Compound microorganism bacterium agent of biological coalbed methane prepared by coal bed organic impurities and application thereof

A compound microbial agent and bio-coal bed gas technology, applied in the direction of micro-organisms, micro-organism-based methods, biochemical equipment and methods, etc., can solve the problem of unknown ratio and synergy between strains, operation intervention of coal-bed methane production process, and lack of stability Sexuality and other problems, to achieve the effect of shortening the anaerobic digestion time, good effect and long action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] Example 2 Utilizing a composite microbial bacterial agent to treat coalbed methane produced by anaerobic fermentation of coal in Inner Mongolia

[0035] 1, four kinds of microbial fermented liquids prepared in embodiment 1 are mixed uniformly by following weight parts and become compound microbial inoculum: 8 weight parts of Phanerochaete chrysosporium fermented liquids, 5 weight parts of Penicillium chrysogenum fermented liquids, Pseudomonas cepacia 10 parts by weight of bacteria fermentation liquid, 7 parts by weight of Clostridium acetobutylicum fermentation liquid;

[0036] 2. Select 50kg of coal from a coal mine in Inner Mongolia (sealed quickly after on-site sampling), divide it into 5 parts on average, and add them to 5 15L anaerobic reaction tanks respectively;

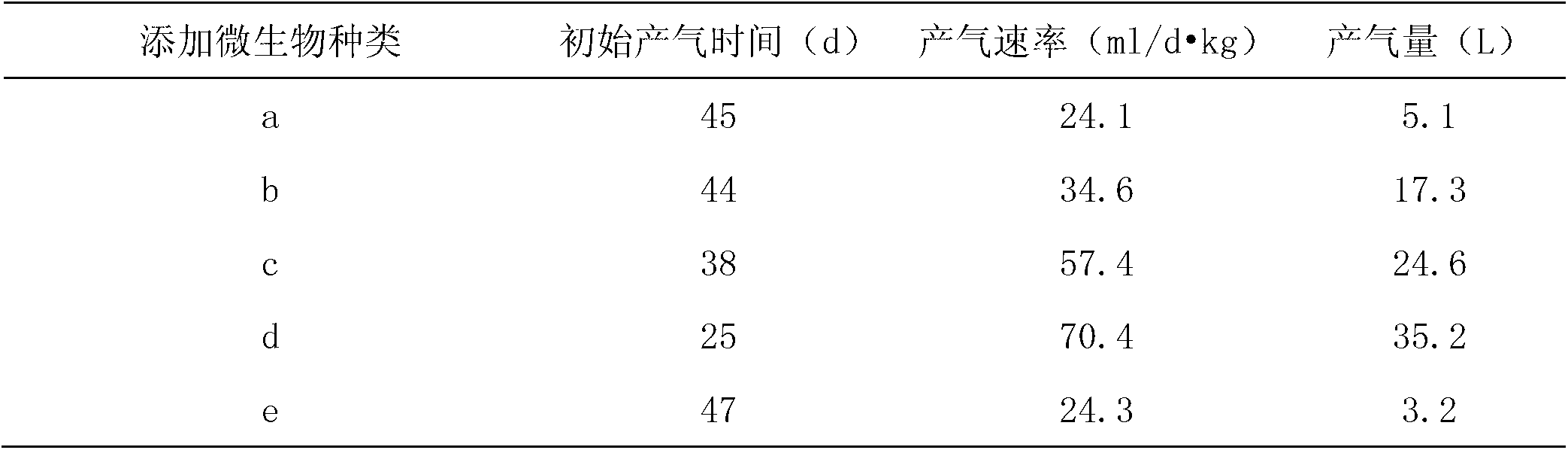

[0037] 3. Add 80ml of the following microbial fermentation liquid or microbial fermentation liquid mixture to the four anaerobic reaction tanks respectively: a: Phanerochaete chrysosporium fermentation ...

Embodiment 3

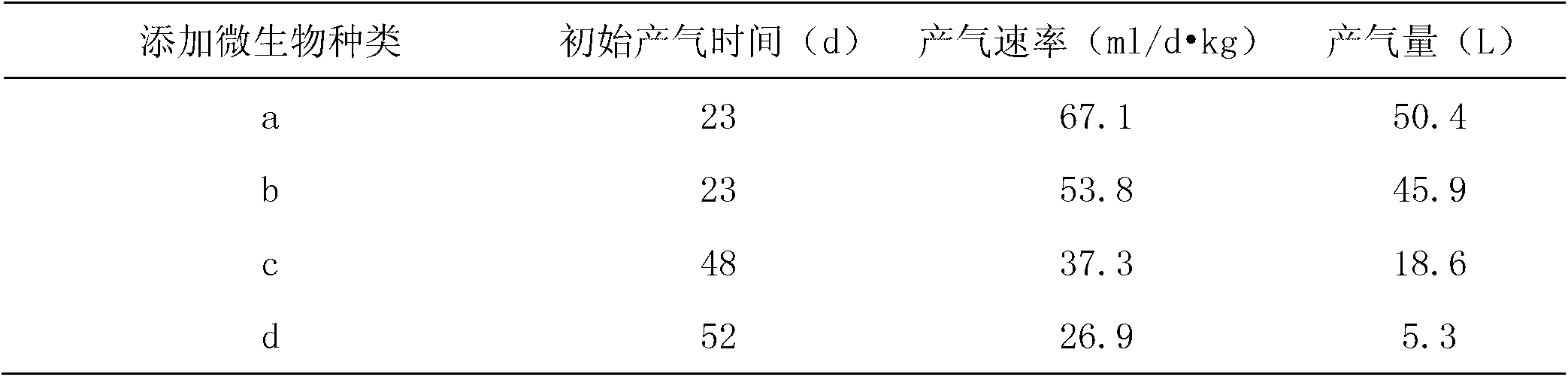

[0042] Example 3 Utilizing composite microbial bacterial agent to process coal bed methane produced by anaerobic fermentation of coal in Gansu

[0043] 1. Replace the 4 microorganisms in Example 1 with the following sources: Phanerochaete chrysosporium (CICC40719), Penicillium chrysogenum (ACCC32009), Pseudomonas cepacia (CICC20699), Clostridium acetobutylicum (CGMCC1.135); Prepare four kinds of microbial fermented liquids according to the method of Example 1, and mix uniformly by the following parts by weight to become composite microbial inoculum I: 11 parts by weight of Phanerochaete chrysosporium fermented liquid, Penicillium chrysogenum fermented liquid 6 parts by weight, 8 parts by weight of Pseudomonas cepacia fermentation broth, 14 parts by weight of Clostridium acetobutylicum fermentation broth; mix uniformly according to the following parts by weight to become composite microbial bacterial agent II: Phanerochaete chrysosporium fermentation broth 26 The parts by weigh...

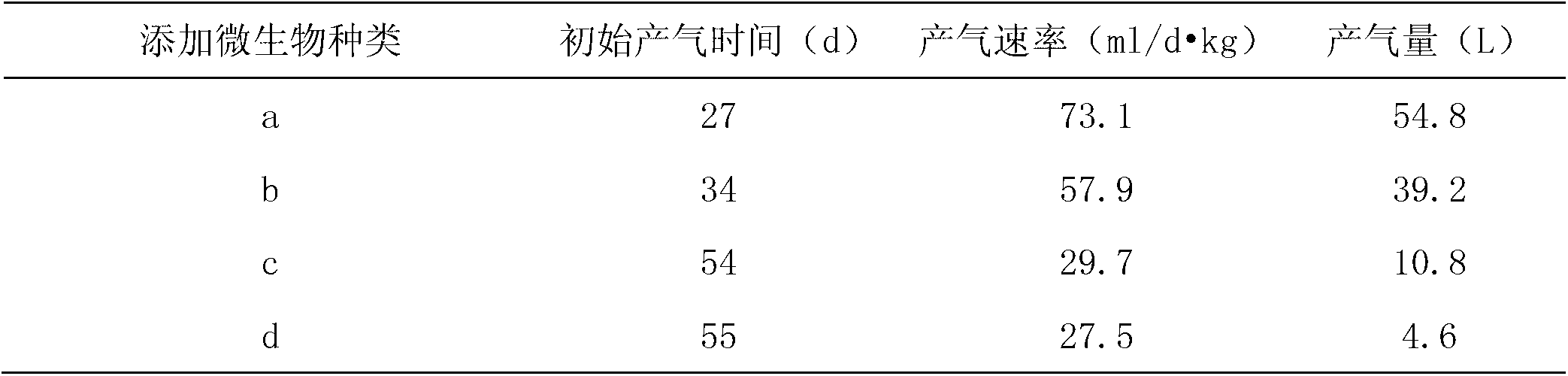

Embodiment 4

[0051] 1. Replace Phanerochaete chrysosporium (ATCC20696) in Example 1 with Phanerochaete chrysosporium (CICC40719), Clostridium acetobutylicum (ATCC824) with Clostridium acetobutylicum (CGMCC1 .135), prepare four kinds of microbial fermented liquids according to the method of Example 1, and mix uniformly according to the following proportions to become composite microbial inoculum I: 6 parts by weight of Phanerochaete chrysosporium fermented liquid, 4 parts by weight of Penicillium chrysogenum fermented liquid , 12 parts by weight of Pseudomonas cepacia fermented liquid, 12 parts by weight of Clostridium acetobutylicum fermented liquid; mix uniformly by the following parts by weight to become composite microbial bacterial agent II: 7 parts by weight of Phanerochaete chrysosporium fermented liquid, 6 parts by weight of Penicillium chrysogenum fermentation liquid, 2 parts by weight of Pseudomonas cepacia fermentation liquid, and 23 parts by weight of Clostridium acetobutylicum f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com