Neoprene adhesive and preparation method thereof

A neoprene and adhesive technology, applied in adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve problems such as poor storage stability, poor cold resistance, and poor heat resistance. Achieve the effect of low cost, good environmental protection and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

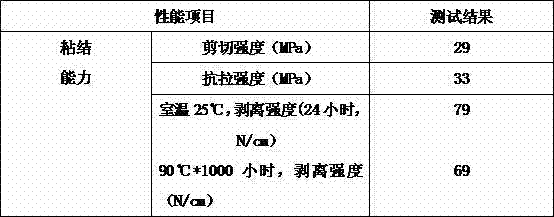

Examples

Embodiment

[0014] A neoprene adhesive, made of the following raw materials in parts by weight: 108 parts of chlorostyrene, 125 parts of ethyl acetate, 24 parts of neoprene CR121, 18 parts of xylene, 4,4'-diphenylmethane di 1.5 parts of isocyanate, 10 parts of polyisobutylene, 2 parts of 3-aminopropyltrimethoxysilane, 3 parts of polytetrahydrofuran ether glycol, 4 parts of SG-2 type PVC resin, 1.8 parts of ferrocene, 12 parts of chlorohydrin rubber H45 , 8 parts of polyvinyl alcohol, 5 parts of epoxidized soybean oil, 4 parts of n-butyl methacrylate, 1.5 parts of sodium bicarbonate, 0.8 parts of sulfur, 4 parts of magnesium oxide, 1 part of isooctyl tin dimethyl dimercaptoacetate , 12 parts of nano-bentonite, 10 parts of nano-bauxite, 15 parts of nano-silica, 1.6 parts of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate, 1.5 parts of antioxidant 1035, anti-aging agent NBC 1.2 parts, anti-aging agent 4010NA 1.8 parts, accelerator TMTD 1.5 parts, accelerator DM 1.5 parts, acceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com