A kind of preparation method of organically modified attapulgite adsorbent

A technology of attapulgite and attapulgite powder is applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effects of simple and easy modification route, low energy consumption and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Pulverize attapulgite clay raw ore with attapulgite content ≥ 98wt%, and pass through a 200-mesh sieve to obtain attapulgite powder, take 2.5g attapulgite powder and 5g cellulose, mix in 72ml distilled water, and then add ferrous ammonium sulfate 2.8g, ultrasonically dispersed to obtain a mixed solution, and the pH of the mixed solution was 5 at this time;

[0023] Transfer the mixed solution to a polytetrafluoroethylene hydrothermal tank, keep the filling rate at 75%, and carbonize for 12 hours at a reaction temperature of 250°C; after the reaction is completed, it is naturally cooled to room temperature, centrifuged and washed alternately with water and ethanol. The black product obtained by drying at 60°C is the organically modified attapulgite.

[0024] SEM and infrared spectroscopic analysis showed that the surface of attapulgite supported nano-carbons containing organic functional groups such as C-H.

[0025] Take the phenol solution with an initial concentration...

Embodiment 2

[0027] Pulverize attapulgite clay raw ore with attapulgite content ≥ 98wt%, and pass through a 200-mesh sieve to obtain attapulgite powder, take 2.5g attapulgite powder and 5g cellulose, mix in 72ml distilled water, and then add ferrous ammonium sulfate 2.8g, ultrasonically dispersed to obtain a mixed solution, and the pH of the mixed solution was 5 at this time;

[0028] Transfer the mixed solution to a polytetrafluoroethylene hydrothermal tank, keep the filling rate at 80%, and carbonize for 12 hours at a reaction temperature of 240°C; after the reaction is completed, it is naturally cooled to room temperature, centrifuged and washed alternately with water and ethanol. The black product obtained by drying at 60°C is the organically modified attapulgite.

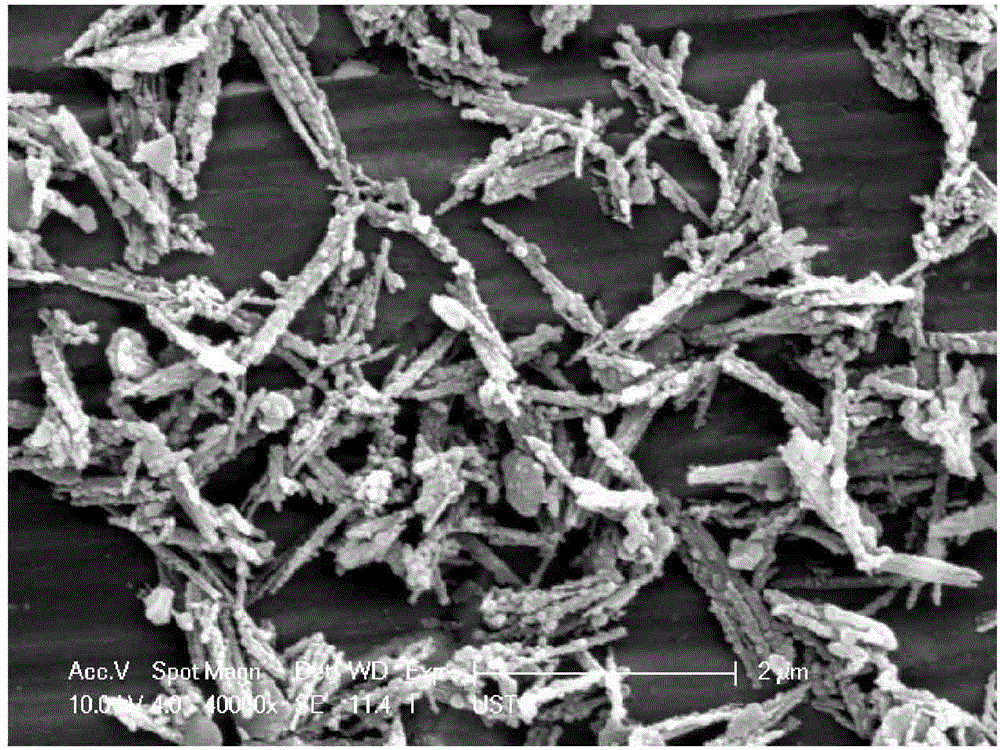

[0029] Infrared analysis shows that organically modified attapulgite contains organic functional groups such as C-H; SEM analysis shows that amorphous carbon is loaded on attapulgite (see figure 1 ).

[0030] Take the phe...

Embodiment 3

[0032] Pulverize attapulgite clay raw ore with attapulgite content ≥ 98wt%, and pass through a 200-mesh sieve to obtain attapulgite powder, take 2.5g attapulgite powder and 10g cellulose, mix in 72ml distilled water, and then add ferrous ammonium sulfate 3.0g, ultrasonically dispersed to obtain a mixed solution, and the pH of the mixed solution was 5 at this time;

[0033] The mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, the filling rate was kept at 80%, the reaction temperature was 250°C, and carbonization was carried out for 48 hours; after the reaction was completed, it was naturally cooled to room temperature, centrifuged and washed alternately with water and ethanol, and then placed in The black product obtained by drying at 60°C is the organically modified attapulgite.

[0034] Infrared analysis shows that the organically modified attapulgite contains organic functional groups such as C-H. SEM characterization revealed that amorphous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com