A high-resolution biosensor

A biosensor, high-resolution technology, applied in the field of sensors, can solve the problems of complex device structure, and achieve the effects of simple preparation method, firm structure, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Embodiment 1: synthesis and transfer graphene film

[0036] Graphene film was synthesized on Cu by chemical vapor deposition method: the surface of Cu sheet with a thickness of 25 μm was polished and cleaned, and it was placed in an ultra-high vacuum (1×10 -8 torr), then in Ar / H 2 In atmosphere (~20 vol% H 2 ) for about 110 minutes at 750 ºC, then raise the temperature to ~950 ºC for 30 minutes; turn off the Ar / H 2 , while the modified CH 4 To synthesize the graphene film, the growth time is 5 minutes, thus the graphene film is synthesized.

[0037] After the graphene film is synthesized, spin-coat 500 nm Polymethylmethacrylate (PMMA) layer on the synthesized graphene film, the graphene film / Cu that will be coated with PMMA is placed in ferric nitrate solution and Cu is corroded, PMMA / graphene The film was separated from the Cu substrate, resulting in a PMMA / graphene film. Then, the PMMA / graphene film was transferred to the Al 2 o 3 (100 nm) / Si(550 µm) in Al 2 ...

Embodiment 2

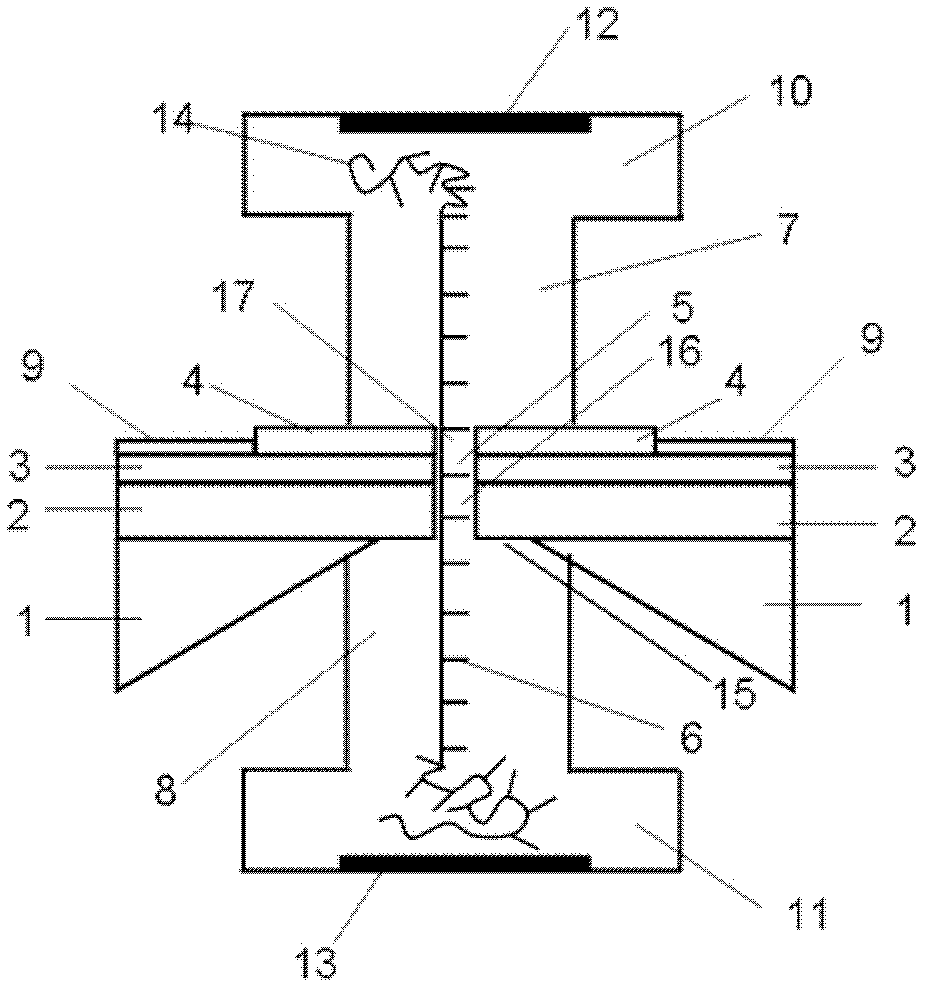

[0038] Embodiment 2: Graphene is as the biosensor of sensitive functional layer

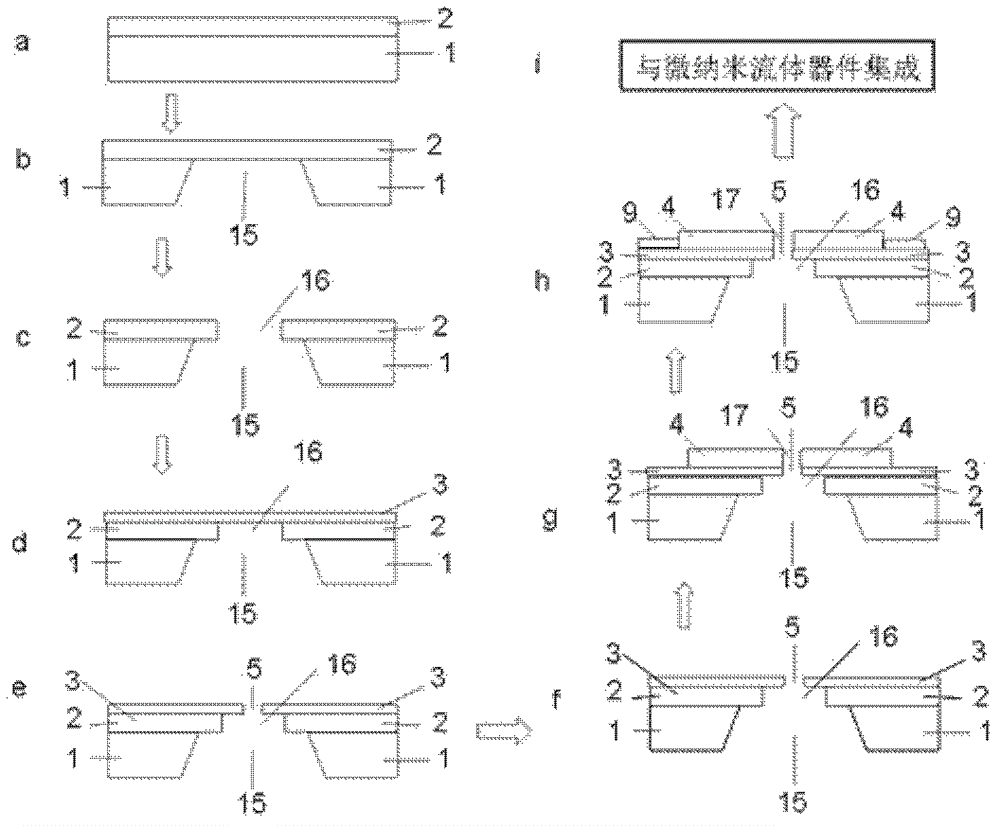

[0039] Such as figure 2 Shown: 100 nm Al prepared on a 550 µm thick Si substrate1 2 o 3 The first insulating layer 2 ( figure 2 a).

[0040] Using photolithography and mask technology, and etching the silicon substrate with KOH solution to prepare a square opening 15 ( figure 2 b).

[0041] Using photolithography and mask technology, and using buffered HF solution to etch the Al on the square opening of the silicon substrate 2 o 3 Thus a hole 16 with a diameter of 10 mm ( figure 2 c).

[0042] Transfer the prepared graphene film to Al 2 o 3 (100 nm) / Si(550 µm) in Al 2 o 3 As the sensitive functional layer 3 on the first insulating layer, the graphene film covers Al 2 o 3 hole 16 ( image 3 ).

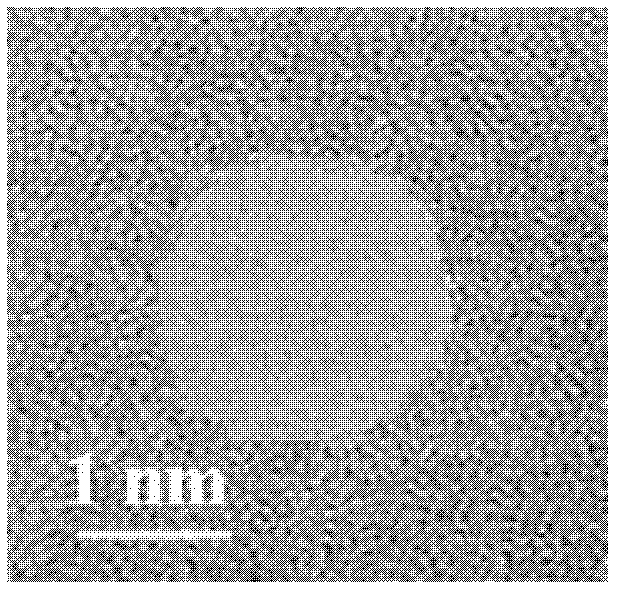

[0043] Fabrication of graphene nanopores using an electron beam from a transmission electron microscope (JEOL 2010F) 5: Adjust the magnification of the transmission electron microscope...

Embodiment 3

[0048] Example 3: MoS 2 Biosensors as sensitive functional layers

[0049] Such as Figure 4 Shown: 50 nm SiO fabricated sequentially on a 600 µm thick monocrystalline Si substrate 1 2 and 30 nm Si 3 N 4 Composite insulating layer 2 ( Figure 4 a).

[0050] Using photolithography technology, and using KOH solution and buffered HF solution to etch the silicon substrate and SiO 2 And prepare a square opening 15 ( Figure 4 b).

[0051] E-beam etching with SF 6 Plasma Reactive Etching Technology in Si 3 N 4 A hole 16 ( Figure 4 c).

[0052] Bilayer MoS produced by mechanical exfoliation 2 Thin films transferred to Si 3 N 4 (30nm) / SiO 2 (50 nm) / Si of Si 3 N 4 As a sub-nanometer functional layer3, MoS 2 Thin film covered silicon nitride membrane holes 16 ( Figure 4 d).

[0053] Preparation of MoS using electron beam from transmission electron microscopy (JEOL 2010F) 2 Nanopore 5: Adjust the magnification of the transmission electron microscope to about 800...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com