Preparation method of ZnS-cladded ZnO nanoarray core-shell structure

A nano-array, core-shell structure technology, applied in sputtering plating, ion implantation plating, final product manufacturing, etc., to achieve the effect of improving transmission capacity, stable deposition rate, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

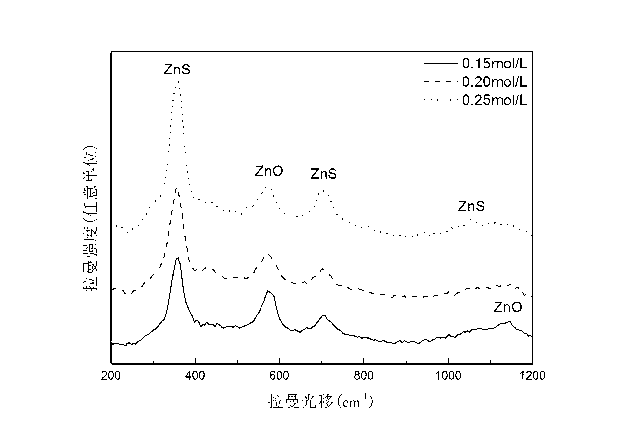

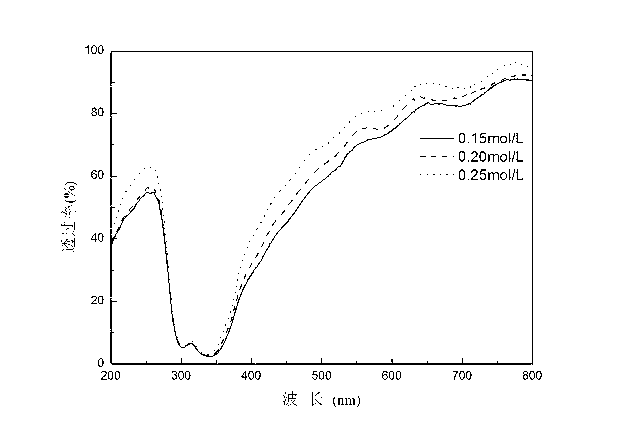

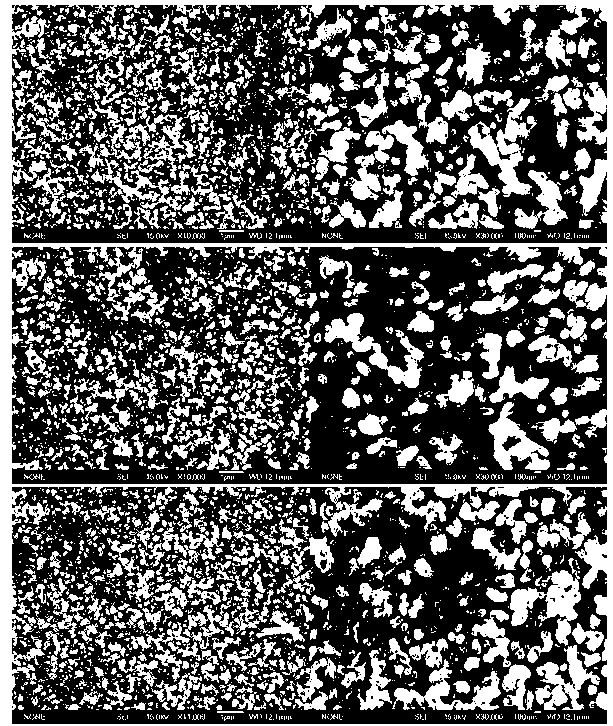

Image

Examples

Embodiment 1

[0027] 1. Cleaning of glass substrate

[0028] Carry out surface cleaning treatment on the FTO conductive glass, put in triton aqueous solution, acetone solution, absolute alcohol solution and deionized water in sequence for 15 minutes, and then dry the FTO substrate.

[0029] 2. Preparation of ZnO seed crystals

[0030] ZnO seeds were prepared by magnetron sputtering. The target material is Al-doped 2 o 3 ZnO target (AZO target), in which ZnO is 98wt%, Al 2 o 3 is 2wt%. The magnetron sputtering condition is: the background vacuum is 5×10 -4 Pa, the working pressure is 0.4Pa, the radio frequency sputtering power is 150W, and the sputtering time is 20min. The seeds were heat-treated in a rapid annealing furnace in N 2 It is carried out in the atmosphere, the temperature is 400°C, and the time is 20 minutes.

[0031] 3. Growth of ZnO nanoarrays

[0032] ZnO nanoarrays were grown by hydrothermal method. The growth solution is an aqueous solution of 0.05mol / L zinc nitra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com