Preparation method of fish gelatin high-molecular material

A polymer material and gelatin technology, which is applied in the field of preparation of fish gelatin polymer materials, can solve the problems of not paying attention to preventing the denaturation and degradation of fish collagen, poor performance of fish gelatin products, cumbersome processing process, etc. The effect of denaturation, short extraction time and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

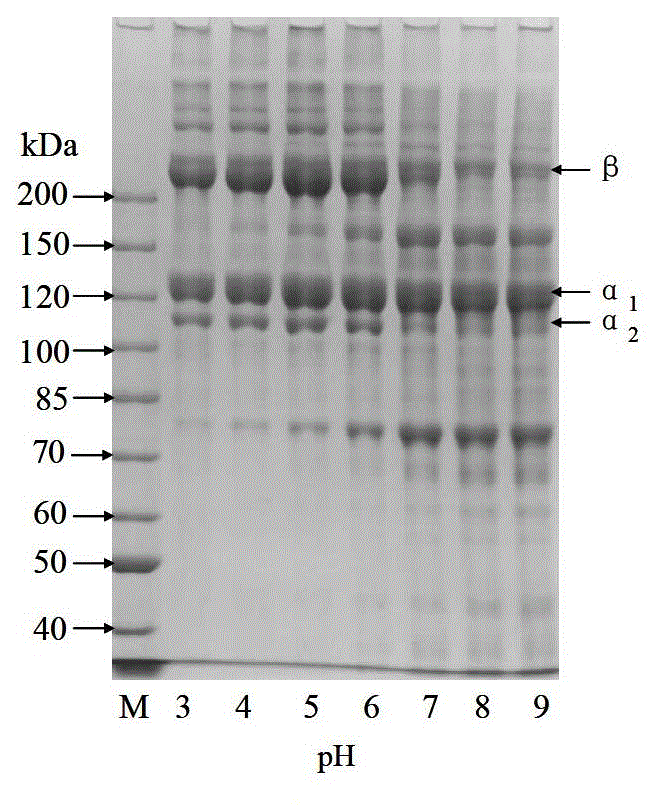

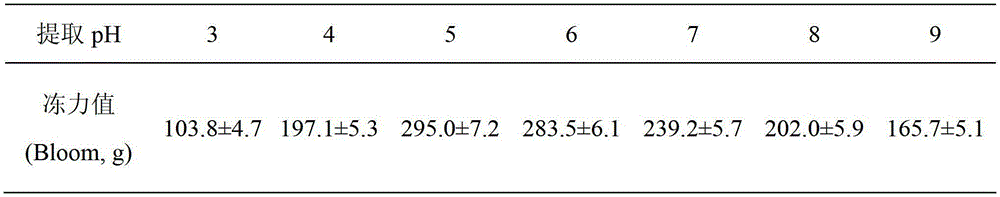

[0025] Add 5 L of 0.1% NaOH solution containing 0.2% sodium dodecyl sulfate (SDS) and 0.5% sodium percarbonate to 1 kg of tilapia fish scales, soak for 24 hours at 4°C, rinse with tap water, and drain. Add 1L of pure water, use citric acid or sodium hydroxide to adjust the pH of the fish scale aqueous solution to a certain value, then rapidly raise the temperature to 60°C, heat and keep warm for extraction for 1 hour, filter with filter paper, freeze-dry after cooling and solidifying, and obtain tilapia fish scales gelatin. The gelatin components of tilapia fish scales were determined by SDS-PAGE ( figure 1 ), the gel formation of gelatin can be measured by BLOOM (Table 1).

[0026] Table 1 Effect of extraction pH on the gel freezing force of tilapia scale gelatin

[0027]

Embodiment 2

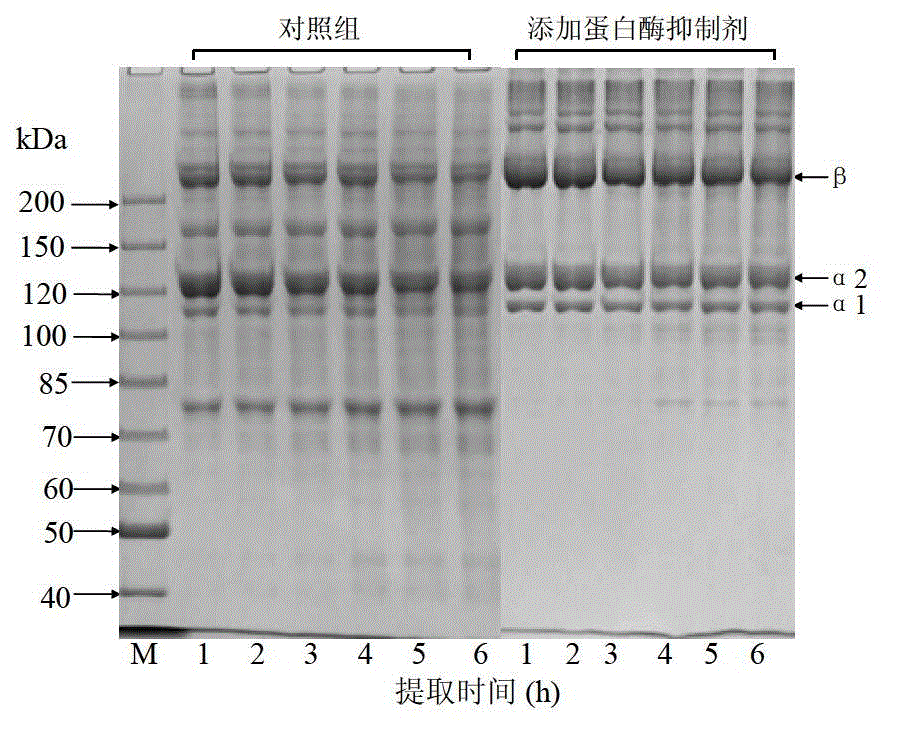

[0029] Add 5 L of 0.1% NaOH solution containing 0.2% SDS and 0.5% sodium percarbonate to 1 kg of tilapia fish scales, soak at 4°C for 24 hours, rinse with tap water and drain, then add 1 L of pure water to achieve a total weight of About 2kg, add 60mg of soybean extract (the specific activity of the inhibitor is 10000U / mg), adjust the pH of the solution to 9 with sodium hydroxide, then rapidly raise the temperature to 60°C, heat and keep it for extraction for a certain period of time, filter with filter paper, cool and solidify Then freeze-dry to obtain tilapia scale gelatin. At the same time, gelatin prepared without adding soybean extract was used as a control group. The results of SDS-PAGE determination of gelatin components are as follows figure 2 shown.

Embodiment 3

[0031] Add 10L of 0.4% NaOH solution containing 0.5% alkylphenol polyoxyethylene ether and 1.0% sodium hypochlorite to 1kg of cod skin, soak at 4°C for 12 hours, rinse with tap water, drain, and add 0.5L of pure When the total weight of water reaches about 2kg, add 100mg of soybean extract (the specific activity of the inhibitor is 10000U / mg) and 4g of trehalose, adjust the pH of the fish skin aqueous solution to 5 with adipic acid, and heat up to 70°C quickly after crushing. Heat and keep it warm for 1 hour, filter the obtained gelatin solution with a filter cloth, and after cooling and solidifying, cut into thin strips and blow dry at 15° C. to obtain cod skin gelatin. Table 2 shows the test results of the obtained gelatin gel properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com