Method for synthesizing monascus yellow pigment through direct electroreduction of monascus red pigment

A technology of monascus red pigment and monascus yellow pigment, applied in the field of direct electroreduction of monascus red pigment to synthesize monascus yellow pigment, achieving obvious economic benefits and application prospects, low production cost and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

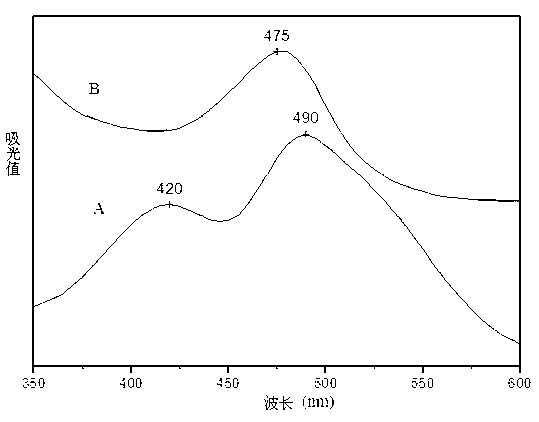

Image

Examples

Embodiment 1

[0020] (1) Preparation of red pigment solution: Dissolve Monascus red pigment with a small amount of ethanol, add distilled water to make 10% red pigment solution 10L, add a certain amount of NaCl to make the NaCl concentration 0.1mol / L.

[0021] (2) Assembly of the electrolytic cell: the electrolytic cell adopts a diaphragm electrolytic cell, and the anode and cathode chambers are separated by Nafion117 cationic membrane (DuPont, USA) in the middle, and the solution in the anode chamber is 1mol / L Na 2 SO 4 , the cathode chamber is the above-mentioned monascus pigment solution, the cathode chamber is equipped with a stirrer, the stirring speed is 1000r / min, graphite electrodes are used for the cathode and anode, and a DC power supply is used.

[0022] (3) Electrocatalytic reduction process: use constant current method for electrolysis, the current is 10-50mA, pay attention to control the current during the reduction process to prevent the generation of hydrogen, and react unti...

Embodiment 2

[0026] (1) Preparation of red pigment solution: Dissolve Monascus red pigment with a small amount of ethanol, add distilled water to prepare 10L of 30% red pigment solution, add a certain amount of NaCl to make the NaCl concentration 1mol / L.

[0027] (2) Assembly of the electrolytic cell: the electrolytic cell adopts a diaphragm electrolytic cell, and the cathode and anode chambers are separated by a bipolar membrane in the middle. The solution of the anode chamber is 1mol / L NaCl, the cathode chamber is the above-mentioned monascus pigment solution, and the cathode chamber is equipped with stirring The stirring speed is 1000r / min, the cathode adopts copper electrode, the anode adopts stainless steel electrode, DC power supply.

[0028] (3) Electrocatalytic reduction process: Electrolysis is carried out in a constant current mode with a current of 10-50mA. During the reduction process, attention should be paid to controlling the current to prevent the generation of hydrogen, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com