Method for preparing ionic imprinting microsphere by taking crown ether as functional monomer in inverse emulsion method

A functional monomer, inverse emulsion technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effects of large adsorption capacity, simple operation and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

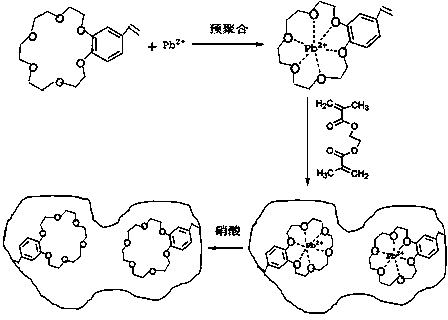

[0033] Applying the contents of the present invention, lead ions are used as template ions to prepare crown ether ion-imprinted polymers.

[0034] The preparation of the crown ether ion-imprinted polymer using lead ions as a template comprises the following steps:

[0035] a. Dissolve 0.5 ml Siben-80 and 5 ml EGDMA in 10 ml toluene and N,N-dimethylformamide, then add 350 mg functional monomer 4-vinylphenylpropane-18-crown-6, An oil phase is formed; 331.21 mg of lead nitrate is dissolved in water and fully dissolved to form an inner water phase;

[0036] b. Slowly add the water phase to the oil phase, and ultrasonicate for 5 minutes to form a uniform milky white W / O phase;

[0037] c. The external water phase is 150 ml of 0.2 mol / L SDBS aqueous solution, blow nitrogen gas for 5 minutes to remove oxygen, slowly add the W / O phase into the external water phase, and after the W / O / W inverse emulsion is formed, add 5 g of initiator ammonium persulfate, connected to the condenser, s...

Embodiment 2

[0042] Applying the contents of the present invention, lead ions are used as template ions, and 4-vinylphenylpropane-15-crown-5 is used as functional monomer to prepare ion-imprinted polymers.

[0043] The preparation of the crown ether ion-imprinted polymer using lead ions as a template comprises the following steps:

[0044] a. Dissolve 0.5 ml Siben-80 and 5 ml EGDMA in 10 ml toluene and N,N-dimethylformamide, then add 350 mg functional monomer 4-vinylphenylpropane-18-crown-5, An oil phase is formed; 331.21 mg of lead nitrate is dissolved in water and fully dissolved to form an inner water phase;

[0045] b. Slowly add the water phase to the oil phase, and ultrasonicate for 5 minutes to form a uniform milky white W / O phase;

[0046] c. The external water phase is 150 ml of 0.2 mol / L SDBS aqueous solution, blow nitrogen gas for 5 minutes to remove oxygen, slowly add the W / O phase into the external water phase, and after the W / O / W inverse emulsion is formed, add 5 g of initi...

Embodiment 3

[0051] Applying the contents of the present invention, cadmium ions are used as template ions and 4-vinylphenylpropane-18-crown-6 is used as functional monomer to prepare ion imprinted polymers.

[0052] The preparation of the crown ether ion imprinted polymer using cadmium ion as a template comprises the following steps:

[0053] a. Dissolve 0.5 ml Siben-80 and 5 ml EGDMA in 10 ml toluene and N,N-dimethylformamide, then add 350 mg functional monomer 4-vinylphenylpropane-18-crown-6, An oil phase is formed; 183.4 mg of cadmium chloride is dissolved in water and fully dissolved to form an inner water phase;

[0054] b. Slowly add the water phase to the oil phase, and ultrasonicate for 5 minutes to form a uniform milky white W / O phase;

[0055] c. The external water phase is 150 ml of 0.2 mol / L SDBS aqueous solution, blow nitrogen gas for 5 minutes to remove oxygen, slowly add the W / O phase into the external water phase, and after the W / O / W inverse emulsion is formed, add 5 g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com