Carbon-coated doping modified lithium titanate and preparation method thereof

A kind of lithium titanate and carbon coating technology, applied in the field of electrochemical power source material preparation, can solve the problems of unsatisfactory high rate performance, difficult to control particle size, poor electronic conductivity, etc., to improve intrinsic electronic conductivity, Effect of reduced electrode polarization and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

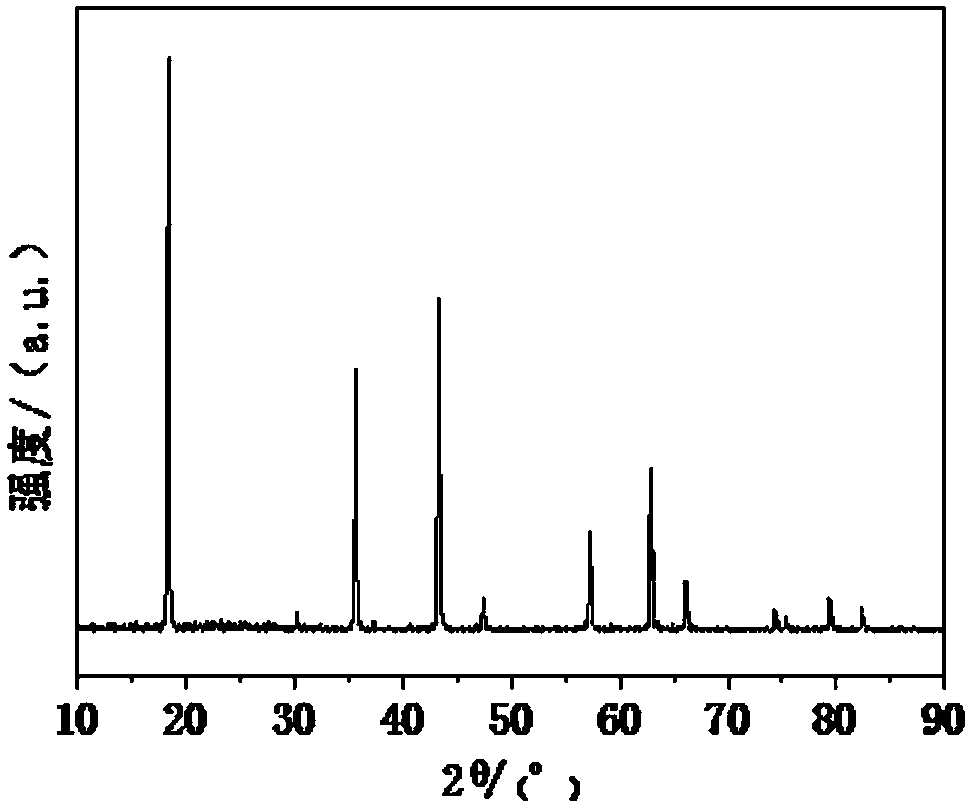

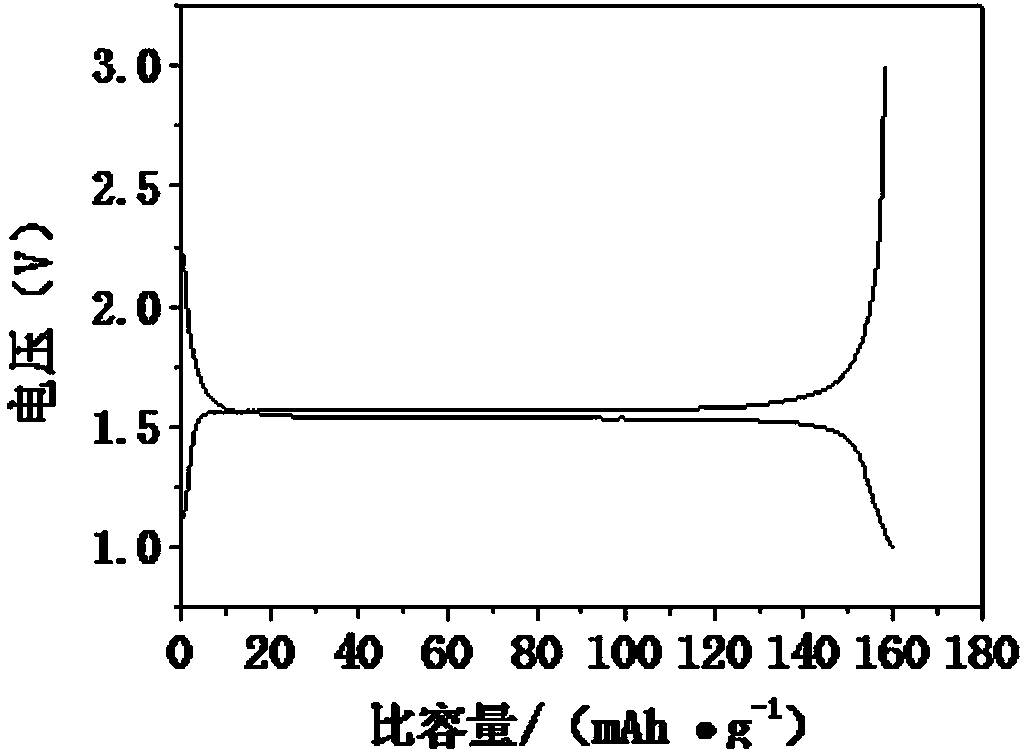

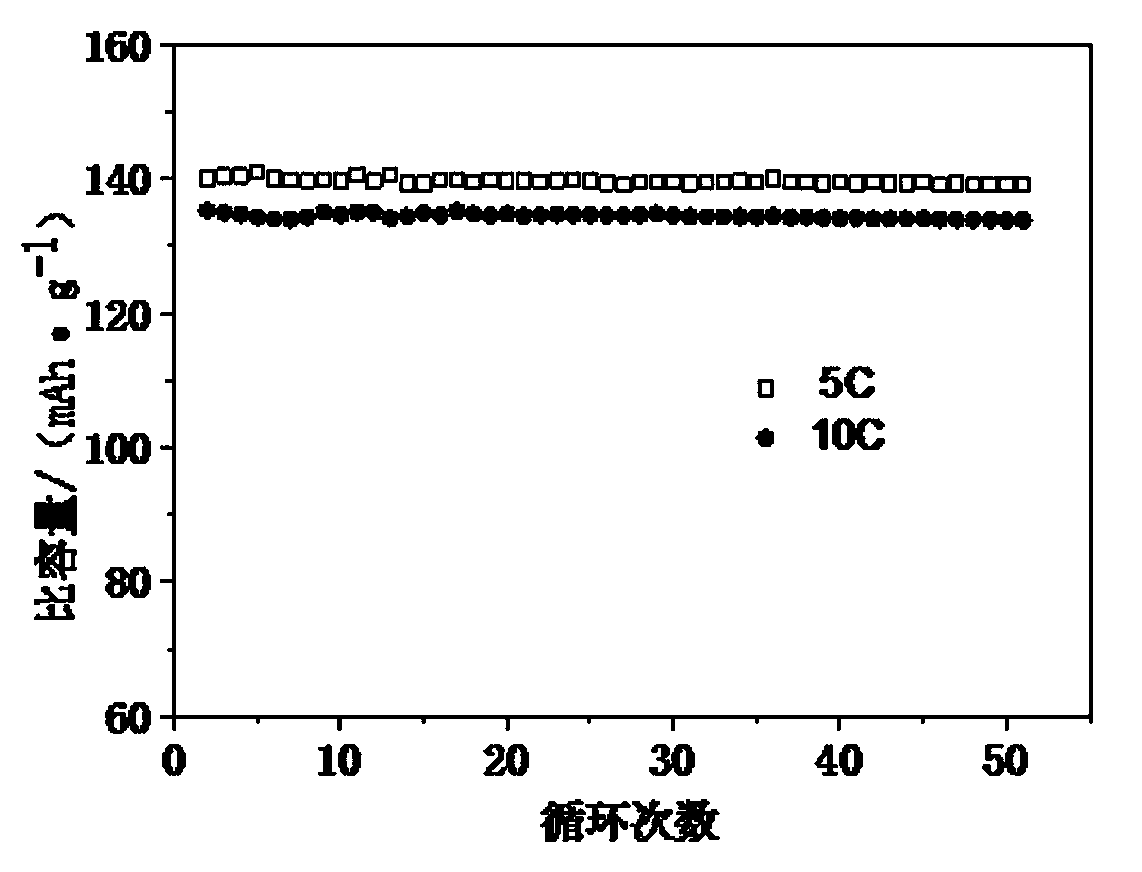

[0026] Ultrasonic dispersion of micron-sized anatase titanium dioxide, sucrose and nano-sized iron powder in absolute ethanol at a mass ratio of 15:5:2 and magnetically stirred for 0.5 hours to obtain a suspension, which was dried at 80°C for 2 hours to obtain a paste Using argon as a protective atmosphere, heat-treat the paste at 500°C for 2 hours to obtain carbon-coated titanium dioxide, then soak carbon-coated titanium dioxide with 5mol / L sulfuric acid for 1 hour, wash, dry and grind to obtain coated titanium dioxide. The coating has carbon-coated titanium dioxide with tiny pores; then weigh lithium hydroxide, carbon-coated titanium dioxide, magnesium carbonate and aluminum oxide according to the atomic molar ratio of lithium, titanium, magnesium and aluminum 3.74:4.8:0.3:0.2, and the above The mixture was fully mixed for 16 hours, then calcined under a nitrogen atmosphere, kept at 600°C for 6 hours, and then kept at 800°C for 4 hours; cooled to room temperature with the fur...

Embodiment 2

[0028] Nanoscale anatase titanium dioxide, starch and nanoscale aluminum powder are ultrasonically dispersed in absolute ethanol in a mass ratio of 20:5:4, and magnetically stirred for 2 hours to obtain a suspension, which is dried at 80°C for 2 hours to obtain The paste, using argon as a protective atmosphere, heat-treated the paste at 550°C for 3 hours to obtain carbon-coated titanium dioxide, then soaked carbon-coated titanium dioxide in 5mol / L hydrochloric acid for 0.5 hours, washed, dried and ground The cladding layer has carbon-coated titanium dioxide with tiny pores; then lithium carbonate, carbon-coated titanium dioxide, magnesium carbonate and aluminum hydroxide are weighed according to the atomic molar ratio of lithium, titanium, magnesium and aluminum 3.94:4.85:0.1:0.15, and The above mixture was fully mixed for 24 hours, then calcined under an argon atmosphere, kept at 600°C for 8 hours, and then kept at 850°C for 2 hours; cooled to room temperature with the furnace...

Embodiment 3

[0030] Ultrasonic dispersion of micron-sized anatase titanium dioxide, glucose and micron-sized iron powder in absolute ethanol in a mass ratio of 20:10:4, and magnetic stirring for 3 hours to obtain a suspension, which was dried at 80°C for 2 hours to obtain The paste, using nitrogen as a protective atmosphere, heat-treated the paste at 600°C for 1 hour to obtain carbon-coated titanium dioxide, then soaked carbon-coated titanium dioxide in 5mol / L sulfuric acid for 3 hours, washed, dried and ground to obtain coated titanium dioxide. The coating has carbon-coated titanium dioxide with tiny pores; then, lithium hydroxide, carbon-coated titanium dioxide, magnesium acetate and aluminum oxide are weighed according to the atomic molar ratio of lithium, titanium, magnesium and aluminum 3.99:4.98:0.05:0.02, and the above The mixture was fully mixed for 18 hours, then calcined under a nitrogen atmosphere, kept at 650°C for 12 hours, and then kept at 800°C for 6 hours; cooled to room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com