Desulphurization phosphomolybdic acid catalyst and its preparation method

A desulfurization catalyst, phosphomolybdic acid technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of polluted environment, complicated post-processing, corroded equipment, etc., to achieve high sulfur recovery rate, desulfurization The effect of strong removal of organic sulfur and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

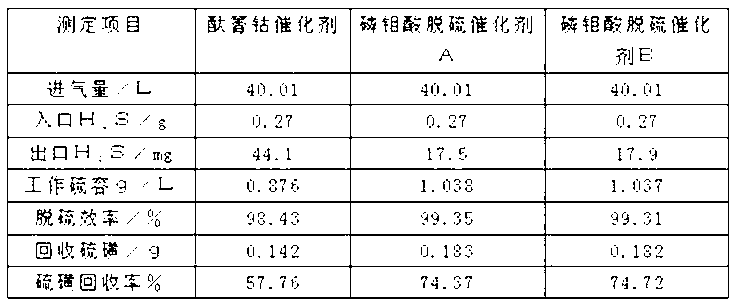

Embodiment 1

[0022] Take 800g of phosphomolybdic acid (phosphomolybdenum heteropoly acid), add 600g of phthalic anhydride and 200g of urea, put it into a reaction kettle with a stirring device and stir evenly, slowly add 300g of ammonia water and heat evenly to 150-160°C, stop Heating, keep heating for 2-3 hours, start heating to 200°C, keep at 200°C for 6-8 hours, then carry out sampling inspection, if it can be dissolved in water immediately, the heating is over, cool down to 50°C and discharge, Filter the viscous material, put the filtered intermediate product I into another reaction kettle with a stirring device, add 180g of cobalt chloride and stir evenly to obtain the intermediate product II, then take out the intermediate product II and put it in an electric heating box for further Heating, slowly raising the temperature to 200°C for uniform heating and mass transfer. When the temperature is further raised to 260°C, keep the synthesis for 3 hours to form a light yellow solid, take it...

Embodiment 2

[0024] Take 1000g of phosphomolybdic acid (phosphomolybdenum heteropoly acid), add 800g of phthalic anhydride and 200g of urea, put it into a reaction kettle with a stirring device and stir evenly, slowly add 400g of ammonia water and heat evenly to 160-180°C, stop Heating, keep the reaction for 3 hours, then start heating to 240°C, keep heating for 4-5 hours, then take a sample test, if it can be dissolved in water immediately, the heating is over, cool down to 50°C and discharge, the viscous The material is filtered, and the filtered intermediate product I is put into another reaction kettle with a stirring device, and then 140 g of cobalt chloride is added and stirred evenly to obtain the intermediate product II, and then the intermediate product II is taken out and put into an electric heating box for heating. Slowly raise the temperature to 200°C in order to achieve uniform heating and mass transfer. When the temperature is further raised to 260°C, keep the synthesis for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com