Double-component polyurethane adhesive, preparation method and application thereof

A two-component polyurethane and adhesive technology, which is applied in polyurea/polyurethane adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of poor sealing properties of polyurethane adhesives, and achieve avoidance of tunnel effect and stability High, good melt fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

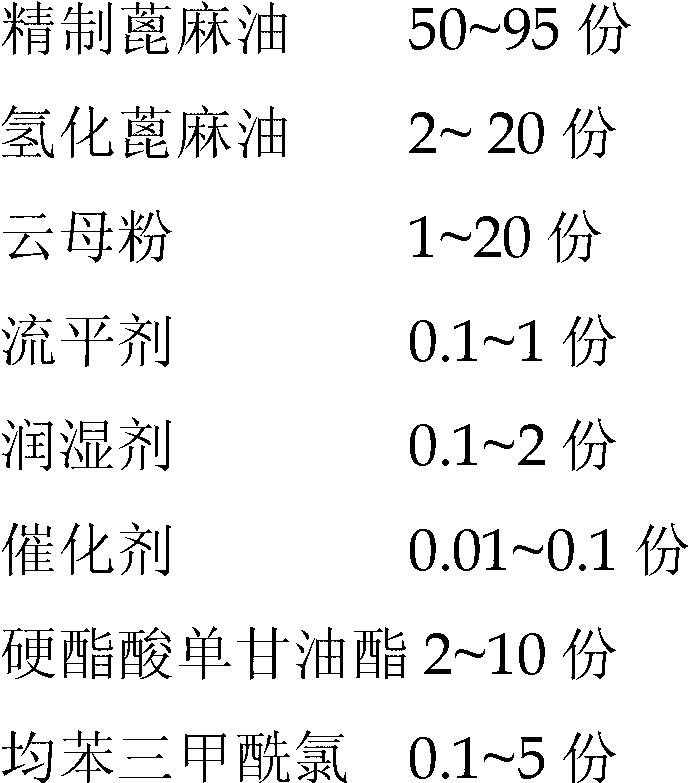

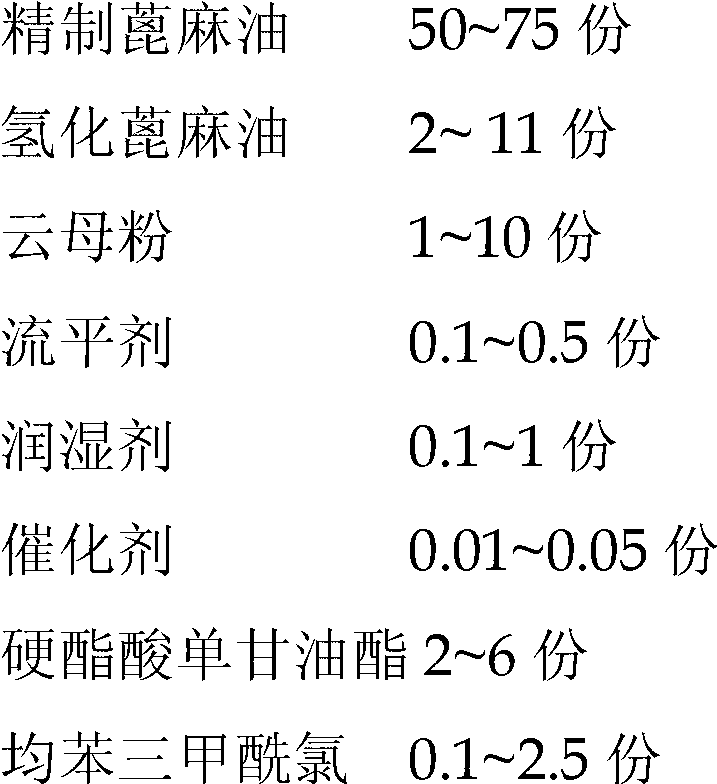

[0043](1) Preparation of component A: Take 50g of refined castor oil, 2g of hydrogenated castor oil, 1g of mica powder, 0.1g of polyether modified silicone, 0.1g of saturated polycarboxylate amine salt, and monoglyceride stearate After mixing 2g and 0.1g of trimesoyl chloride evenly, react at 80°C for 2h, then add 0.01g of organometallic catalyst, and stir to obtain component A;

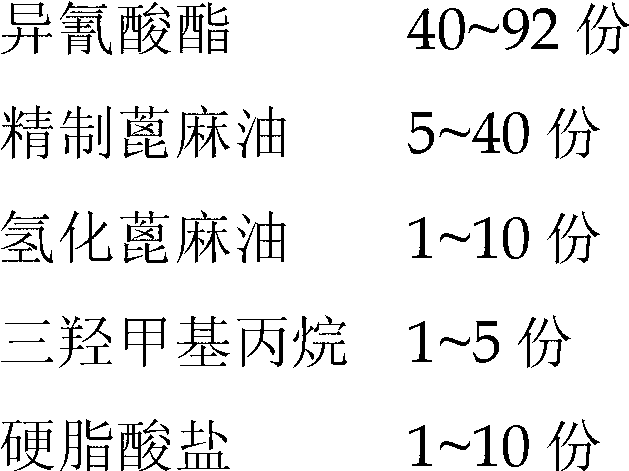

[0044] (2) Preparation of component B: Mix 40g of toluene cyclohexylene diisocyanate, 5g of refined castor oil, 1g of hydrogenated castor oil, 1g of trimethylolpropane and 1g of sodium stearate according to the formula , reacted for 4h to obtain component B;

[0045] (3) Mixing of component A and component B: pack the component A and component B prepared above separately, and mix them at a mass ratio of 1.8:0.8 before use, and then fully stir them evenly.

Embodiment 2

[0047] (1) Preparation of component A: Take 60g of refined castor oil, 5g of hydrogenated castor oil, 5g of mica powder, 0.3g of polyether modified silicone, 0.5g of saturated polycarboxylate amine salt, and monoglyceride stearate After mixing 4g and 2g of trimesoyl chloride evenly, react at 90°C for 1.5h, then add 0.03 parts of organic metals into the catalyst, and stir to obtain component A;

[0048] (2) Preparation of component B: Mix 50g of xylylene diisocyanate, 40g of refined castor oil, 15g of hydrogenated castor oil, 2g of trimethylolpropane and 3g of potassium stearate according to the formula, and then, at 100°C, React 3h to make B component;

[0049] (3) Mixing of component A and component B: Package the component A and component B prepared above separately, mix them at a mass ratio of 1.8:1.2 before use, and then stir well.

Embodiment 3

[0051] (1) Preparation of component A: Take 70g of refined castor oil, 10g of hydrogenated castor oil, 10g of mica powder, 0.5g of fluorine-modified acrylate, 1g of saturated polycarboxylate amine salt, 6g of monoglyceride stearate and After mixing 3 g of benzenetricarboxylic acid chloride evenly, react at 90°C for 1.5 h, then add 0.05 g of amine catalyst, and stir to obtain component A;

[0052] (2) Preparation of component B: Mix 70g of hexamethylene diisocyanate, 20g of refined castor oil, 25g of hydrogenated castor oil, 3g of trimethylolpropane and 5g of calcium stearate according to the formula, and react at 120°C for 2h Prepare B component;

[0053] (3) Mixing of component A and component B: Package the component A and component B prepared above separately, and mix them at a mass ratio of 1:1 before use and then stir well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com