Method for enhancing electrochemical performance of TiO2 electrode

An electrochemical and anodic oxidation technology, applied in the field of electrochemistry, can solve the problems of carrier recombination heat and electrochemical instability, achieve electrochemical performance, photoelectric catalytic performance and conductivity, and the processing method is simple and easy , the effect of solving energy problems and environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

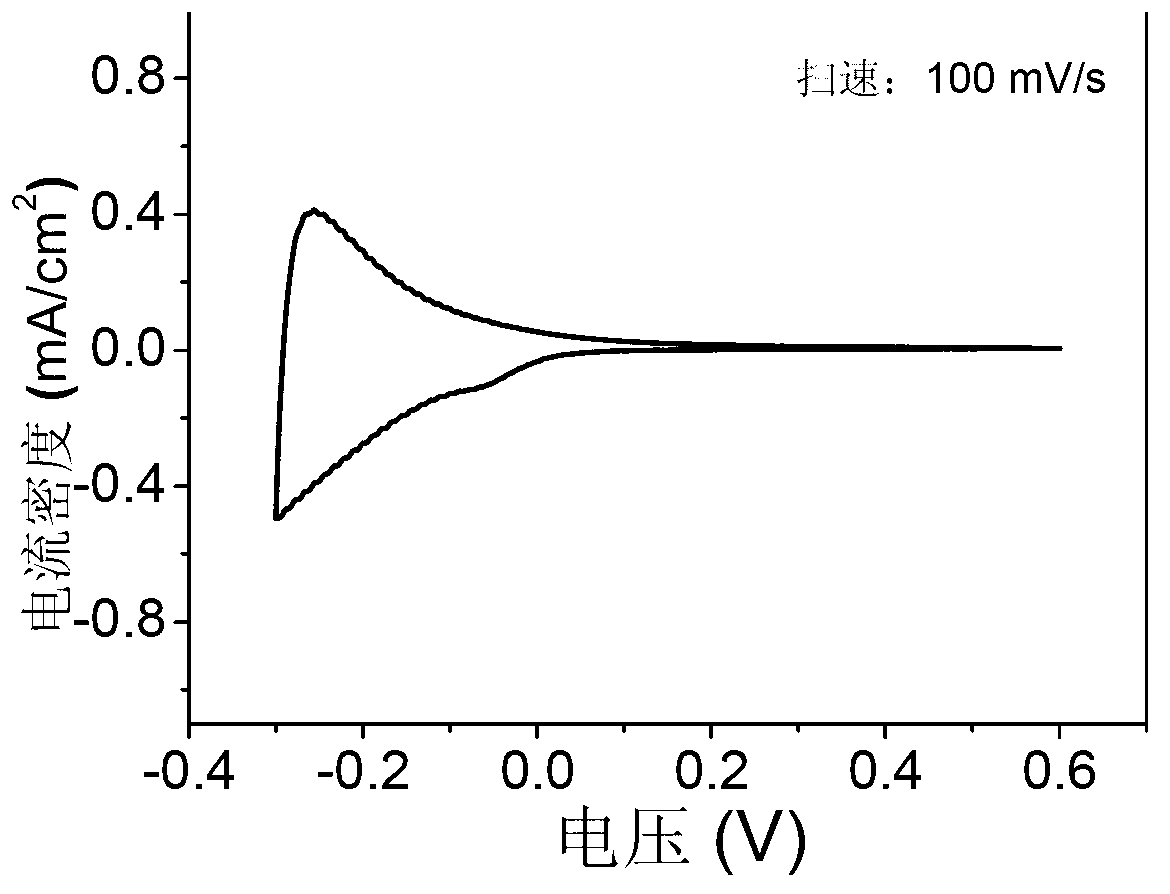

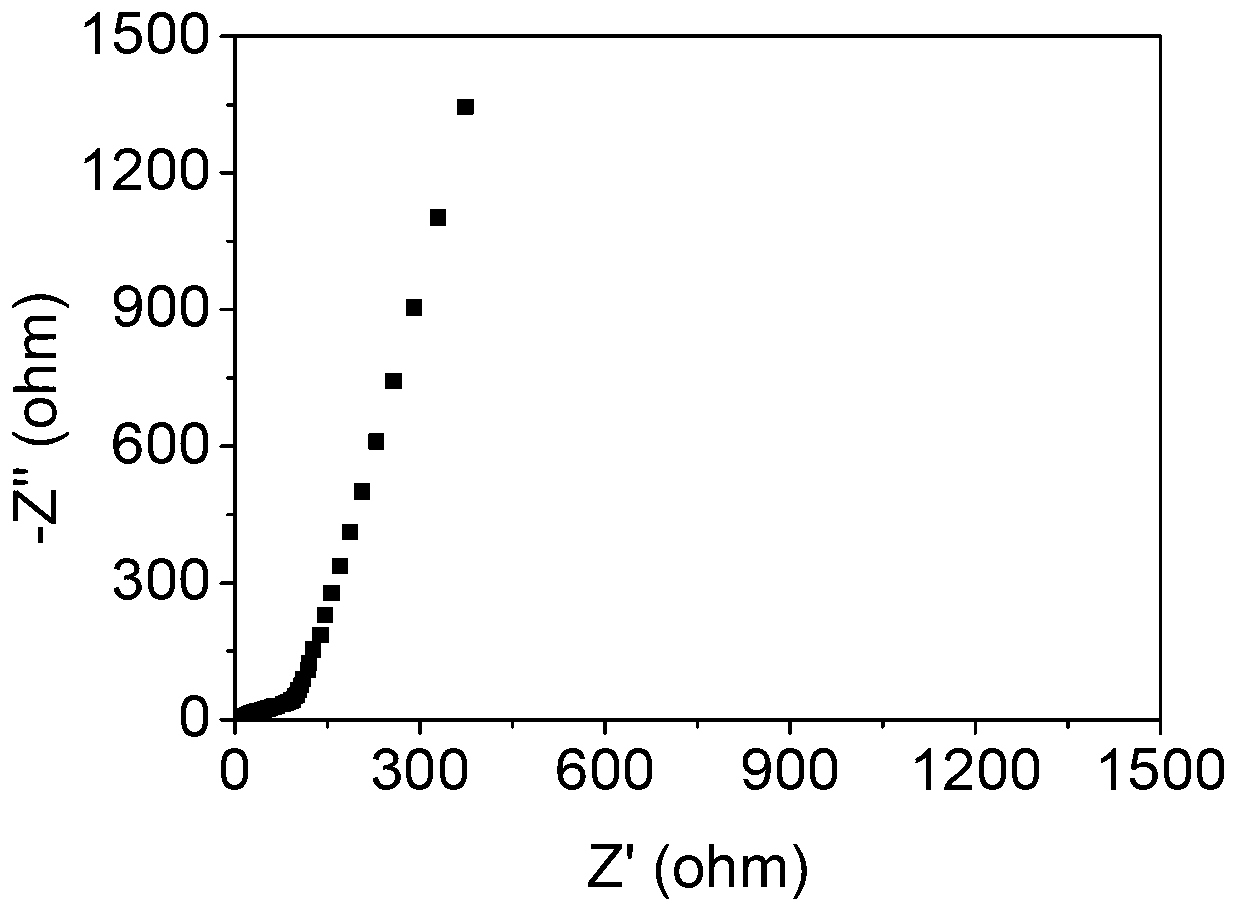

[0018] Preparation of TiO by Constant Pressure Oxidation 2 Electrode: Anodic oxidation is carried out in a two-electrode system with titanium foil as the working electrode and carbon rod as the counter electrode. The electrolyte is 0.5 wt % NH 4 F and 2 vol % H 2 O solution in ethylene glycol. First, put the titanium foil in the air at 450 ° C annealed for 20 min to eliminate structural stress, and then ultrasonically cleaned the titanium foil with acetone, ethanol, and water for 10 min. An anodic oxidation was carried out at a constant voltage of 60 V for 2 h, then the oxide film was removed by ultrasonication for 30 min, and the pitted titanium foil was cleaned with acetone, ethanol and water in sequence. Then carry out the second anodic oxidation, the oxidation conditions are the same as the first oxidation, and take out the TiO after the oxidation is completed. 2 The electrodes were rinsed with deionized water and dried. The prepared amorphous TiO 2 The electrode is ...

Embodiment 2

[0021] Preparation of TiO by Hydrothermal Method 2 Electrode: Add isopropyl titanate and isopropanol to acetic acid with pH=2 according to the volume ratio of 1:1 at room temperature, mix and stir, and then ° Heating in a C oil bath for about 1 h and stirring vigorously, then the solution was transferred to an autoclave, sealed at 250 ° Place under C for 12h. Finally, ultrasonically disperse the colloidal solution at 120 ° C Heated for a certain period of time to obtain a milky white colloid, which was applied to the cleaned conductive glass with a coating area of 1.2 cm 2 ,drying. The reverse voltage application process is the same as that in Embodiment 1. The test results show that the hydrothermal method to prepare TiO 2 The specific capacitance of the electrode is 63μF / cm 2 ; Treated TiO 2 Electrode specific capacitance reaches 1.06 mF / cm 2 . Hydrothermal preparation of TiO under UV at a wavelength of 365 nm and sunlight with an AM of 1.5 G 2 The photocurrents ...

Embodiment 3

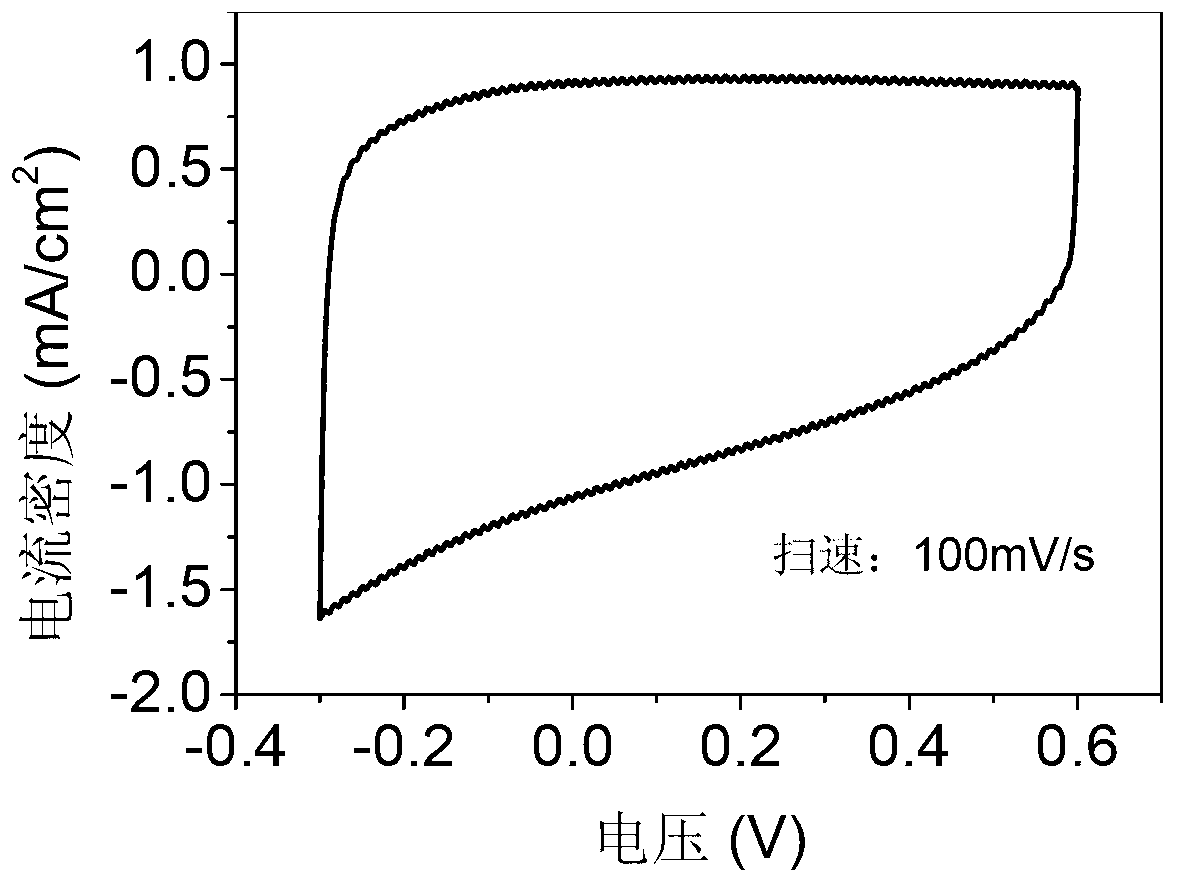

[0023] Preparation of TiO by template method 2 Electrode: The template is porous alumina with an aluminum substrate (remove the barrier layer, the pore size is 60 nm, the thickness is 20 microns, and the area is 1.2 cm 2 ), using 0.1 M (NH 4 ) 2 TiF 6 for the precursor. Immerse the porous alumina with aluminum substrate in the precursor solution, take it out after reacting for 1 h, rinse it with deionized water, and dry it. The reverse voltage application process is the same as that in Embodiment 1. The test results showed that the treated TiO 2 Electrode specific capacitance is 5.89 mF / cm 2 ; Under UV with a wavelength of 365 nm and sunlight with an AM of 1.5 G, the photocurrents can reach about 136 μA and 163 μA, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| photoelectricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com