Weak bitter corn oligopeptide with high content of alanine and leucine and preparation method thereof

A technology of corn oligopeptide and leucine, which is applied to the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of difficult industrial implementation, difficult to accept, and low product purity, and achieve easy industrial realization, Improve the product yield and the effect of high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

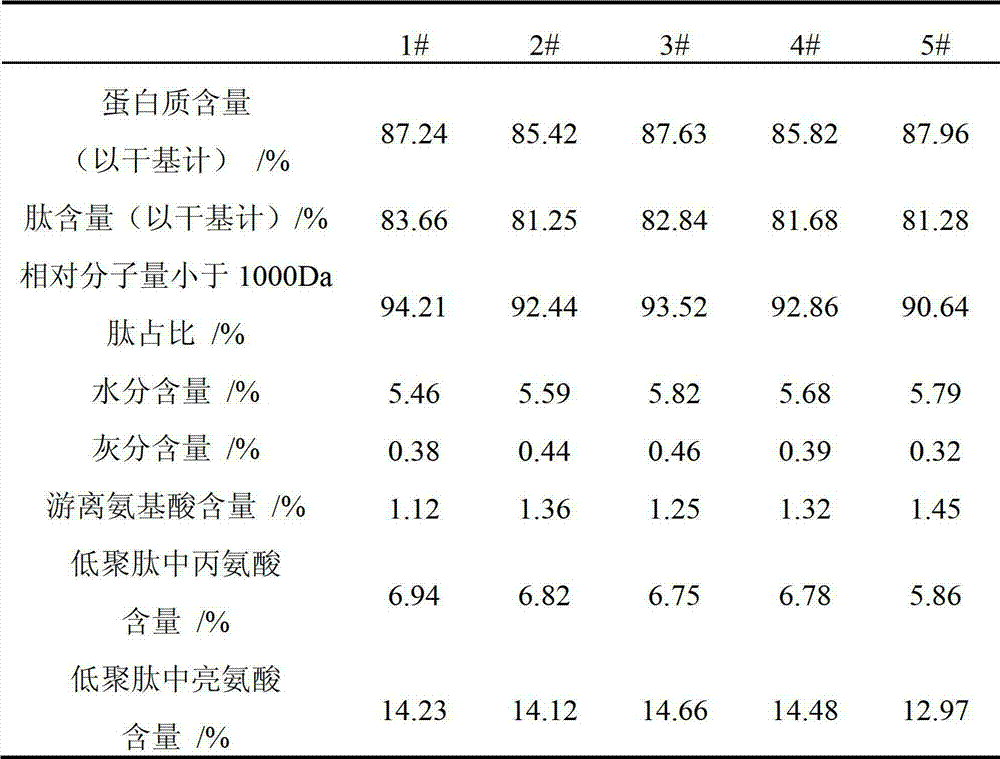

Examples

Embodiment 1

[0040] (1) Dispersion and hydration of corn gluten powder: crush corn gluten powder (protein content ≥ 60%, purchased from Shanxi Wang Group) to 80 mesh, and prepare corn gluten powder with deionized water to a mass percentage of 10% corn gluten solution, disperse and hydrate the corn gluten powder for 20 minutes with a mixer at a speed of 2000 rpm;

[0041] (2) Gelatinization, degreasing, and starch removal: use a molar concentration of 3mol.L -1 Sodium hydroxide solution to adjust the pH of the corn gluten powder solution to 6.0, heat it to 82°C, and keep it for 40 minutes, so that the molecular structure of the corn gluten is fully expanded, and the starch in it is fully gelatinized; add 0.5 % α-high temperature amylase (SUKAMy-Hi LQ20, SUKAMy-Hi LQ20, Sukehan Bioengineering Co., Ltd.), hydrolyzed at 36rpm, 82°C for 45min, after the end of the enzymolysis, the enzymatic solution was kept at 95°C for 15min, and the α-blunt Inactivate the activity of high-temperature amylase...

Embodiment 2

[0046] (1) Dispersion and hydration of corn gluten powder: crush corn gluten powder (protein content ≥ 60%, purchased from Shanxi Wang Group) to 80 mesh, and prepare corn gluten powder with deionized water to a mass percentage of 20% corn gluten solution, disperse and hydrate the corn gluten powder with a mixer at a speed of 3000 rpm for 10 minutes;

[0047] (2) Gelatinization, degreasing, and starch removal: use a molar concentration of 5mol.L -1 Adjust the pH of the corn gluten powder solution to 7.0 with a sodium hydroxide solution, heat it to 80°C, and keep it for 60 minutes to fully expand the molecular structure of the corn gluten and fully gelatinize the starch in it; add 1 % α-high temperature amylase (SUKAMy-Hi LQ20, SUKAMy-Hi LQ20, Sukehan Bioengineering Co., Ltd.), hydrolyzed at 36rpm, 80°C for 60min, after the end of the enzymolysis, the enzymatic solution was kept at 95°C for 20min, and the α-blunt Inactivate the activity of high-temperature amylase, then cool do...

Embodiment 3

[0052] (1) Dispersion and hydration of corn gluten powder: crush corn gluten powder (protein content ≥ 60%, purchased from Shanxi Wang Group) to 80 mesh, and prepare corn gluten powder with deionized water to a mass percentage of 5% corn gluten solution, disperse and hydrate the corn gluten powder with a mixer at a speed of 2500 rpm for 15 minutes;

[0053] (2) Gelatinization, degreasing, and starch removal: use a molar concentration of 1mol.L -1 Sodium hydroxide solution to adjust the pH of the corn gluten powder solution to 5.0, heat it to 85°C, and keep it for 20 minutes, so that the molecular structure of the corn gluten is fully expanded, and the starch in it is fully gelatinized; add 0.1 % α-high temperature amylase (SUKAMy-Hi LQ20, SUKAMy-Hi LQ20, Sukehan Bioengineering Co., Ltd.), hydrolyzed at 36rpm and 85°C for 30min, after the end of the enzymolysis, the enzymatic solution was kept at 100°C for 10min, and the α-blunt Inactivate the activity of high-temperature amyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com