Preparation method of graphene/TiO2 flower-like nano-clusters

A technology of graphene and nanoclusters, applied in nanotechnology, coatings, surface reaction electrolytic coatings, etc., can solve the problems of ineffective transfer of carriers, low utilization of sunlight, and low conductivity, and achieve increased The effect of photocatalytic efficiency, simple and safe preparation process, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Graphene / TiO 2 Preparation of flower-like nanoclusters

[0022] ① Use 320#, 600#, 800#, 1200#, 2000# sandpaper to polish the titanium sheet (a titanium foil with a thickness of 0.3mm, a size of 30mm×40mm, and a purity of 99.99%). Ultrasound in absolute ethanol and high-purity water for 15 minutes, then repeatedly rinse with high-purity water, dry at 55°C, and set aside.

[0023] ② Configure electrolyte: add 5mg graphene to 50ml of 0.1mg / ml magnesium nitrate solution, the mass ratio of graphene to magnesium nitrate is 1:1, ultrasonic for 30min and mix well.

[0024] ③Under the condition of 60V DC voltage, the treated titanium sheet is used as the anode and the platinum wire is used as the cathode. In the above electrolyte, anodize for 2 minutes.

[0025] ④ After the reaction, the titanium flakes are washed repeatedly with deionized water, and then calcined in a muffle furnace at 500°C for 2 hours after drying.

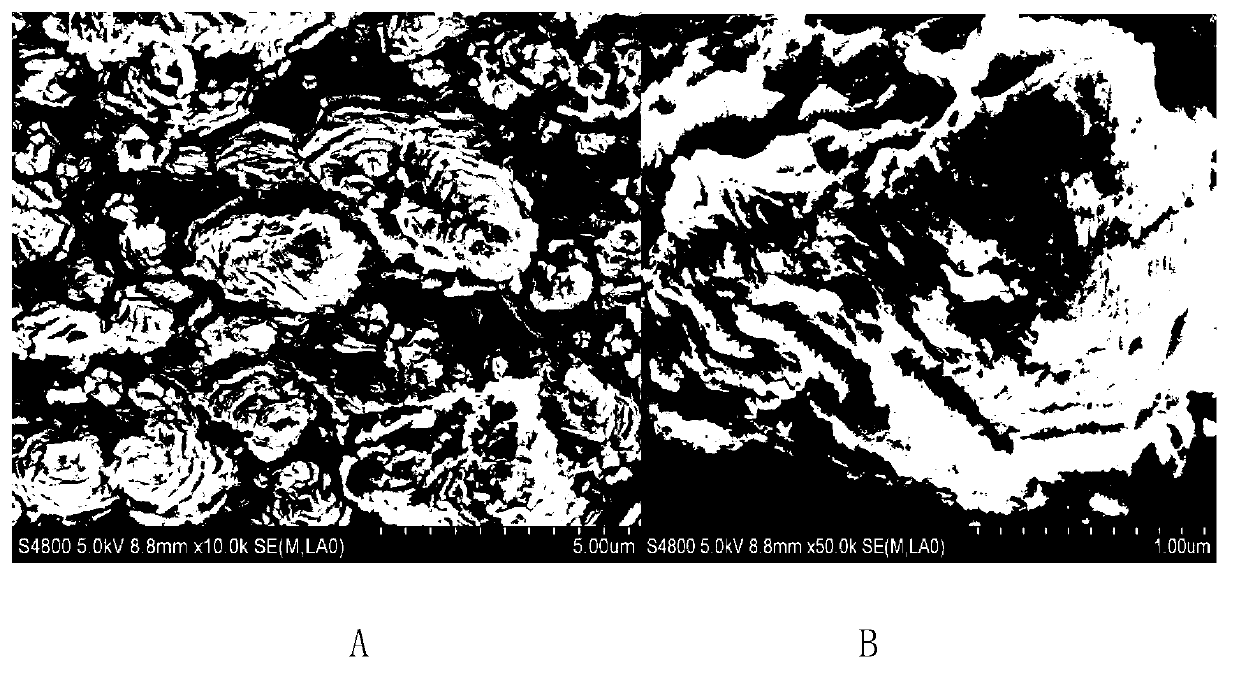

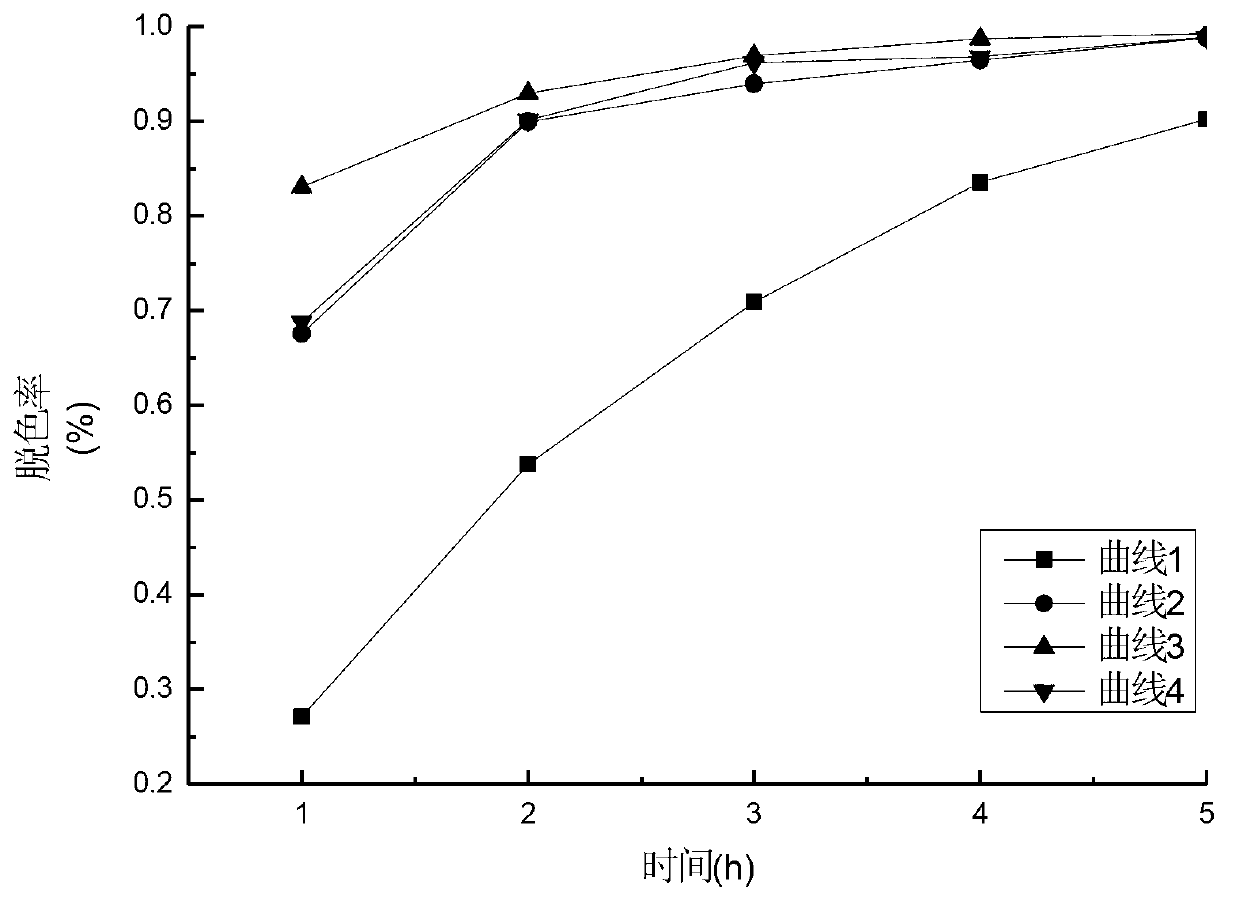

[0026] Graphene / TiO grown on the surface of titanium sheet 2 Flo...

Embodiment 2

[0033] (1) Graphene / TiO 2 Preparation of flower-like nanoclusters

[0034] ①After polishing the titanium sheet with 320#, 600#, 800#, 1200#, 2000# sandpaper in turn, it is sonicated in acetone, absolute ethanol, and high-purity water for 15 minutes, then rinsed repeatedly with high-purity water, and dried at 55°C. ,spare.

[0035] ② Configure the electrolyte: add 2.5 mg of graphene to 50 ml of 0.1 mg / ml magnesium nitrate solution, the mass ratio of graphene to magnesium nitrate is 1:2, and ultrasonic for 30 minutes to mix well.

[0036] ③Under the condition of 70V DC voltage, the treated titanium sheet is used as the anode and the platinum wire is used as the cathode. In the above electrolyte, anodize for 2 minutes.

[0037] ④ After the reaction, the titanium flakes are washed repeatedly with deionized water, and then calcined in a muffle furnace at 500°C for 2 hours after drying.

[0038] Graphene / TiO grown on the surface of titanium sheet 2 Flower-like nano clusters.

[0039] (2) Grap...

Embodiment 3

[0043] (1) Graphene / TiO 2 Preparation of flower-like nanoclusters

[0044] ①After polishing the titanium sheet with 320#, 600#, 800#, 1200#, 2000# sandpaper in turn, it is sonicated in acetone, absolute ethanol, and high-purity water for 15 minutes, then rinsed repeatedly with high-purity water, and dried at 55°C. ,spare.

[0045] ② Configure the electrolyte: add 0.5 mg of graphene to 50 ml of 0.1 mg / ml magnesium nitrate solution, the mass ratio of graphene to magnesium nitrate is 1:10, and ultrasonic for 30 minutes to mix well.

[0046] ③Under the condition of 80V DC voltage, the treated titanium sheet is used as the anode and the platinum wire is used as the cathode. In the above electrolyte, anodize for 2 minutes.

[0047] ④ After the reaction, the titanium flakes are washed repeatedly with deionized water, and then calcined in a muffle furnace at 500°C for 2 hours.

[0048] Graphene / TiO grown on the surface of titanium sheet 2 Flower-like nano clusters.

[0049] (2) Graphene / TiO 2 F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com