Biodiesel preparation method

A biodiesel and microorganism technology, applied in the fields of biofuel, petroleum industry, fuel, etc., can solve the problems of affecting the conversion rate of transesterification, unfavorable transesterification reaction, complicated treatment process, etc., and achieve low acid value and short reaction time. , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

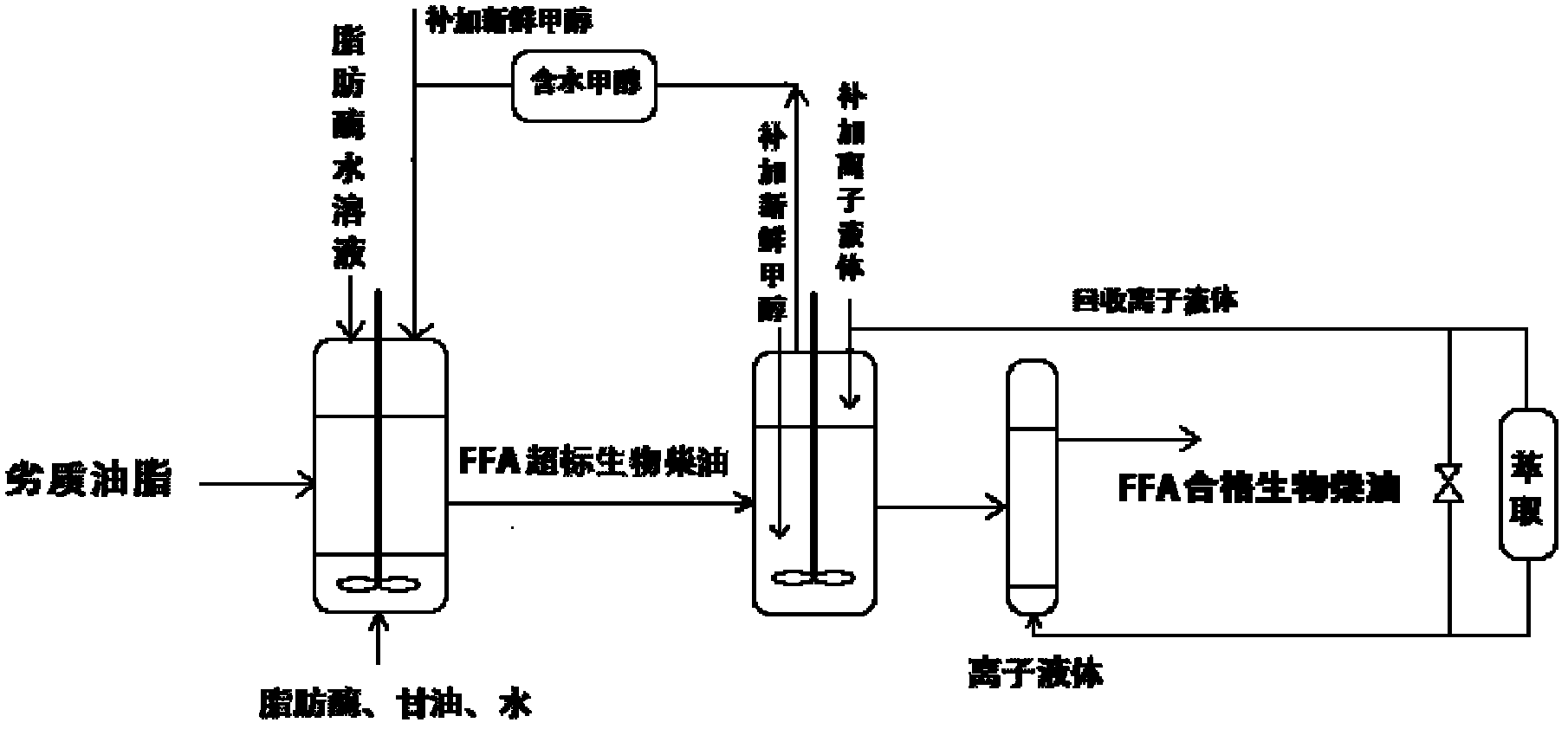

[0022] According to the present invention, the preparation method of the biodiesel comprises the following steps:

[0023] (1) in the presence of lipase aqueous solution, raw material oil and fat are reacted with monohydric alcohol, and the condition of reaction comprises that the mol ratio of monohydric alcohol and according to raw material oil and fat hydrolyzate fatty acid is 1-3: 1; In every gram of raw material oil, The enzyme amount of lipase in the lipase aqueous solution is 100-500U, and the specific activity of lipase in the lipase aqueous solution is 200-1000U / ml; the reaction temperature is 20-60 DEG C, and the reaction time is 4-20 Hour;

[0024] (2) Separating the upper oil phase and the aqueous phase containing lipase and glycerol from the product obtained in step (1).

[0025] According to the present invention, in order to avoid the problem that when the immobilized enzyme catalyst is used, the less water content of the system will make the monohydric alcohol ...

Embodiment 1

[0070] This example is used to illustrate the preparation method of the biodiesel provided by the present invention.

[0071] (1) Acidified oil (saponification by-products in the process of edible oil refining, see "Modern Engineering", 2008, 28 Supplement (2), 73-78) for composition and main properties) 282g (according to GB / T5530-2005 specified molecular weight according to oil Acid, regarded as 1 mole), methanol 64g (methanol and acidified oil molar ratio of 2:1) and lipase aqueous solution mixed reaction, wherein, methanol was divided into 3 parts, respectively at the 0th hour, the 3rd hour and the lipase solution. In the 6th hour, it was added to the reaction system. Described lipase aqueous solution is 1,3 position-specific lipase A aqueous solution (derived from dry root enzyme (Rhizopus niveus), commercially available from Amano Enzyme company's product F3G, the specific activity of lipase in the lipase A aqueous solution is 600U / ml) 100ml and an aqueous solution of ...

Embodiment 2

[0075] This example is used to illustrate the preparation method of the biodiesel provided by the present invention.

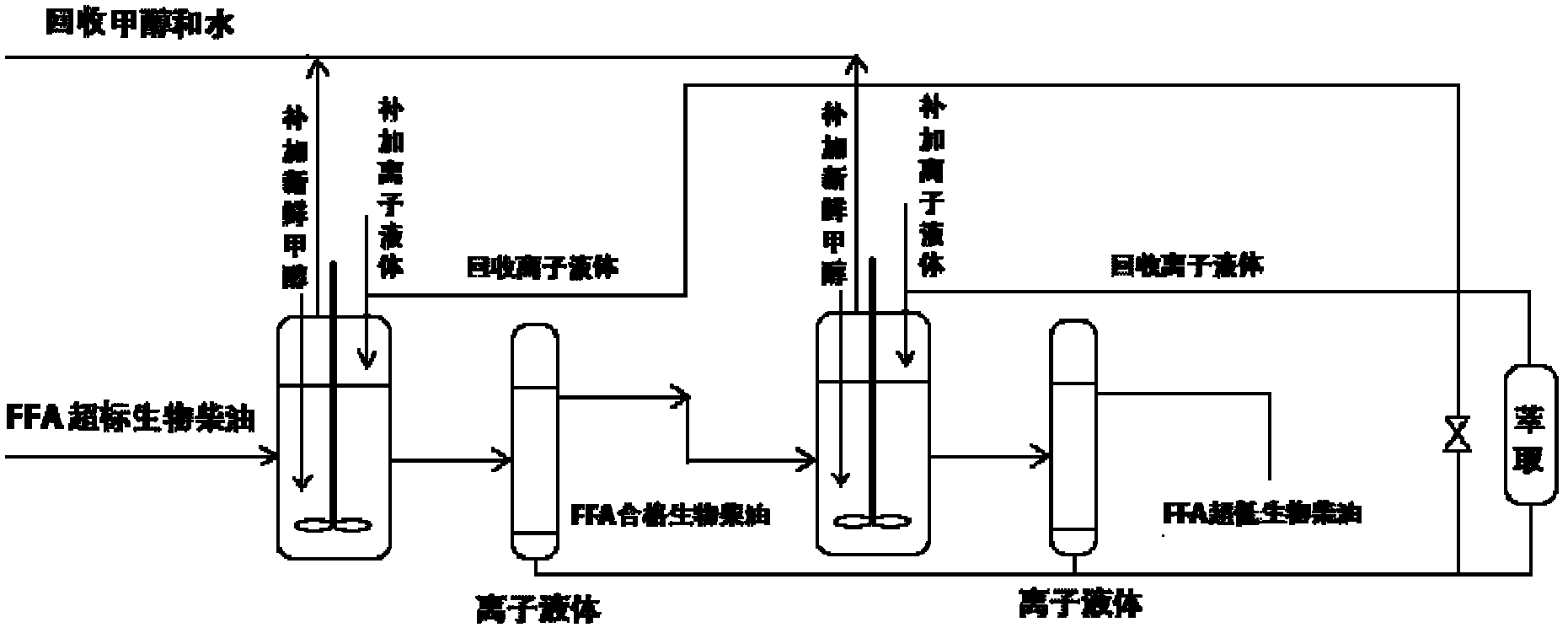

[0076] Biodiesel was prepared according to the method of Example 1, except that the method further included the following steps: 50 g of the upper oil phase prepared in Example 1 (about 5 g of free fatty acids), ionic liquid butyl methyl imidazole sulfonate B Acid ionic liquid (product grade AC 28, production plant: BASF, purity: > 94.5%) 0.4g, methanol 11g (about 14ml, the molar ratio of methanol to the upper oil phase is 2:1) was added with a stirrer, dropping funnel, distillation head and condensation In the reactor of the tube, the other end of the condenser tube is connected to a methanol collector. The reaction was carried out at 0.1MPa and 90°C. During the reaction, the unreacted methanol and the water generated by the reaction were distilled out of the reactor and collected in the methanol collection tank. At the same time, fresh methanol was slowly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com