Method for preparing ethylene through ethanol dehydration

A technology for ethanol dehydration and ethylene, applied in chemical instruments and methods, catalyst activation/preparation, hydrocarbon production from oxygen-containing organic compounds, etc., can solve problems such as poor reaction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

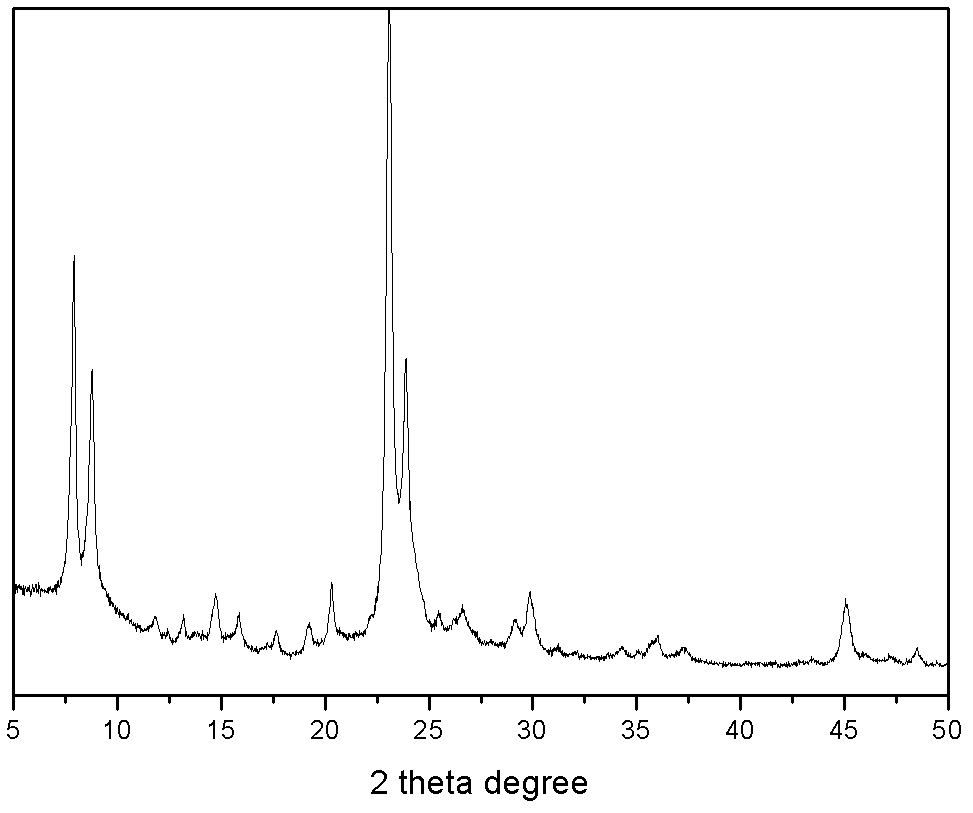

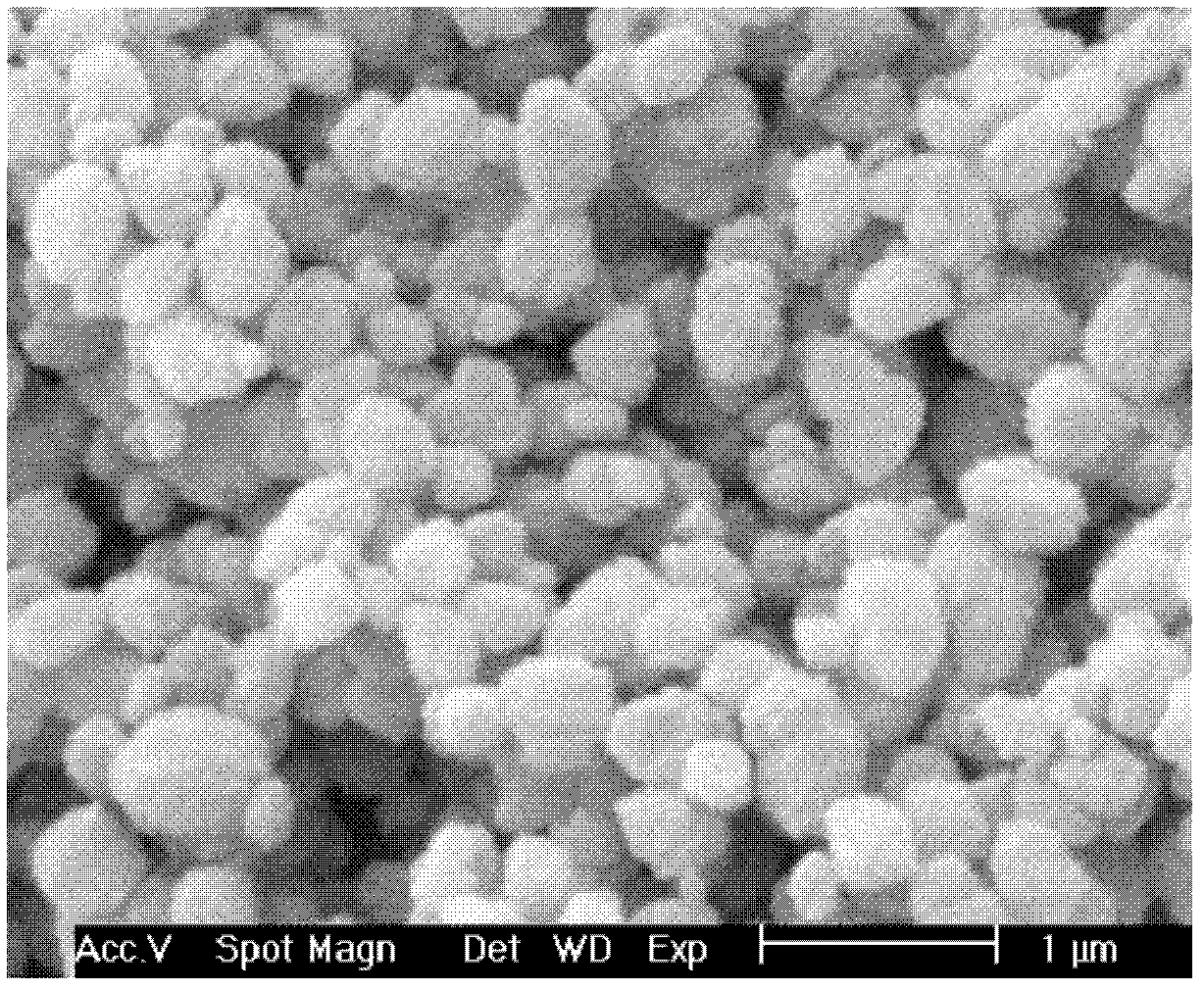

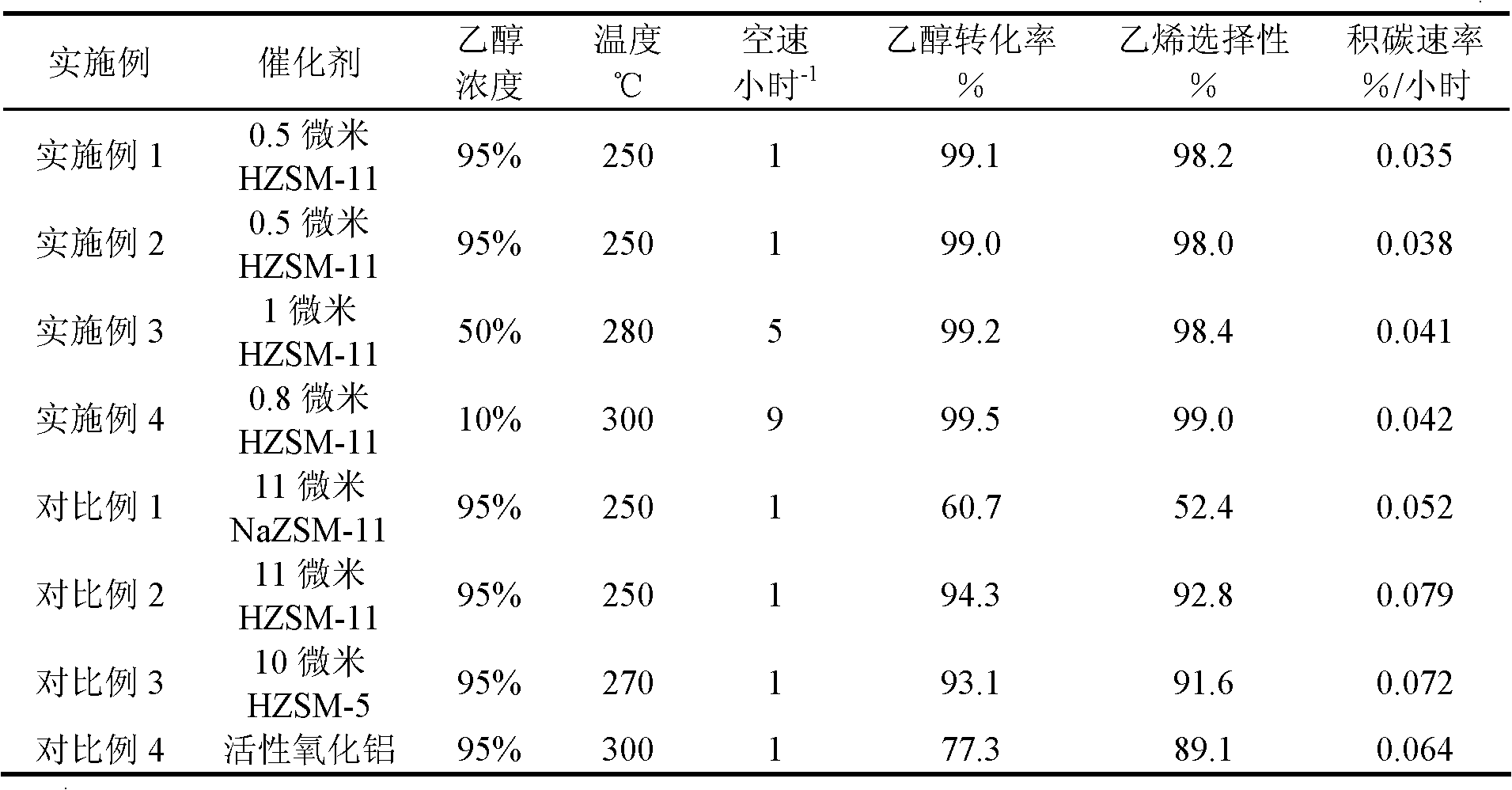

[0025] Mix 40% silica sol, sodium metaaluminate, tetrabutylammonium bromide, sodium chloride, sodium hydroxide and water, stir for 20 minutes, put into a reaction kettle, and crystallize at 170°C for 1 day. The crystallized product was quenched, filtered, and washed with water until the pH value was 8, and dried at 120°C for 12 hours to obtain the original powder of ZSM-11 molecular sieve. The XRD spectrum is shown in figure 1 , SEM photo see figure 2 , the grain diameter is 0.5 microns. The molar ratio of each raw material in the reaction mixture is: SiO 2 / Al 2 o 3 =149.3,H 2 O / SiO 2 =32.8, NaCl / SiO 2 =0.6, NaOH / SiO 2 = 0.08, TBABr / SiO 2 = 0.12.

[0026] The synthesized ZSM-11 molecular sieve raw powder was treated with 0.3 mol / L nitric acid at 80°C for 4 hours for 3 consecutive times to obtain HZSM-11.

[0027] Mix HZSM-11 with boehmite, Tianqing powder, and 0.3 mol / liter nitric acid, and the weight ratio of each raw material is ZSM-11 / Al 2 o 3 / Tian Qing powd...

Embodiment 2

[0030] Mix 40% silica sol, sodium metaaluminate, tetrabutylammonium bromide, sodium chloride, sodium hydroxide and water, stir for 20 minutes, put into a reaction kettle, and crystallize at 170°C for 1 day. The crystallized product was quenched, filtered, washed with water until the pH value was 8, and dried at 120°C for 12 hours to obtain ZSM-11 molecular sieve raw powder with a grain diameter of 0.5 microns. The molar ratio of each raw material in the reaction mixture is: SiO 2 / Al 2 o 3 =149.3,H 2 O / SiO 2 =32.8, NaCl / SiO 2 =0.6, NaOH / SiO 2 = 0.08, TBABr / SiO 2 = 0.12.

[0031] The synthesized ZSM-11 molecular sieve raw powder was treated with 0.3 mol / L hydrochloric acid at 80°C for 4 hours for 3 consecutive times to obtain HZSM-11.

[0032] Mix HZSM-11 with boehmite, Tianqing powder, and 0.3 mol / liter nitric acid, and the weight ratio of each raw material is HZSM-11 / Al 2 o 3 / Tian Qing powder = 1: 1: 0.1, extruded into strips, dried at 120°C for 12 hours, roasted ...

Embodiment 3

[0035] According to the steps and conditions of [Example 2], only SiO in the synthetic formula 2 / Al 2 o 3 =52, tetrabutylammonium hydroxide was used as template agent, crystallized at 120° C. for 8 days, and the crystal grain diameter of the synthesized ZSM-11 molecular sieve raw powder was 1 micron. Exchange with 1.0 mol / L citric acid at 80°C for 10 hours. A catalyst for ethanol dehydration to ethylene is obtained.

[0036] The performance of the catalyst was evaluated according to the steps of [Example 1]. The reaction conditions and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com