Flame-retardant glass fiber-reinforced HDPE/PA6 alloy material with high CTI value and high GWIT value

A technology of alloy materials and glass fiber, which is applied in the field of HDPE/PA6 alloy materials, can solve the problems of unsuitable electricity environment, low CTI value and GWIT value, etc., and achieve improved oxidation resistance, improved processing fluidity, and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

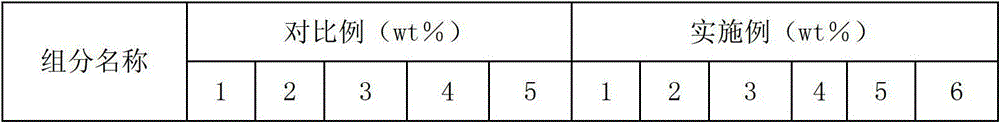

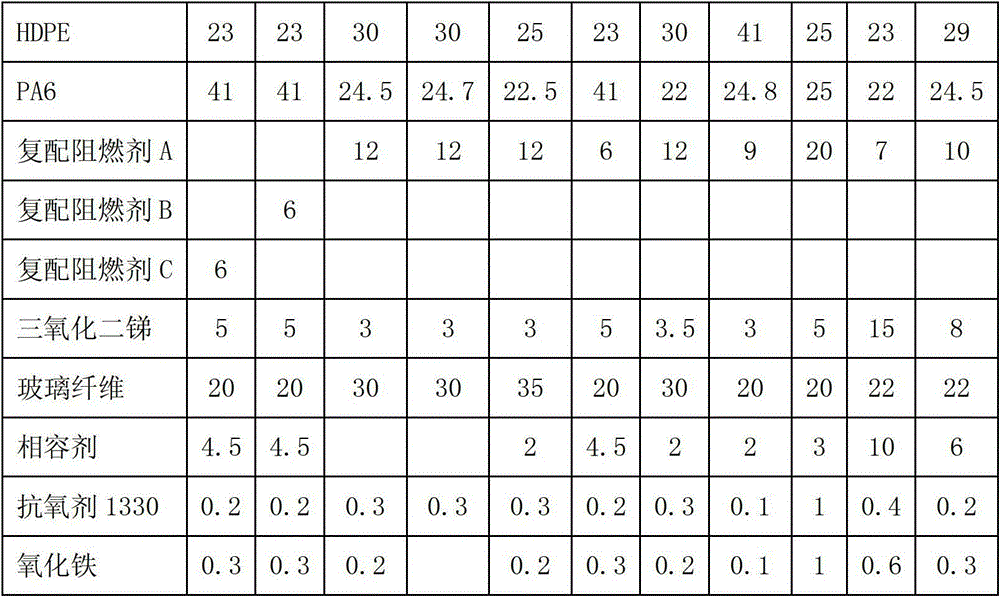

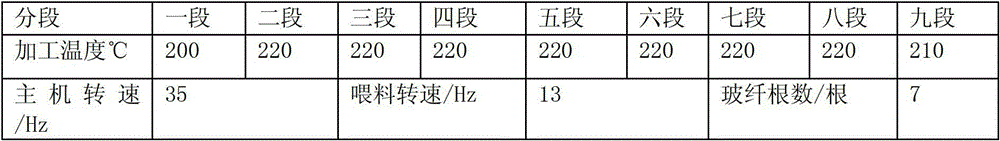

[0028] The high CTI value, high GWIT value flame-retardant glass fiber reinforced HDPE / PA6 alloy material of Examples 1-6, each component contained is shown in Table 1, wherein, HDPE is commercially available high-density polyethylene, PA6 is intrinsic viscosity It is commercially available polyamide 6 of 2.8dl / g, and the glass fiber is an alkali-free glass fiber treated with a silane coupling agent on the surface (specifically: adding the alkali-free glass fiber into the silane coupling agent to make its surface through silane coupling agent treatment), the compatibilizer is commercially available maleic anhydride grafted HDPE, the compound flame retardant A is a mixture of three components, and its mass percentage is BPS (brominated polystyrene): 50%, hypophosphorous acid Magnesium: 25%, talcum powder: 25%, compound flame retardant B is BPS, GF (non-reactive flame retardant containing nitrogen and phosphorus) and antimony trioxide at a mass ratio of 2:1:1 Compound system, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com