High-transparent ultraviolet separation ceramic-imitating flexible nanometer composite membrane material and preparation method thereof

A nano-composite and transparent violet technology, which is applied in the field of high-transparency UV-blocking imitation ceramic flexible nano-composite film materials and its preparation, can solve the problems of reduced transparency and optical uniformity, insufficient flexibility, and energy instability. The effect of optical uniformity, simple process and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Get the ZnO nanoparticle ethanol dispersion (initial dispersion, solvent A is ethanol), drop a large amount of isopropyl ether (solvent B), obtain white ZnO precipitate, centrifuge, then place the vacuum drying oven to dry the precipitate after washing three times, Obtain ZnO nanopowder. 1.0 g of ZnO nanopowder was dispersed into 1.7 g of butyl methacrylate under the action of magnetic stirring and ultrasonic waves to realize phase transfer of ZnO nanoparticles. Add 0.2wt% AIBN of the total mass of the dispersion, stir evenly and defoam, pour the liquid into the mold, polymerize in an oven at 78°C for 6 hours, then polymerize at 65°C for 16 hours, and finally at 95°C and 115°C Under heat treatment for 1 hour and 1 hour, a transparent and flexible nanocomposite film material is obtained after demoulding. The thickness of the film is 4.0 mm, and the optical performance test results are shown in Table 1.

[0043] Visible light transmittance (%) (550nm)

[0044]...

Embodiment 2

[0046] 1.0 g of ZnO nanopowder obtained in Example 1 was dispersed into 1.7 g of butyl methacrylate under the action of magnetic stirring and ultrasonic waves to realize phase transfer of ZnO nanoparticles. Add 0.5wt% AIBN of the total mass of the dispersion, stir evenly and defoam, pour the liquid into the mold, polymerize in an oven at 78°C for 6 hours, then polymerize at 65°C for 16 hours, and finally at 95°C and 115°C After heat treatment for 1 hour, a transparent and flexible nanocomposite film material is obtained after demoulding. The thickness of the film is 4.0 mm, and the test results of its optical properties are shown in Table 2.

[0047] Visible light transmittance (%) (550nm)

[0048] Table 2

Embodiment 3

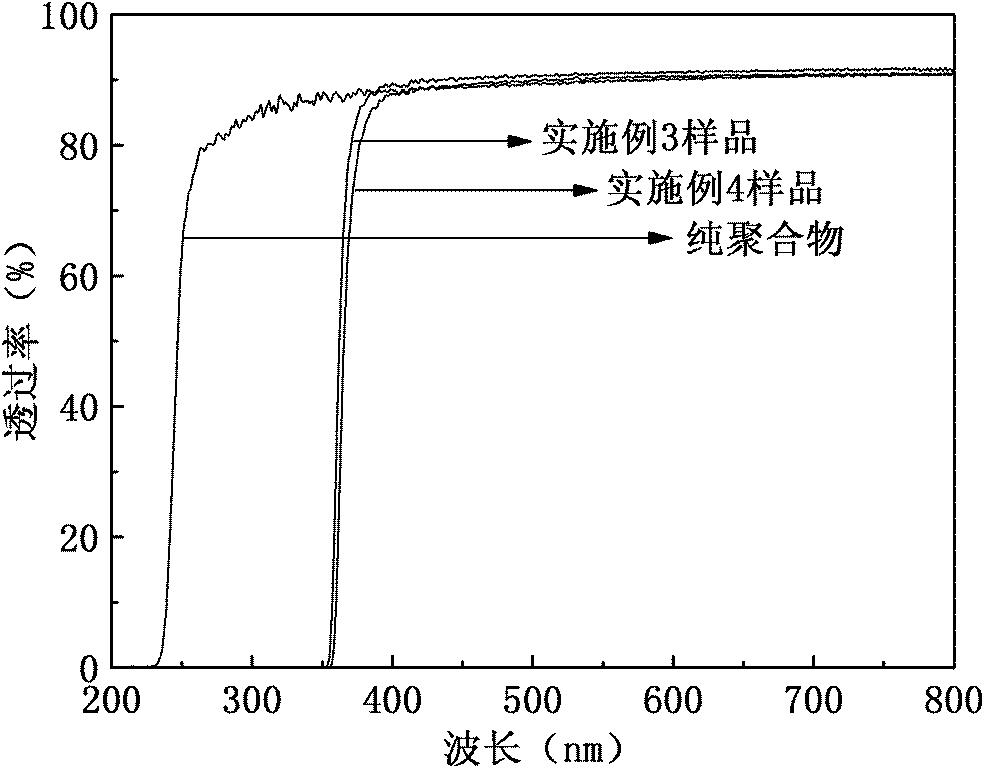

[0050] 1.0 g of ZnO nanopowder obtained in Example 1 was dispersed into 1.7 g of 3-methacryloxypropyltrimethoxysilane under the action of magnetic stirring and ultrasonic waves to realize phase transfer of ZnO nanoparticles. Add 0.5wt% AIBN of the total mass of the dispersion, stir evenly and defoam, pour the liquid into the mold, polymerize in an oven at 78°C for 6 hours, then polymerize at 65°C for 16 hours, and finally at 95°C and 115°C After heat treatment for 1 hour, a transparent and flexible nanocomposite film material is obtained after demoulding. The thickness of the film is 0.070mm, and the test results of its optical properties are shown in Table 3. See image 3.

[0051] Visible light transmittance (%) (550nm)

[0052] table 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com