Engineering bacteria for producing 1,3-propylene glycol and method for constructing same

A construction method and technology of engineering bacteria, applied in the field of engineering bacteria producing 1,3-propanediol and its construction, can solve problems such as unknown impact, achieve the effects of reducing toxic effects, reducing production costs, and reducing types of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

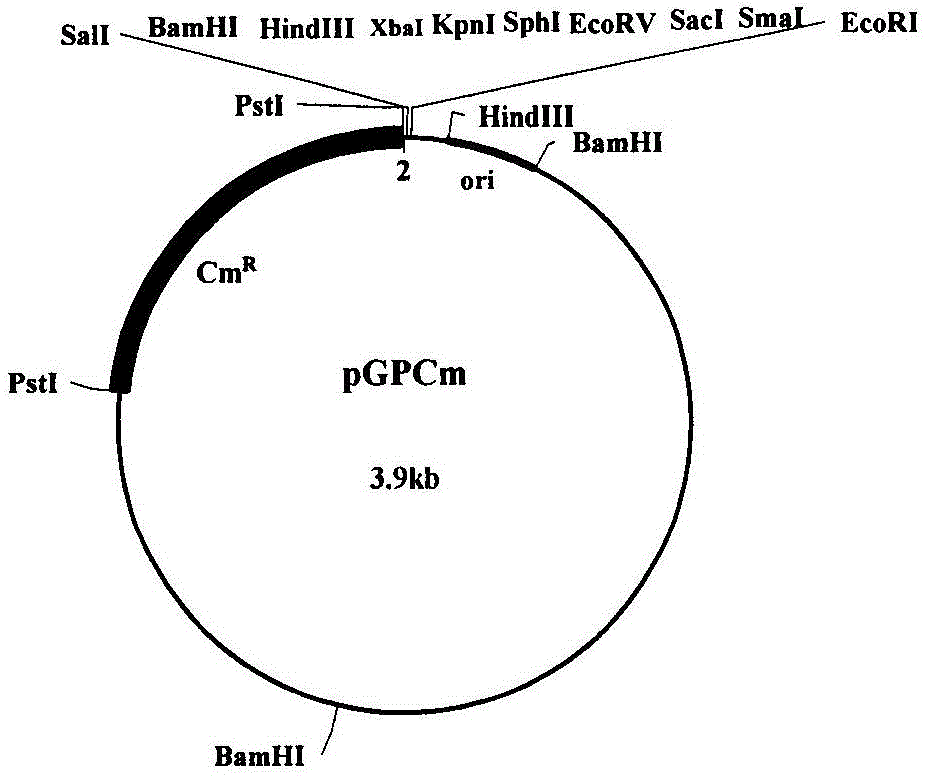

[0025] Example 1: Construction of a Klebsiella pneumoniae mutant strain in which the phosphotransacetylase gene, a key gene in the acetic acid metabolic pathway, is inactivated.

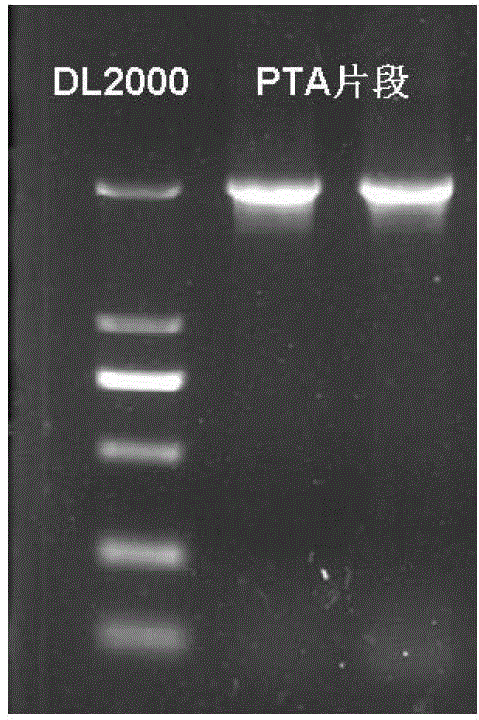

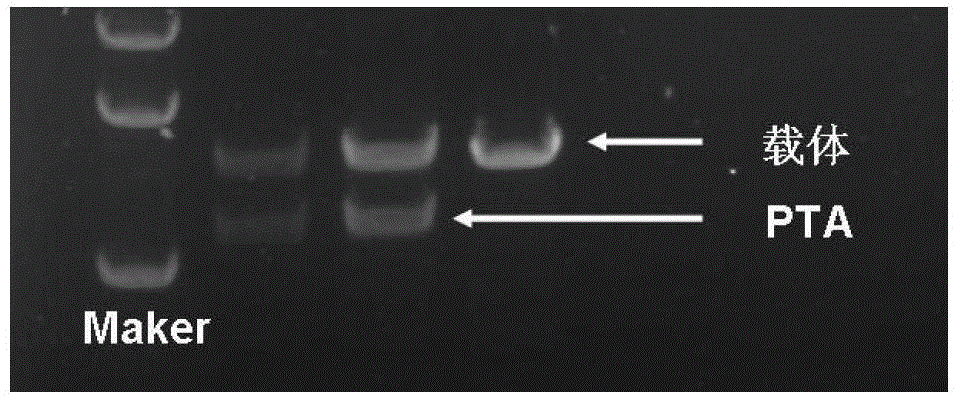

[0026] (1), cloning of phosphotransacetylase gene PTA partial sequence

[0027] Primers were designed according to the complete DNA sequence of the phosphotransacetylase gene PTA (GenBank number: YP_002920553.1), and its partial homologous sequence was amplified by PCR. The primer sequences were as follows: upstream primer PTA-F: TACCCGGGTACCAGCGTAGGTCTGACCAGCGTC and downstream primer PAT-R: GACCCGGGTTACTTCTGCTGCTGAGCCGATTG . Using wild-type Klebsiella pneumoniae (preserved in China Center for Type Culture Collection, deposit number: CCTCC M 2011075) genomic DNA as a template, under the guidance of primers PTA-F and PAT-R, PCR amplified phosphotransfer For the partial sequence of the acetylase gene PTA, the PCR amplification conditions are as follows: first 95°C for 3 minutes; then 94°C for 1 minute...

Embodiment 2

[0032] Example 2: Detection of the activity of the Klebsiella pneumoniae mutant strain in which the phosphotransacetylase gene was inactivated.

[0033] The Klebsiella pneumoniae mutant strain in which the phosphotransacetylase gene was inactivated in Example 1 is detected for the activity of phosphotransacetylase, and the wild-type Klebsiella pneumoniae is used as a control. The specific method includes the following steps:

[0034] (1) Inoculate the Klebsiella pneumoniae mutant strain in which the phosphotransacetylase gene is inactivated into 100 mL of culture medium (every liter of water contains 10 g of glycerol, 10 g of tryptone, 5 g of yeast powder, 5 g of NaCl, pH 7.0, 120° C. Sterilize for 20 minutes), shake and culture at 37°C for 6-12 hours, and collect bacteria by sampling and centrifuging every 2 hours;

[0035] (2) Suspend and wash the bacteria twice with 100mL phosphate buffer (0.1M, pH7.5);

[0036] (3) Suspend the bacteria with 2.5mL phosphate buffer (0.1M, p...

Embodiment 3

[0040] Example 3: Fermentative production of 1,3-propanediol by Klebsiella pneumoniae mutant strain with inactivated phosphotransacetylase gene

[0041] (1) culture medium

[0042] LB medium (g·L -1 ): yeast powder 5, peptone 10, NaCl10, agar 10, adjusted to pH 7.0, for short-term preservation and activation of Klebsiella species. The composition of seeds and fermentation medium is shown in Table 1:

[0043] Table 1: Medium Composition

[0044]

[0045] (2) Training method

[0046] (i) Seed activation: the Klebsiella pneumoniae mutant strain in which the phosphotransacetylase gene in Example 1 preserved from the glycerol tube was inoculated to the LB medium slant for activation, and the temperature was cultivated at 37° C. for 12 hours to activate the seeds .

[0047] (ii) Seed culture: 250mL triangular flask sealed with 9 layers of gauze, filled with 100mL of seed culture medium, connected to the slant lawn (activated seeds of step i), and carried out aerobic seed cul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com