Composite industrial fuel oil

A fuel oil and industrial technology, applied in the field of renewable energy fuels, to achieve the effects of reducing use costs, reducing pollutant emissions, and saving oil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

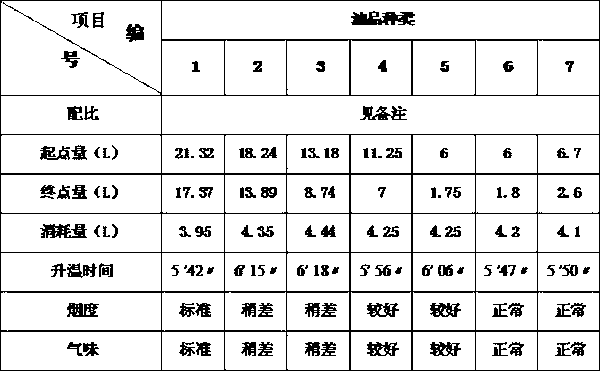

Examples

preparation example Construction

[0034] The preparation process of the composite industrial fuel of the present invention is as follows.

[0035] First put the composite additive and combustion improver into the modified coal tar to dissolve in proportion, then put the biodiesel into the modified coal tar according to the above proportion and mix evenly, and it can be stabilized for 5-8 hours.

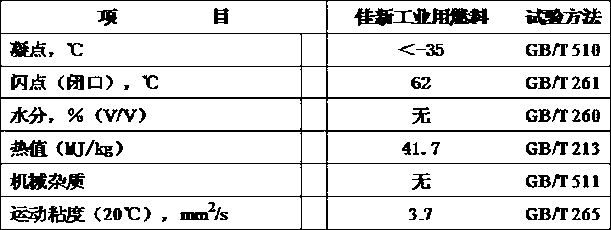

[0036] Compared with the prior art, the present invention is composed of modified coal tar, biodiesel and various additives. After the optimization of each component, it can significantly improve the fuel economy and environmental protection, and has the advantages of energy saving, economical , convenience and other features, as follows:

[0037] 1. Excellent performance: the fuel effect is better than that of diesel, heavy oil, residual oil and other fuel oils, with complete combustion, high thermal efficiency, good atomization, and strong firepower.

[0038] 2. Safety and environmental protection: On the premise o...

Embodiment 1

[0044] Example 1: (1 liter per serving)

[0045]A kind of compound industrial fuel oil, this fuel oil is made up of the raw material of following volume number: 50 parts of modified coal tars, 29 parts of biodiesel, 0.2 parts of composite additives, 0.6 parts of combustion aids, among the above-mentioned raw materials, described modified The density of coal tar at 20°C is 1.035-1.06g / ml, the distillation range is 230-300°C, the phenol content is less than 0.5%, the naphthalene content is less than 0.5%, and the viscosity E50 is greater than 1.5%; the composite additive is diethanolamine or triethanolamine or 2,6-di-tert-butyl-p-cresol; the combustion enhancer is non-aromatic hydrocarbon, aromatic hydrocarbon C8 or aromatic hydrocarbon C9. During preparation, the composite additives and combustion accelerants are put into the modified coal tar in proportion to be dissolved, and then the biodiesel is put into the modified coal tar in the above proportion and mixed evenly, and it...

Embodiment 2

[0046] Example 2: Each serving is 10 liters

[0047] A kind of compound industrial fuel oil, this fuel oil is made up of the raw material of following volume: 70 parts of modified coal tar, 49 parts of biodiesel, 0.4 part of composite additive, 0.8 part of combustion aid, among the above raw materials, described modified The density of coal tar at 20°C is 1.035-1.06g / ml, the distillation range is 230-300°C, the phenol content is less than 0.5%, the naphthalene content is less than 0.5%, and the viscosity E50 is greater than 1.5%; the composite additive is diethanolamine It is mixed with triethanolamine in any proportion; the combustion accelerant is calcium naphthenate, magnesium naphthenate or iron naphthenate. During preparation, the composite additives and combustion accelerants are put into the modified coal tar in proportion to be dissolved, and then the biodiesel is put into the modified coal tar in the above proportion and mixed evenly, and it is ready after being stabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com