Ultrafiltration membrane with hydrophilism and antibacterial property and preparation method thereof

An ultrafiltration membrane and antibacterial technology, applied in the field of ultrafiltration membrane and its preparation, can solve the problems of reduced anti-fouling performance of membrane, poor dispersion of nano-silver, loss of silver particles, etc., and achieve excellent anti-protein adsorption and antibacterial ability, dispersion Good performance and loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

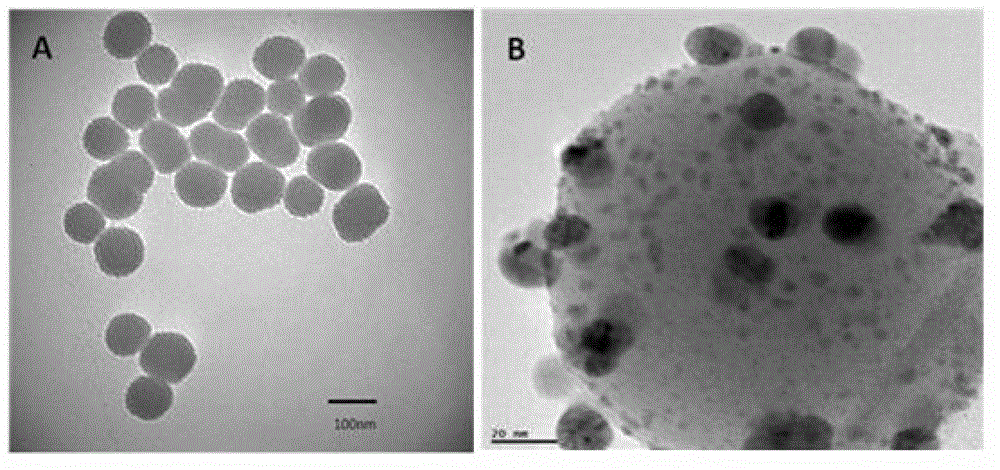

[0037] 104.2 g of tetraethyl orthosilicate was added to a solution consisting of 18 g of pure water and 1000 mL of absolute ethanol, stirred evenly, and then 98 g of ammonia water was added as a catalyst, and the whole reaction was carried out under stirring for 12 hours. After the reaction, the resulting solution was dried at about 80 °C, ground and sieved to obtain silica powder. Take 3 grams of silica powder and disperse it in 500 mL of pure water, add 1.5 grams of AgNO 3 and 7.2 grams of ammonia water, reacted for 12 h under stirring, centrifuged, washed several times with absolute ethanol, centrifuged, and dried at room temperature to obtain Ag-SiO 2 Antibacterial agents.

Embodiment 2

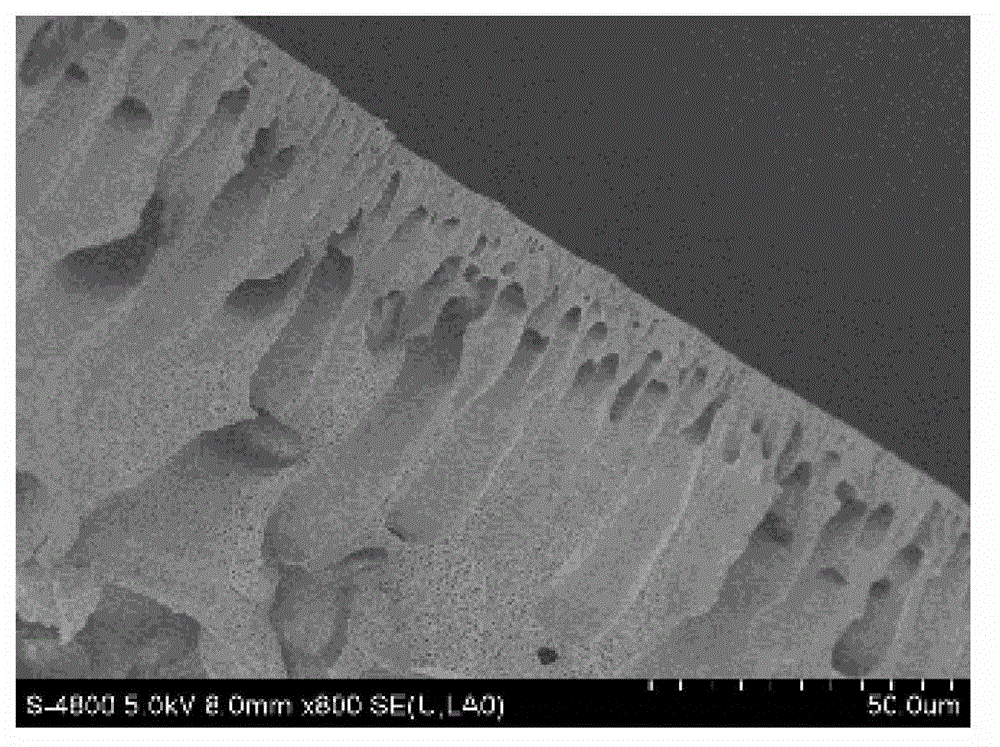

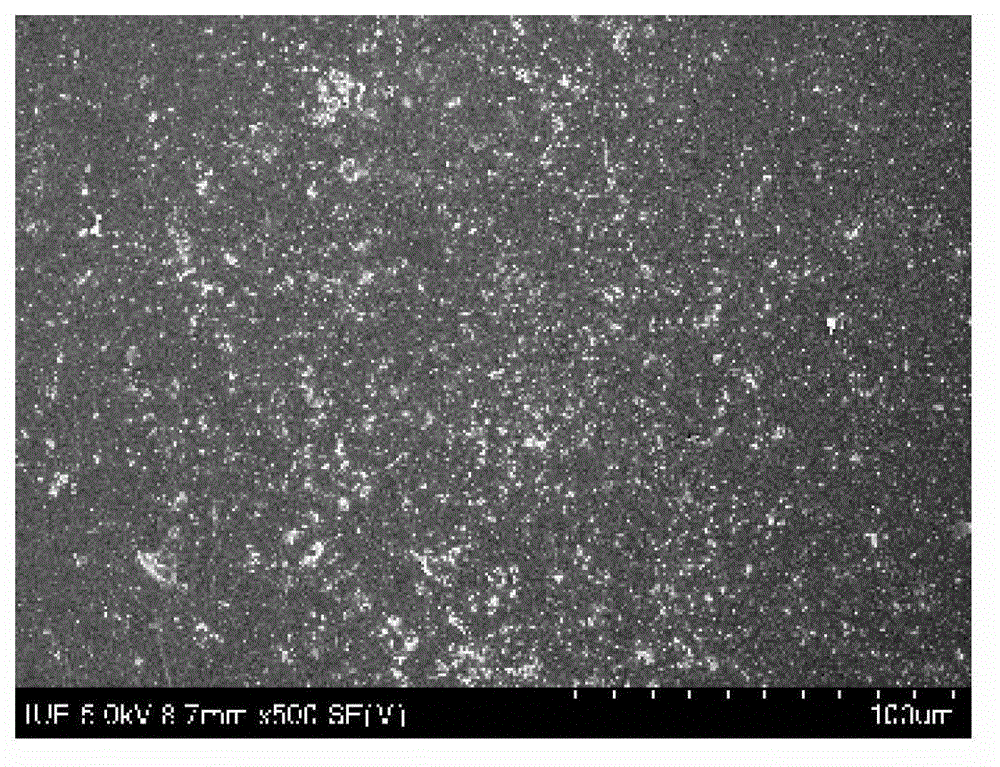

[0039] 0.5 g of Ag-SiO prepared according to Example 1 2Add 4 g polyethylene glycol-400 to 77.5 g N,N-dimethylacetamide, stir well, then add 18 g polyethersulfone, dissolve the mixture at 60 °C, and heat at 70 °C Degassing to obtain casting solution. A certain amount of casting liquid was scraped onto the non-woven fabric with a scraper, and the thickness of the film was controlled to 0.25 mm by a feeler gauge, and then entered into a coagulation bath to solidify to form a film. The prepared membrane was placed in pure water for more than 24 h to completely remove excess organic solvent. At a pressure of 0.1 MPa, the membrane has a pure water flux of 221 L / m 2 h, the rejection rate to 1g / L BSA is 98%. The surface contact angle of the composite membrane measured by a contact angle measuring instrument is 52.6°, indicating that it has good hydrophilicity, and the 24-hour protein adsorption amount on the membrane surface is only 41.2ug / m3 measured with 1g / L BSA solution 2 . ...

Embodiment 3

[0041] Polyvinylidene fluoride (PVDF) was used as the membrane material, N,N-dimethylformamide (DMF) was used as the organic solvent, and polyvinylpyrrolidone (PVP) was used as the porogen to prepare the antibacterial membrane. Concrete steps are as follows, the Ag-SiO that 1g makes according to example 1 2 and 4 g of PVP were dissolved in 77 g of DMF, then 18 g of PVDF was added, stirred at a certain temperature to dissolve it; and heated at 70 °C for defoaming. Spread a certain amount of casting solution on the non-woven fabric with a scraper, and form a film by phase inversion method. The prepared membrane was placed in tap water for more than 24 h to completely remove the organic solvent in the membrane. The newly prepared antibacterial film was used to measure its antibacterial performance against Escherichia coli and Pseudomonas aeruginosa. The results showed that the film had good antibacterial performance against both bacteria, and the antibacterial rate was 99%. At ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Protein adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com