Preparation method of targeting composite nanoparticle

A nanoparticle and composite technology, which is applied in the research field of hydroxycamptothecin-loaded targeted nanoparticles, can solve the problems of drugs that can only be dissolved in acetonitrile, drug stability, encapsulation efficiency, product drug loading The problem of low dosage and encapsulation efficiency can be achieved to prolong the effective time of action, promote the combination, and achieve the effect of large drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Dissolve PLGA in an organic solvent with a volume ratio of dichloromethane: ethanol = 3:1 to form an organic solution with a concentration of 50 mg / mL. The mass ratio of lecithin and polyethylene glycol-distearoylphosphatidylethanolamine is 9: 1 Dissolve in the above organic solution, and add it dropwise to 2 times the volume of ultrapure water, use an ultrasonic cell breaker with a power of 7W, ultrasonic for 30 seconds, then add the emulsion to 2 times the volume of ultrapure water, continuously Stir for 3 hours to remove the organic solvent, solidify and shape the composite nanoparticles, and finally collect by centrifugation, wash with ultrapure water three times, and freeze-dry to obtain composite nanoparticles.

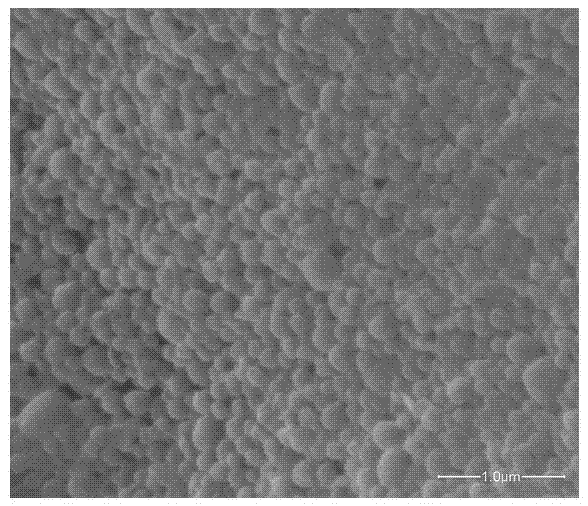

[0034] Laser particle size analysis showed that the obtained nanoparticles were normally distributed with an effective diameter of 357 nm and a polydispersity of 0.268. Observed under a scanning electron microscope, the nanoparticles have a regular spheric...

Embodiment 2

[0036] Dissolve PLGA in an organic solvent with a volume ratio of dichloromethane: ethanol = 4:1 to form an organic solution with a concentration of 40 mg / mL, lecithin and polyethylene glycol-distearoylphosphatidylethanolamine in a mass ratio of 7: 3 Dissolve in the above organic solution, add it dropwise to 2 times the volume of ultrapure water, use an ultrasonic cell breaker with a power of 9W, ultrasonicate for 60 seconds, then add the emulsion to 2 times the volume of ultrapure water, and continue stirring for 3 hours The organic solvent is removed, the composite nanoparticles are solidified and formed, finally collected by centrifugation, washed three times with ultrapure water, and freeze-dried to obtain composite nanoparticles.

[0037] Laser particle size analysis showed that the obtained nanoparticles were normally distributed with an effective diameter of 337 nm and a polydispersity of 0.228. Observed under a scanning electron microscope, the nano-microspheres have a...

Embodiment 3

[0039] Dissolve PLGA in an organic solvent with a volume ratio of dichloromethane: ethanol = 5:1 to form an organic solution with a concentration of 30 mg / mL, lecithin and polyethylene glycol-distearoylphosphatidylethanolamine in a mass ratio of 5: 5 Dissolve in the above organic solution, add it dropwise to 4 times the volume of ultrapure water, use an ultrasonic cell disruptor with a power of 11W, and ultrasonicate for 120 seconds, then add the emulsion to 4 times the volume of ultrapure water, and continue stirring for 3 hours The organic solvent is removed, the composite nanoparticles are solidified and formed, finally collected by centrifugation, washed three times with ultrapure water, and freeze-dried to obtain composite nanoparticles.

[0040] Laser particle size analysis showed that the obtained nanoparticles were normally distributed with an effective diameter of 305 nm and a polydispersity of 0.186. Observed under a scanning electron microscope, the nano-microsphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com