Spherical layered nickel-cobalt-manganese oxide lithium-ion battery cathode material

A nickel-cobalt-manganese-lithium, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of no improvement in material safety, deterioration of electrode performance, weakening of technical advantages, etc., to improve safety performance and Effects of cycle performance, good rate capability and cycle performance, excellent filling and flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

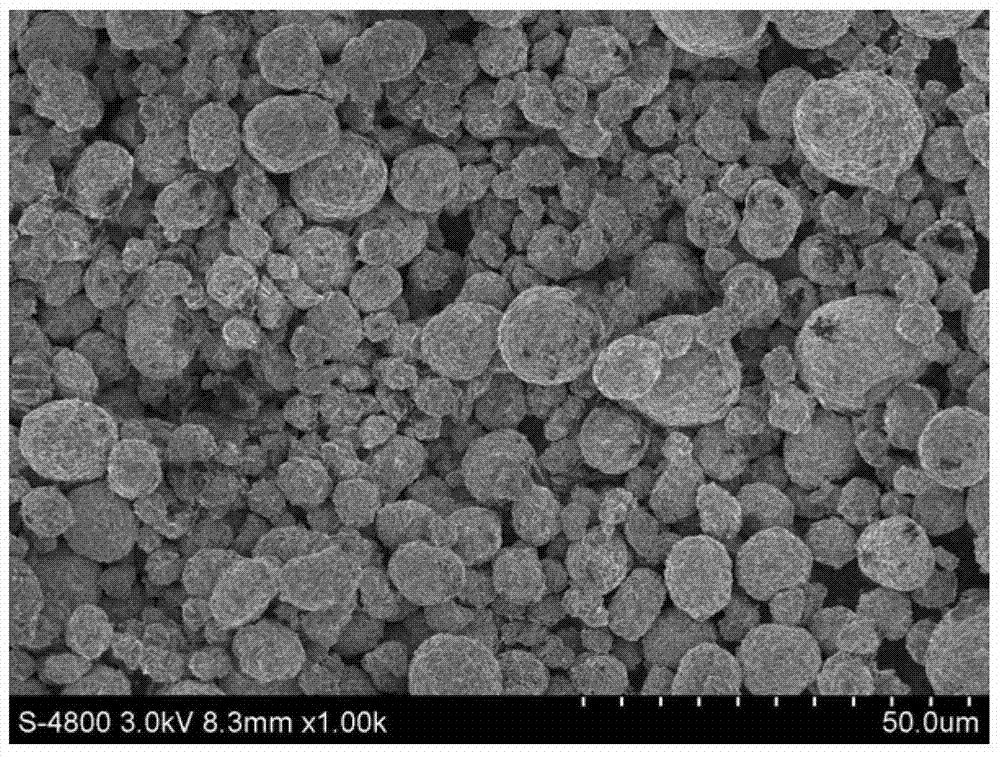

[0032] Step 1: Preparation of dense and small particle spherical LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Cathode material

[0033] ⑴ Prepare the solution

[0034] Weigh nickel sulfate, cobalt sulfate, and manganese sulfate with a composite stoichiometric ratio of 1:1:1, and prepare a nickel-cobalt-manganese sulfate mixed solution, which is recorded as solution a; sodium hydroxide is used as a precipitating agent, and ammonia water is used as a complexing agent , mix the precipitant solution and the complexing agent solution according to the ammonia-alkali molar ratio of 0.37, and record it as solution b;

[0035] (2) The reaction process of the two solutions

[0036] The two solutions of a and b are pumped in parallel and protected by a nitrogen atmosphere, with a volume of 3m 3 In a stainless steel reaction kettle, at 50°C, stirring at a speed of 300r / mim, using an online pH value control system to keep the reaction pH at about 11.8±0.05, and reacting at a constant temperature for 3...

Embodiment 2

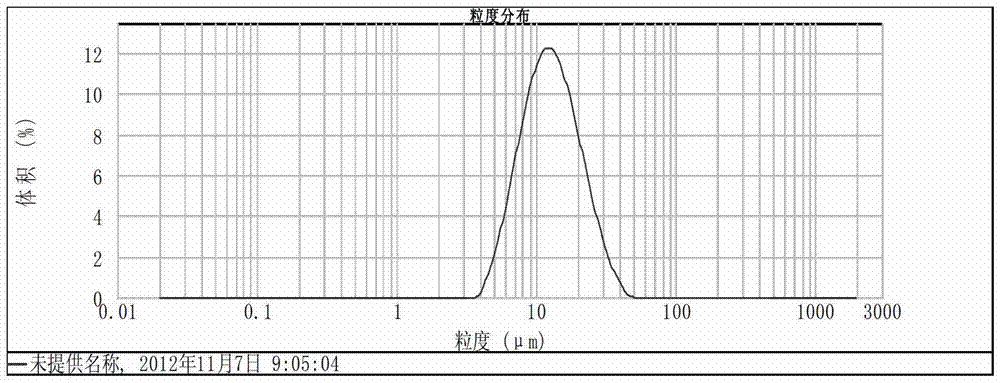

[0053] Be 1:10 by mass ratio, the compact small particle spherical LiNi prepared in step 1 in embodiment 1 1 / 3 co 1 / 3 mn 1 / 3 o 2 and the dense large particle spherical LiNi prepared in step 2 1 / 3 co 1 / 3 mn 1 / 3 o 2 Put it into a dry blender and mix it at a speed of 400r / min for 15 minutes to make the spherical layered nickel-cobalt-manganese oxide lithium-ion battery cathode material of the present invention. The particle size distribution of the material is between 7 and 26 μm, and the tap density is 2.96g / cm 3 , compacted density 3.79g / cm 3 , the energy density of a single pole piece at 0.5C is 605mAh / cm 3 . Through a small amount of compounding and mixing, the compaction density and tap density of the positive electrode material are improved compared with a single material, and the energy density is better than that of a single lithium cobaltate positive electrode material and LiNi prepared by other methods. 1 / 3 co 1 / 3 mn 1 / 3 o 2 Cathode material.

Embodiment 3

[0055] Be 3:10 by mass ratio, the compact small particle spherical LiNi prepared in step 1 in embodiment 1 1 / 3 co 1 / 3 mn 1 / 3 o 2 and the dense large particle spherical LiNi prepared in step 2 1 / 3 co 1 / 3 mn 1 / 3 o 2 Put it into a dry blender, mix at a speed of 400r / min for 15 minutes, and then make a spherical layered nickel-cobalt-manganese-lithium-ion battery positive electrode material. The particle size distribution of the material is between 4 and 21 microns, and the tap density is 2.83g / cm 3 , compacted density 3.67g / cm 3 , the energy density of a single pole piece at 0.5C is 591mAh / cm 3 . Through compounding and mixing, the compaction density of the positive electrode material is improved compared with that of a single material, and the energy density is higher than that of a single lithium cobalt oxide positive electrode material and LiNi prepared by other methods. 1 / 3 co 1 / 3 mn 1 / 3 o 2 Cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com