High activity catalyst used for synthesizing ultrahigh molecular weight polyethylene and preparation method

A high-activity catalyst and ultra-high molecular weight technology, applied in the production of bulk chemicals, etc., can solve the problems of difficult use and recovery of liquid titanium compounds, difficult control of particle size and particle size distribution, and poor particle shape of solid catalysts, so as to achieve easy polymerization Effects of process control, ease of polymerization control, ease of polymerization control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Catalyst preparation:

[0051] First replace the 250ml three-necked flask with a heating system and equipped with a stirring device and a reflux condensing system with nitrogen for no less than three times, then add 60ml of n-hexane, 1g of anhydrous magnesium chloride, and stir to raise the temperature (temperature setting 65°C); then Add 5ml of n-butanol and stir for 0.3 hours to obtain a magnesium alkoxide compound solution; after cooling to room temperature, slowly add 2.8×10 -4 mol of diethylaluminum chloride, reflux at 65°C for 1 hour; after cooling to room temperature, slowly add 4×10 -4 mol titanium tetrachloride, react at a constant temperature of 70°C for 0.5 hours; turn on the ultrasonic device, adjust the frequency to 40KHz, and the power of the device to 50W, and maintain it for 1min. After the ultrasonic device was turned off, the reaction system was kept at 70°C for 2 hours at a constant temperature; finally, the stirring was stopped, and the mother liquo...

Embodiment 2

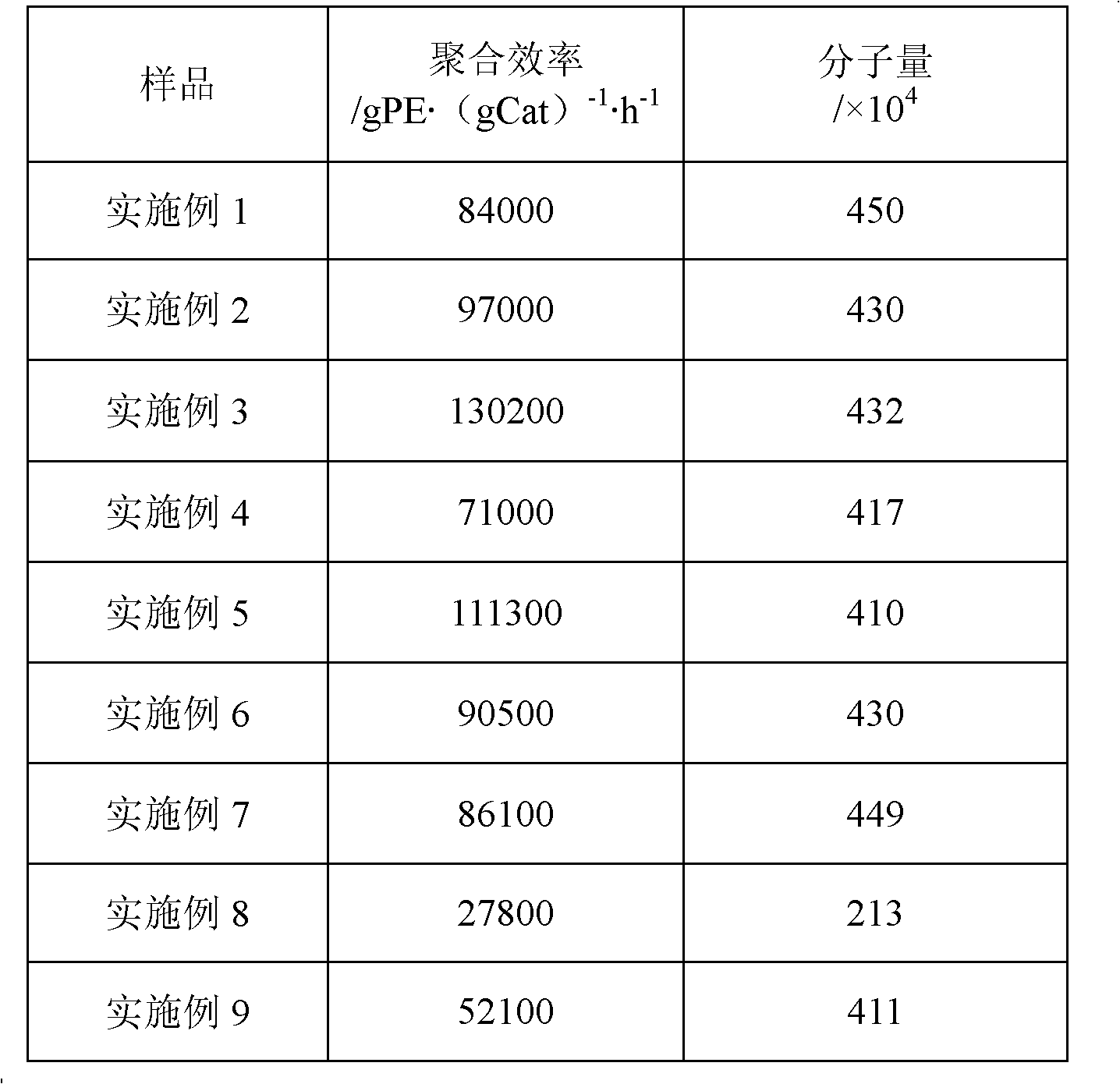

[0055] The preparation method of the catalyst component is the same as in Example 1, but in the process of preparing the catalyst, the ultrasonic treatment time is changed from 1 min to 2 min. The ethylene polymerization test is the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

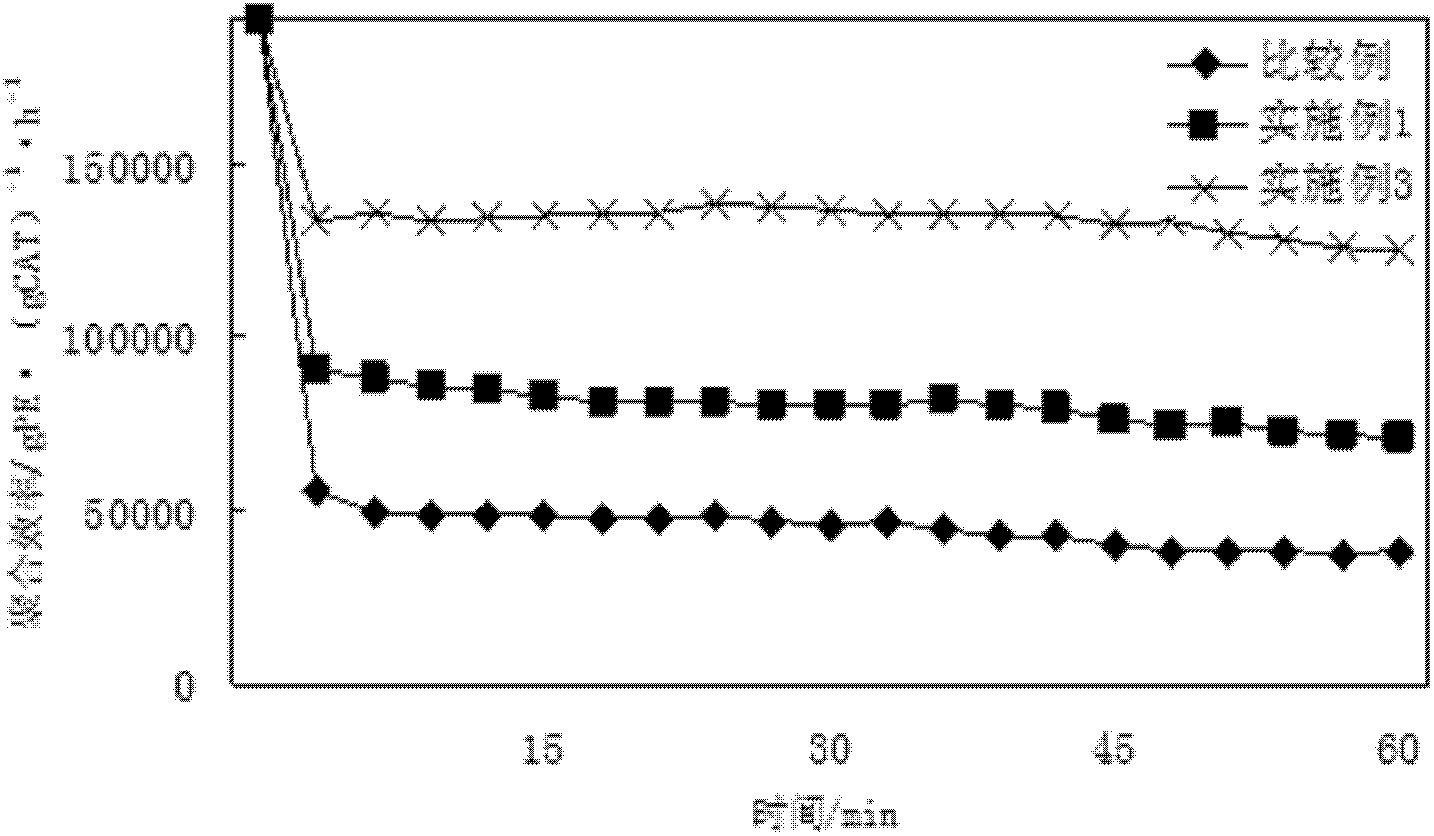

[0057] The preparation method of the catalyst component is the same as in Example 1, but in the process of preparing the catalyst, the ultrasonic treatment time is changed from 1 min to 5 min. Ethylene polymerization test is with embodiment 1, and its result is shown in Table 1, and polymerization kinetics curve is shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com