Lithium ion capacitor and negative electrode plate thereof and manufacturing method of negative electrode plate

A negative pole piece and lithium ion technology, which is applied in the field of lithium ion capacitors and its negative pole piece and preparation, can solve problems such as difficult control, long pre-intercalation of lithium ions, uneven lithium intercalation, etc., and achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to the second aspect of the present invention, the preparation method of the lithium ion capacitor negative electrode sheet includes the steps of: coating the active material slurry on the current collector copper foil and drying and rolling, wherein the active material slurry contains embedded and / or The active material capable of extracting lithium ions; and spraying or sputtering the pre-lithiated slurry on the current collector copper foil after coating the active material slurry and drying, drying and rolling to obtain the negative electrode of the lithium ion capacitor piece.

[0033] In the preparation method of the lithium ion capacitor negative electrode sheet according to the second aspect of the present invention, preferably, the active material capable of inserting and / or extracting lithium ions is graphite, hard carbon, mesophase carbon microspheres, polycarbonate One or a mixture of acene and polyaniline.

[0034] In the preparation method of th...

Embodiment 1

[0047] Preparation of pre-lithiated slurry: LiF-coated passivated lithium powder, solvent tetrahydrofuran, and binder polyvinylidene fluoride were mixed and stirred at a mass ratio of 50:42:8 to prepare a uniformly dispersed lithiated slurry.

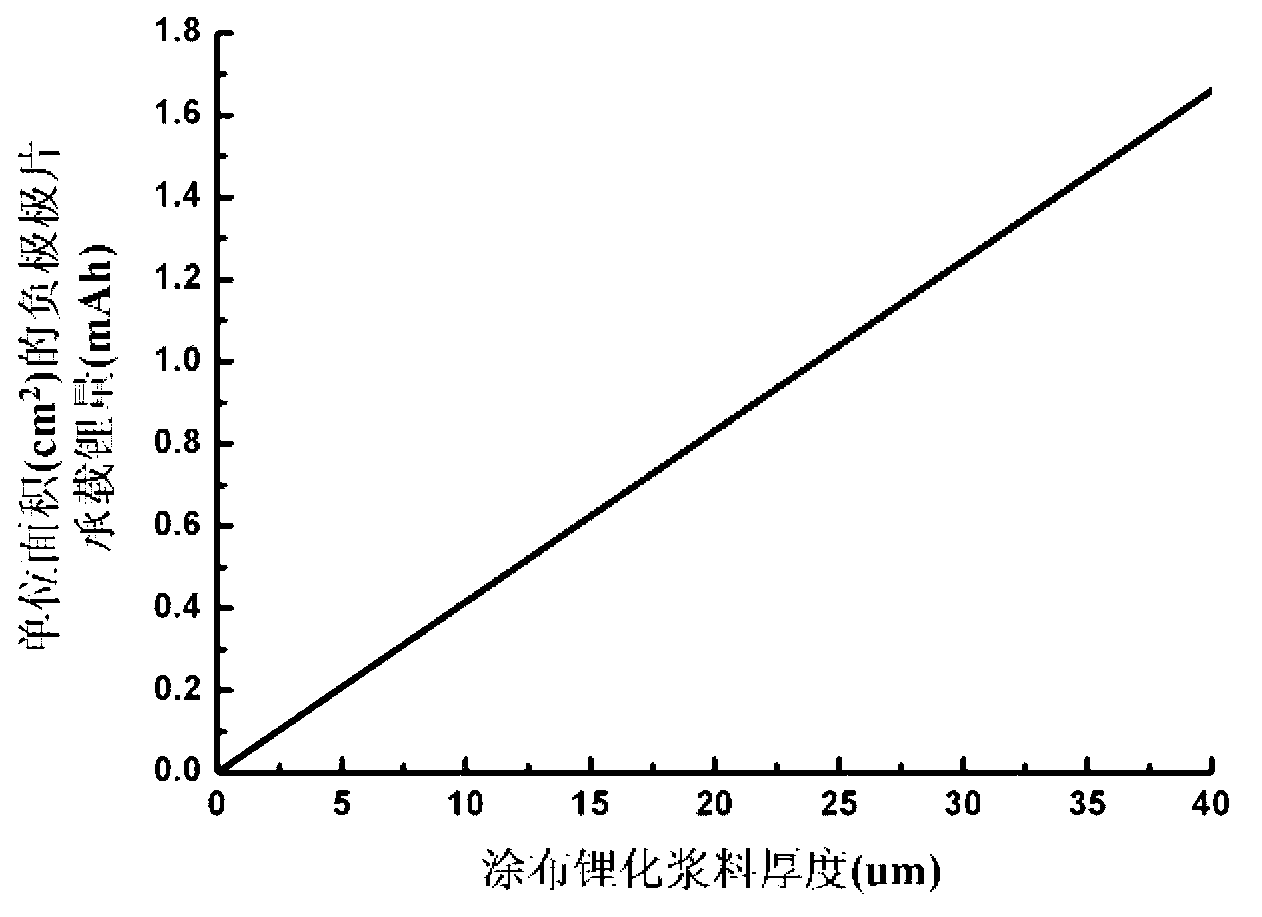

[0048] Preparation of lithium-ion capacitor negative pole piece: graphite (the graphite can be made of graphite for lithium-ion secondary battery negative material) and conductive agent (SuperP), binder polyvinylidene fluoride (PVDF) in a mass ratio of 90:3 : 7 make active material slurry, adopt coating machine to be coated on the current collector copper foil and dry at 120 ℃, coating thickness is 250 μ m, the thickness after drying and compacting is 50 μ m, after rolling again, The pre-lithiated slurry prepared above is coated with a coater; see figure 1 , the coating thickness of the pre-lithiated slurry in the present invention has a linear relationship with the amount of lithium carried by the negative electrode sheet. The coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compaction thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com