Preparation method of core-shell structured micro-nanosphere comprising magnetic core and magnesium silicate nano-sheet shell

A technology of micro-nanosphere and core-shell structure, which is applied in the direction of microsphere preparation, nanotechnology, microcapsule preparation, etc., can solve the problems of difficult separation, easy agglomeration, small adsorption capacity, etc., and achieve large morphology and good removal effect , The effect of the novel preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

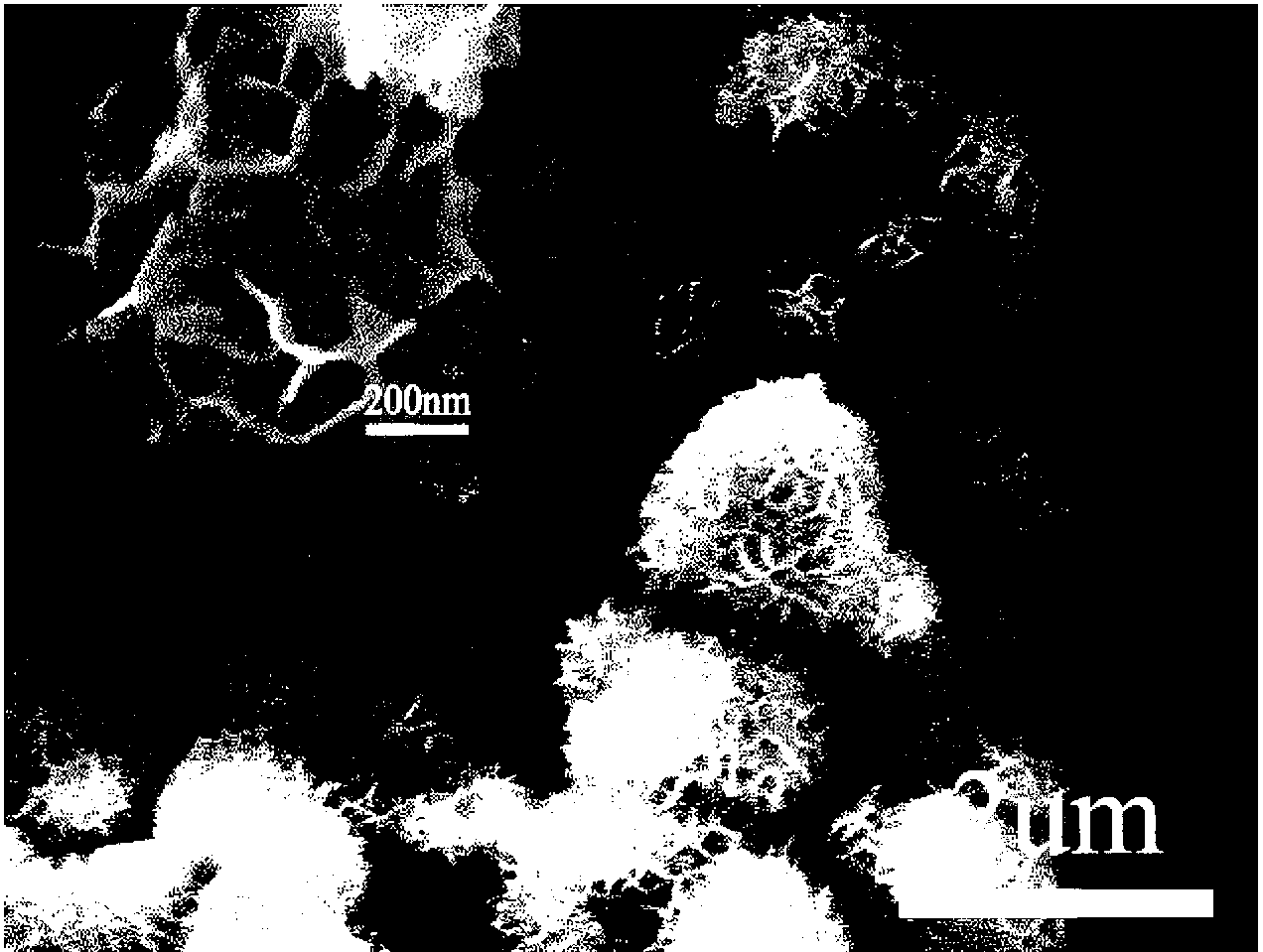

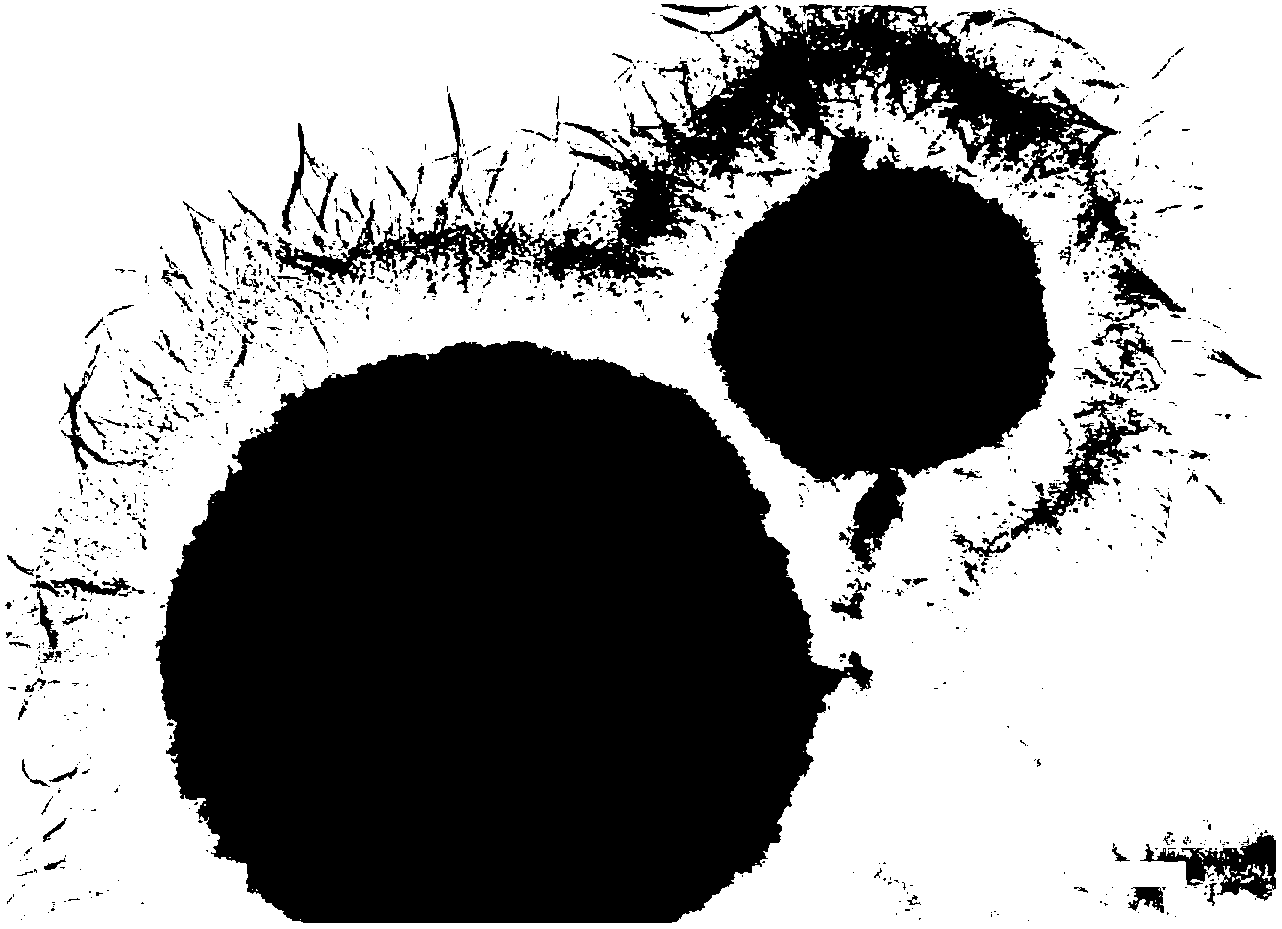

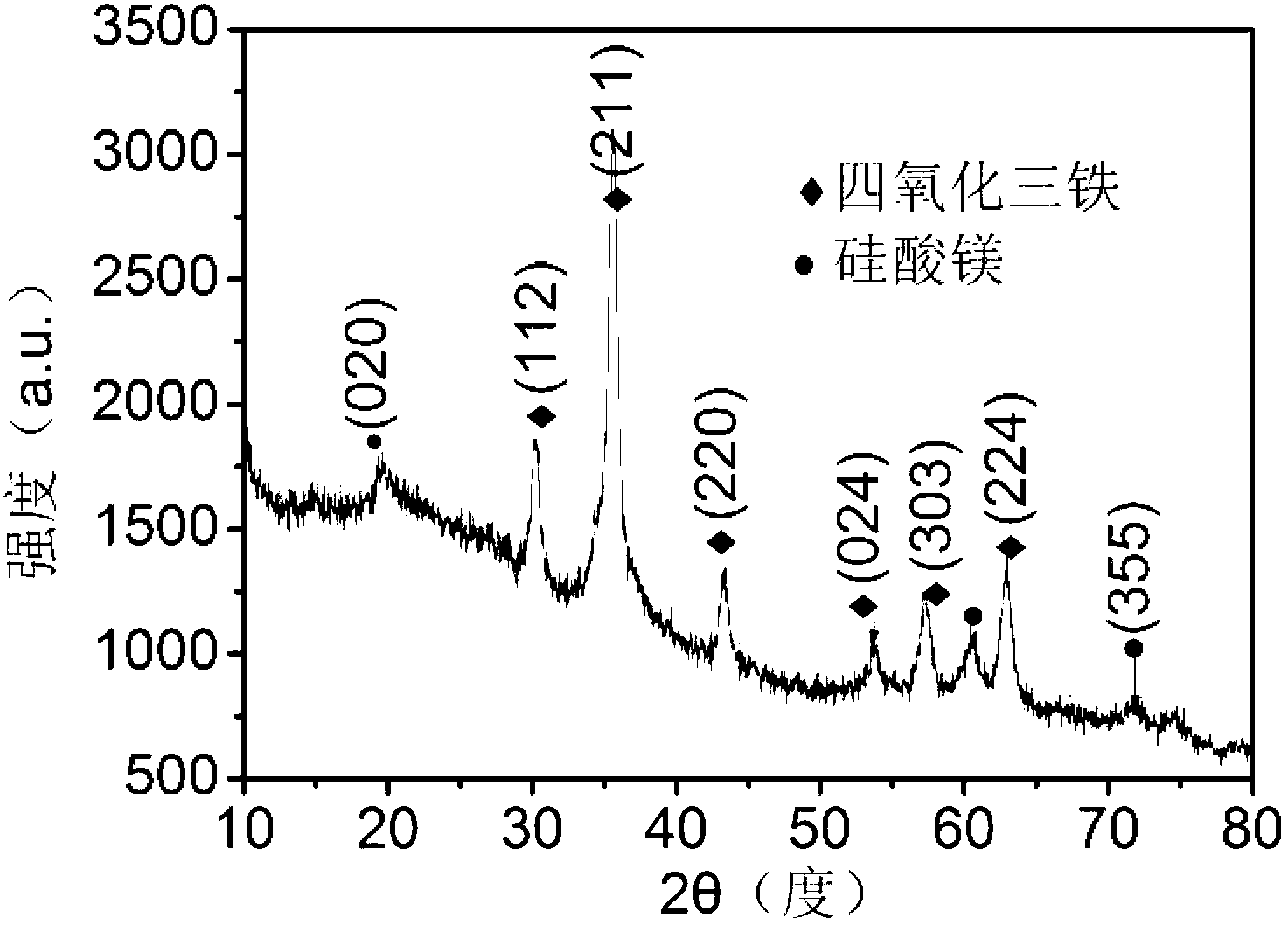

[0014] Preparation of a core-shell micro-nanosphere composed of a magnetic core and a magnesium silicate nanosheet shell:

[0015] (1) Preparation of monodisperse iron ferric oxide nanospheres: 5 mmol of ferric chloride hexahydrate and 3.6 g of sodium acetate were added to 40 ml of ethylene glycol solution, magnetically stirred for 2 hours to form a uniformly mixed solution, and then 1.0 g of poly Ethylene, magnetically stirred for 30min, then put the above mixed solution into a polyvinyl fluoride autoclave with a volume of 70ml; put the polyvinyl fluoride autoclave into a blast drying oven and heat it to 200°C and keep it warm for 8h; After the tetrafluoroethylene autoclave is naturally cooled, take out the reaction product, wash it repeatedly with deionized water and absolute ethanol, and finally put the product in a vacuum drying oven at 65-75 ° C for 5-8 hours to obtain the final product which is very dispersible Good ferroferric oxide nanospheres.

[0016] (2) Core-sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com