Solar battery encapsulation adhesive film

A technology for solar cells and encapsulation films, applied in circuits, adhesives, photovoltaic power generation, etc., can solve problems such as shortening the service life of the film, yellowing of the film, affecting the photoelectric conversion efficiency of solar cells, and reducing the aging yellowing index. , high and low temperature aging resistance, and the effect of moisture and freezing aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The ratio of raw materials of the present invention is calculated in the following parts by weight.

[0046] Basic raw material: ethylene-vinyl acetate copolymer-100 parts; the present invention has specific requirements for the content of vinyl acetate in the ethylene-vinyl acetate copolymer, if the content of vinyl acetate in the ethylene-vinyl acetate copolymer is too high (usually ≥ 40%), the viscosity of ethylene-vinyl acetate copolymer will decrease, the strength will decrease, and the polarity will increase, resulting in easy flow out of the solar cell module during use, and will affect the tear resistance of the solar cell module during use cracking; if the vinyl acetate content in the ethylene-vinyl acetate copolymer is too low (usually <25%), the processing performance will be reduced, the finished film will become too hard, and it will not be easy to defoam during the manufacture of solar cell modules; therefore, The vinyl acetate content in the ethylene-viny...

Embodiment 2

[0054] The ratio of raw materials of the present invention is calculated in the following parts by weight.

[0055] Basic raw material: ethylene-vinyl acetate copolymer-100 parts, the content of vinyl acetate in ethylene-vinyl acetate copolymer is 30%;

[0056] Organic peroxide: o-tert-butyl-o-isopropyl-mono-peroxycarbonate-0.6 part;

[0057] UV absorber: 2-hydroxy-4-methoxybenzophenone-0.2 part, 2-hydroxy-4-dodecyloxybenzophenone-0.2 part, 2,4-dihydroxybenzophenone -0.2 copies;

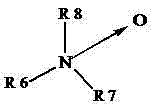

[0058] Light stabilizers: N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,6-hexanediamine and 2,4-dichloro-6-(1, 1,3,3-tetramethylbutyl) amino-1,3,5-triazine polymer - 0.3 parts;

[0059] Antioxidant: tetrakis (2,4-di-tert-butylphenyl-4,4'-biphenyl) bisphosphite - 0.1 part, pentaerythyl stearyl diphosphite - 0.1 part;

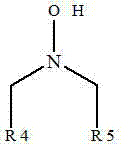

[0060] Carbon free radical scavenger: N,N-di(octadecyl)hydroxylamine-0.7 parts.

[0061] According to the preparation method of Example 1, the test ethylene-vinyl acetate copolymer...

Embodiment 3

[0063] The ratio of raw materials of the present invention is calculated in the following parts by weight.

[0064] Basic raw material: ethylene-vinyl acetate copolymer-100 parts, the content of vinyl acetate in ethylene-vinyl acetate copolymer is 28%;

[0065] Organic peroxides: o-tert-butyl-o-(2-ethylhexyl)-mono-peroxycarbonate-0.5 parts, o-tert-butyl-o-isopropyl-mono-peroxycarbonate Esters - 0.5 parts;

[0066] UV absorber: 2-hydroxy-4-n-octyloxybenzophenone-0.1 part, 2-hydroxy-4-acryloyloxyethoxybenzophenone-0.1 part;

[0067] Light stabilizers: N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,6-hexanediamine and 2,4-dichloro-6-(1, 1,3,3-tetramethylbutyl) amino-1,3,5-triazine polymer - 0.1 parts;

[0068] Antioxidant: pentaerythritol bisphosphite bis(2,4-di-tert-butylphenyl)-0.07 part, tris(nonylphenyl)phosphite-0.07 part;

[0069] Carbon free radical scavenger: N,N,-dihydrogenated rapeseed oil alkyl-N-methyl nitrogen oxide-1 part.

[0070] According to the preparation m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com