Rhodococcus erythropolis capable of converting quininone into (S)-3-quinuclidinol and conversion method

A technology of Rhodococcus erythropolis and quinine alcohol, which is applied in the field of bioengineering to achieve the effects of easy cultivation, high yield and stable catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Screening and identification of strains

[0051] 1.1 Medium

[0052] Inorganic salt medium: K 2 HPO 4 ·3H 2 O 1.0g, Na 2 HPO 4 ·3H 2 O 1.0g, (NH 4 ) 2 HPO 4 2.0g, NaNO 3 2.0g, MgSO 4 ·7H 2 O 0.2g, CaCl 2 2H 2 O 10mg, FeSO 4 ·7H 2 O 1.0mg, ZnSO 4 0.1mg, distilled water 1000mL.

[0053] A certain concentration of quinine hydrochloride was added to the inorganic salt medium to prepare the corresponding enrichment medium.

[0054] 1.2 Isolation and purification of strains

[0055] Put 5 g of the collected sample into a 250 mL shaker flask containing 50 mL of sterile water, add glass beads, oscillate on a shaking table at 250 r / min for 2 hours, and let it stand for 3-5 minutes. After the soil particles settle, take out 2 mL of the supernatant and add Into 50mL liquid enrichment medium (containing quinine hydrochloride 5g / L), 30°C, 200r / min shaker culture for 3-4 days, transfer to the next batch of enrichment medium according to 2% inoculum...

Embodiment 2

[0059] Embodiment 2: Preliminary optimization of fermentation conditions of Rhodococcus erythropolis WY1406

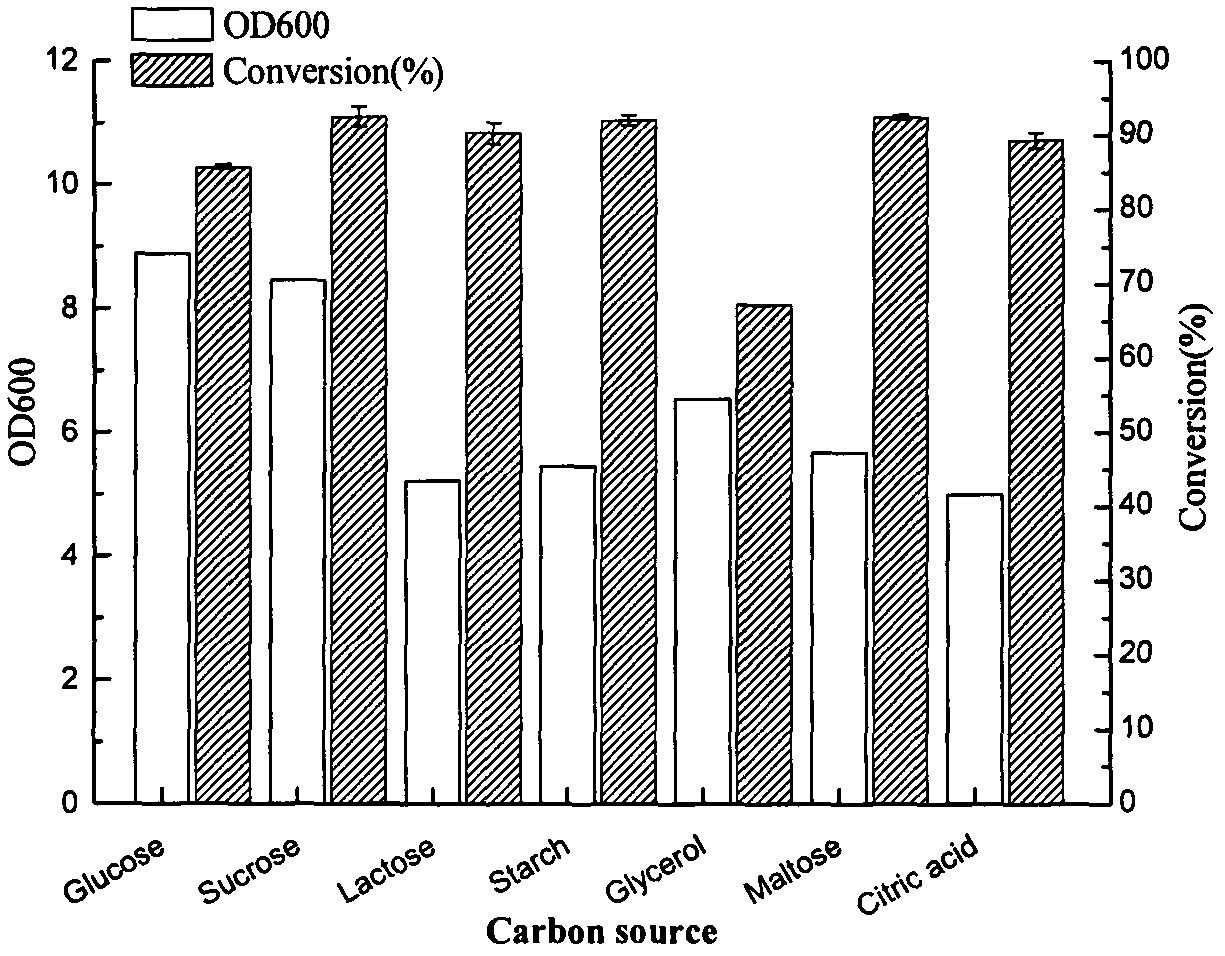

[0060] 1 Single factor experiment of carbon source

[0061] The addition amount of different carbon sources in the fermentation medium was 15g / L.

[0062] Table 1, the reaction of different carbon source fermentation bacteria transforming quinine into (S)-3-quinine alcohol

[0063]

[0064] From image 3 It can be seen from the results that when glucose and sucrose were used as carbon sources, the cell growth was the best. Among them, when sucrose and maltose were used as carbon sources, the conversion effect of the bacteria to quinine was the best. Considering the growth of bacteria and the conversion of substrates, sucrose is the optimal carbon source.

[0065] 2 Single factor experiment of nitrogen source

[0066] The addition amount of different nitrogen sources in the fermentation medium was 10g / L.

[0067] Table 2, the reaction of different nitrogen sour...

Embodiment 3

[0070] Embodiment 3: strain conversion quinine ketone is the conversion method of (S)-3-quinine alcohol

[0071] 1 Preparation of seed solution

[0072] Inoculate Rhodococcus erythropolis WY1406 into the sterilized liquid medium, culture at 30° C. for 24 h, and shaker speed 200 r / min to obtain seed liquid.

[0073] The liquid medium is configured according to the following proportions: glucose 10g / L, peptone 5g / L, yeast extract 5g / L, sodium chloride 1g / L, pH 7.0.

[0074] 2 Fermentation expansion culture

[0075] The seed liquid obtained in step 1 is inoculated into the fermentation medium according to the inoculation amount of 1% to carry out fermentation culture. Culture conditions: 30°C, shaker speed 200r / min, fermentation time 24h, the fermentation broth of Rhodococcus erythropolis is obtained.

[0076] The composition of the fermentation medium is: sucrose 15g / L, yeast extract 7g / L, peptone 3g / L, potassium dihydrogen phosphate 1g / L, dipotassium hydrogen phosphate 1g / L,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com