanadium film, sputtering time is 10min;

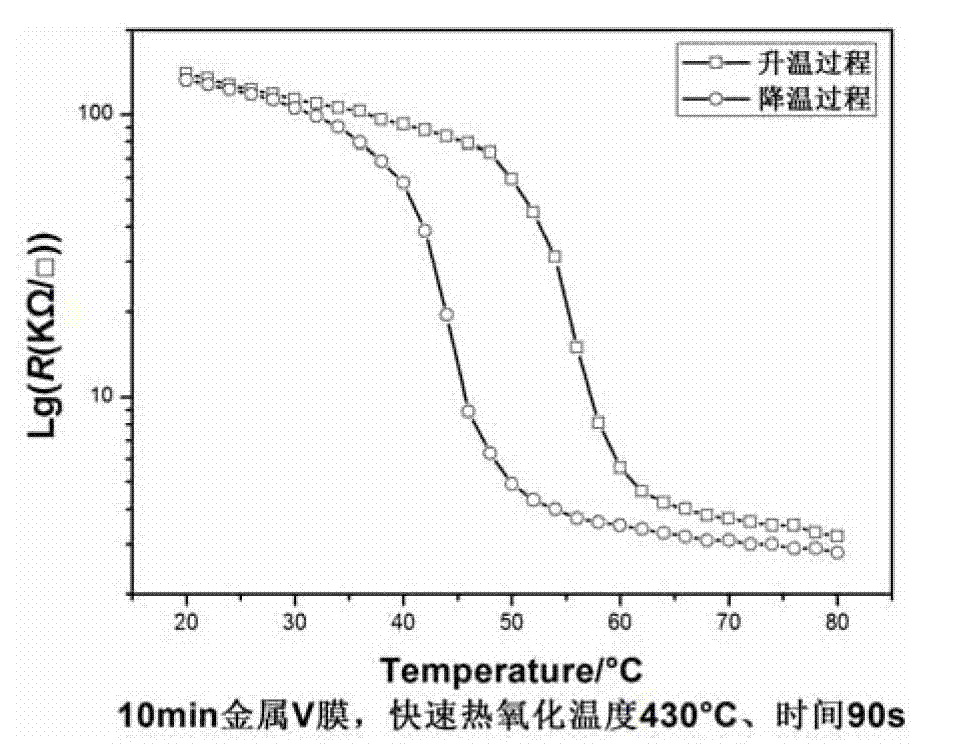

[0024] (3) put the metal vanadium thin film of step (2) into the AG610 type rapid heat treatment equipment produced by Allwin21corp.USA company, the rapid thermal oxidation temperature is 430 ° C, the rapid thermal oxidation time is 90s; the heating ra...

Embodiment 2

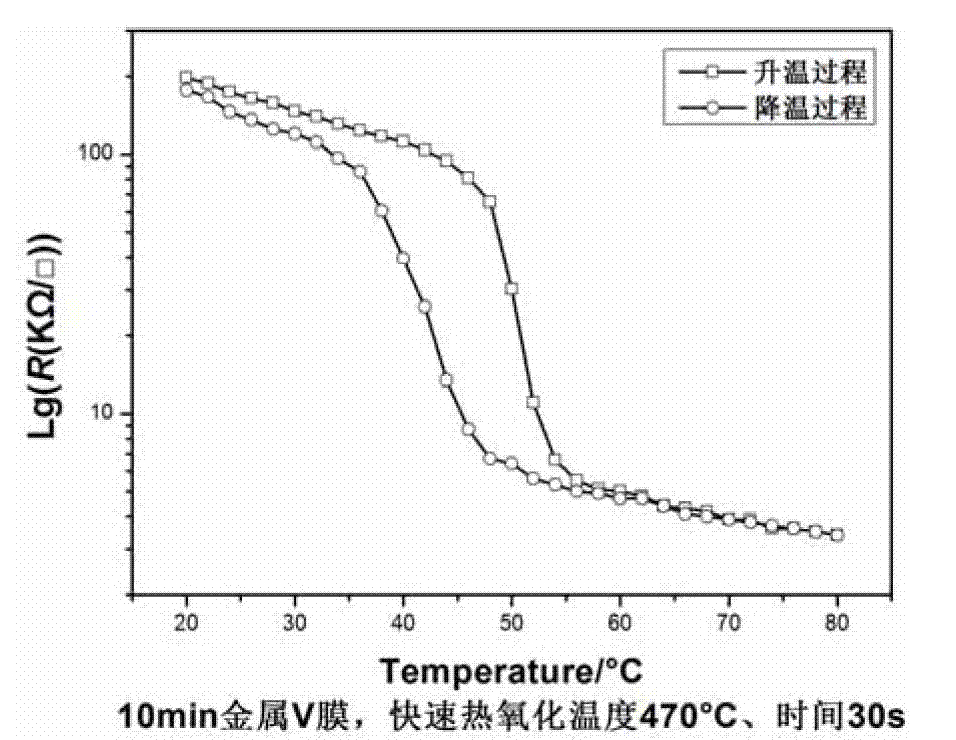

[0028] The operation steps are the same as in Example 1, the process conditions of step (2) are: sputtering time 10min; the working gas in the rapid thermal oxidation process of step (3) is oxygen, the rapid thermal oxidation temperature is 470°C, and the rapid thermal oxidation time is 30s;

[0029] The vanadium dioxide film prepared in Example 2 has a measured sheet resistance of 197.2KΩ / □ at a temperature of 20°C, and a measured sheet resistance of 3.4KΩ / □ at a temperature of 80°C. The temperature coefficient of resistance of the vanadium oxide film is -1.63×10 -2 K -1 .

[0030] The resistance-temperature curve of embodiment 2 is as figure 2 shown by figure 2 It can be seen that the prepared vanadium dioxide thin film has phase change properties.

Embodiment 3

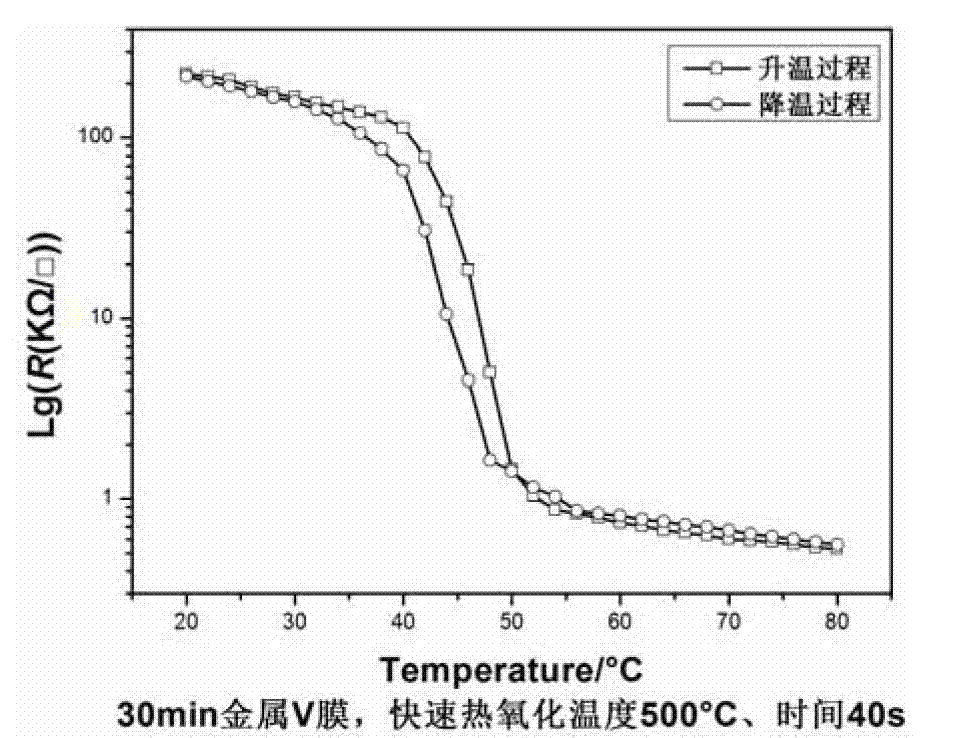

[0032] The operation steps are the same as in Example 1, the process conditions of step (2) are: sputtering time 30min; the working gas in the rapid thermal oxidation process of step (3) is oxygen, the rapid thermal oxidation temperature is 500°C, and the rapid thermal oxidation time is 40s;

[0033] The vanadium dioxide film prepared in Example 3 has a measured sheet resistance of 225.8KΩ / □ at a temperature of 20°C, and a measured sheet resistance of 0.53KΩ / □ at a temperature of 80°C. The temperature coefficient of resistance of the vanadium dioxide film is -1.66×10 -2 K -1 .

[0034] The resistance-temperature curve of embodiment 3 is as image 3 shown by image 3 It can be seen that the prepared vanadium dioxide thin film has phase change properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com