Preparation method of zinc oxide/polyaniline composite photocatalyst

A technology of polyaniline and zinc oxide, which is applied in the field of preparation of zinc oxide/polyaniline composite photocatalyst, can solve the problems of visible light responsiveness and poor stability, and achieve the effect of improving emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of granular nano-zinc oxide and rod-shaped nano-zinc oxide by direct precipitation

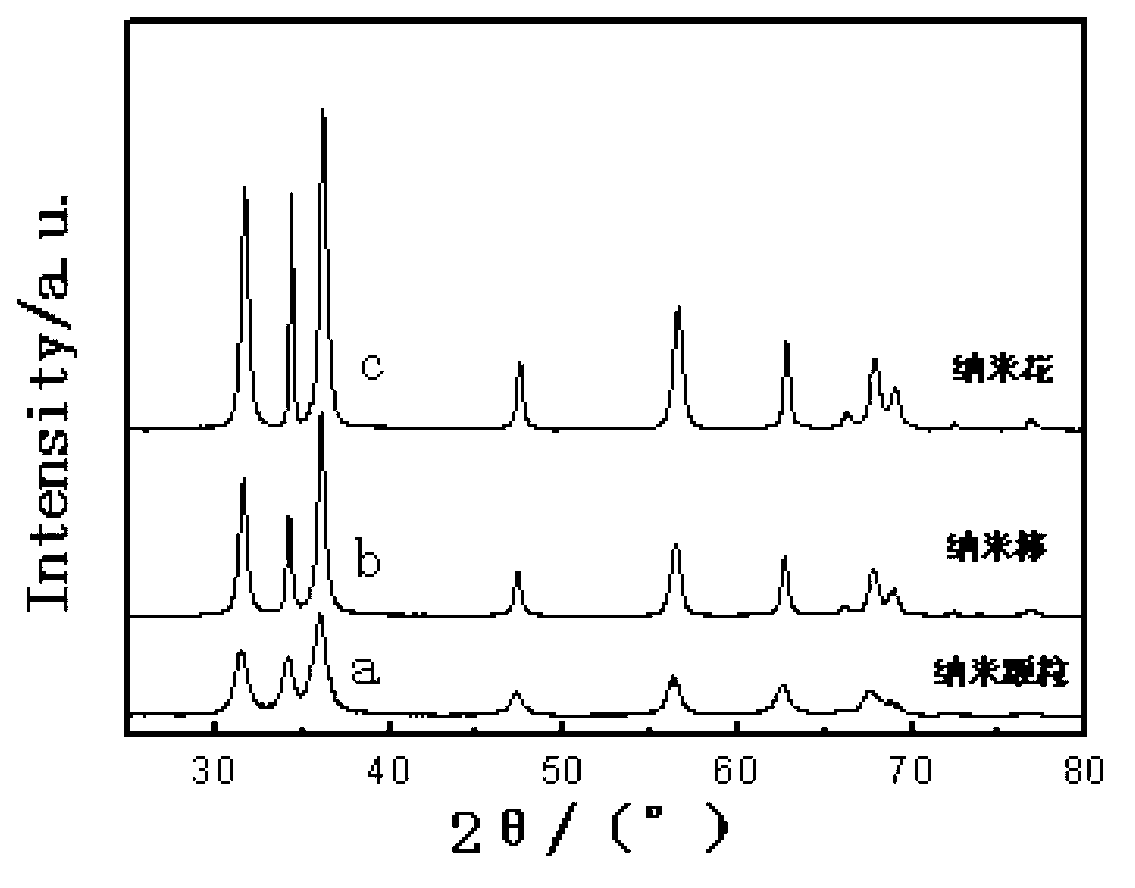

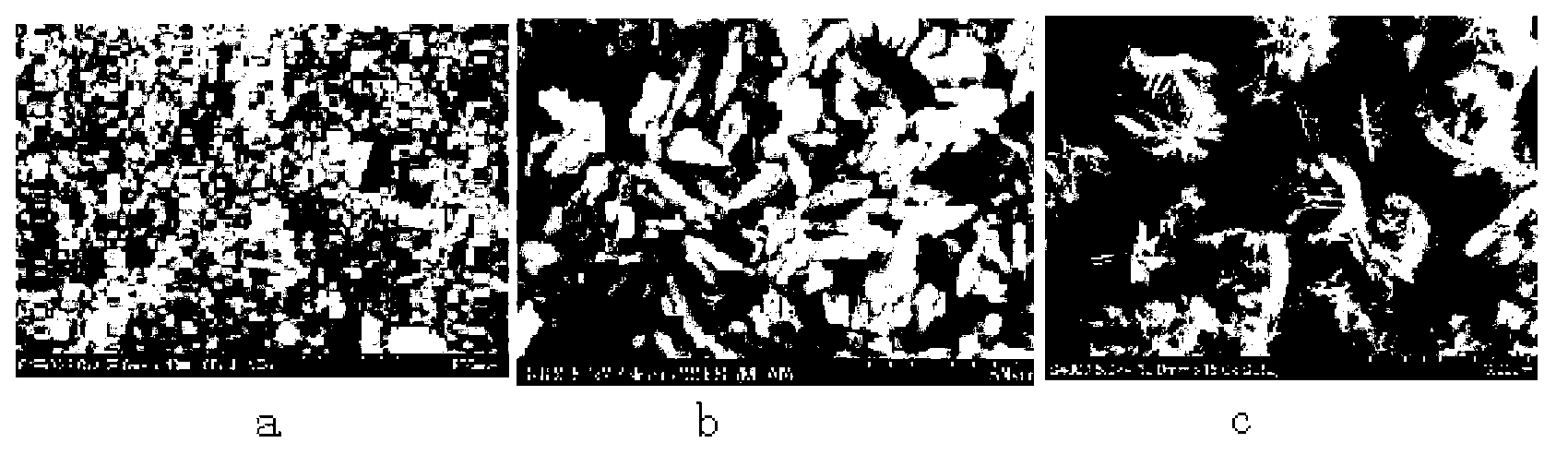

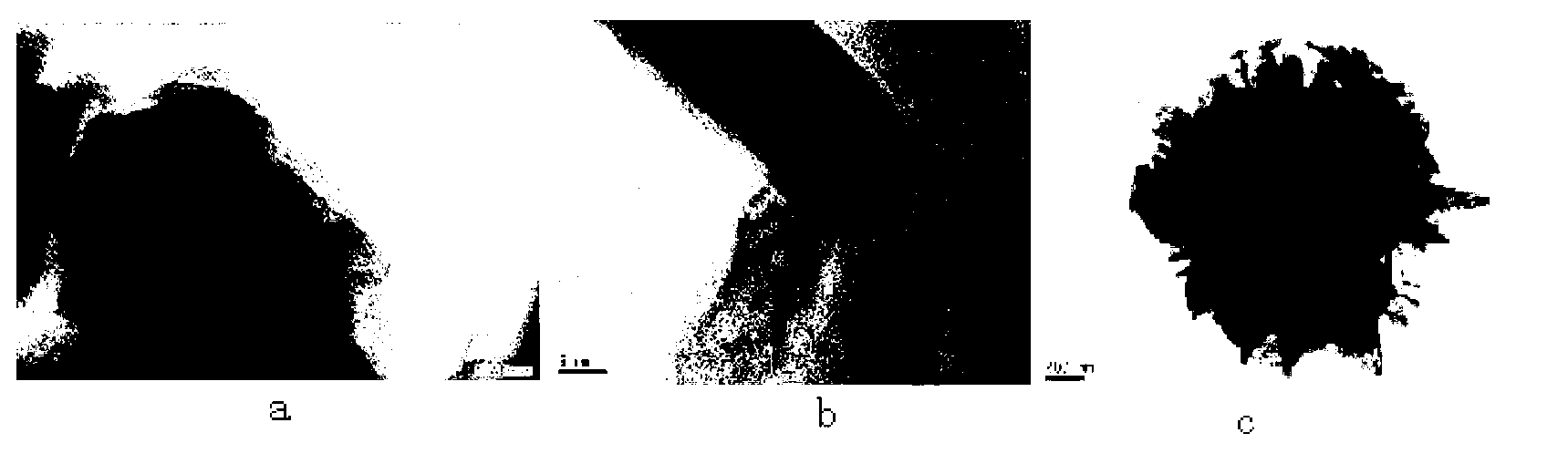

[0027] Weigh 0.02mol of zinc acetate and 0.04mol of sodium hydroxide and dissolve them in 100ml of ethanol respectively. Under magnetic stirring, quickly pour the dissolved NaOH ethanol solution into a round-bottomed flask containing a zinc acetate ethanol solution. After stirring at 25°C for 24 hours, centrifugation, washing with absolute ethanol and deionized water for several times in turn, and vacuum drying at room temperature to obtain a white powder, which was identified by X-ray powder diffraction as zinc oxide ( figure 1 a), identified by scanning electron microscopy as granular nano-ZnO with a particle size of about 30 nm ( figure 2 a).

[0028] Weigh 0.02mol of zinc acetate and 0.04mol of sodium hydroxide and dissolve them in 100ml of ethanol respectively. Under magnetic stirring, quickly pour the NaOH ethanol solution into the round-bottomed flask con...

Embodiment 2

[0029] Example 2: Preparation of spherical flower-shaped nano-ZnO with uniform morphology and size by hydrothermal method

[0030] Synthesis of spherical flower-shaped nano-zinc oxide controlled by hydrothermal method: Weigh 0.01mol of zinc acetate, dissolve it in 10ml of deionized water, add 20ml of pre-prepared 1M NaOH solution, and mix thoroughly. The obtained mixed solution was added into a polytetrafluoroethylene-lined high-pressure reaction kettle, and 8 ml of deionized water was added, and the hydrothermal reaction was carried out at 120 ° C for 12 hours, and naturally cooled to room temperature. It was washed three times with ionized water and absolute ethanol, and dried under vacuum to obtain a white powder. The product was identified as zinc oxide by X-ray powder diffraction (see figure 1 c), identified as spherical flower-like nano-ZnO by scanning electron microscopy, the thickness of the petal-like sheet is about 20 nm, and the diameter of the ball is about 2.0 μm ...

Embodiment 3

[0031] Example 3: Surface chemical modification of nano-zinc oxide

[0032] Add 0.5g of nano-zinc oxide to the round bottom flask, then add 0.1ml of silane coupling agent KH-42, 10ml of xylene, 0.5ml of H 2 O, stir evenly, reflux at 80°C for 3h, centrifuge, wash three times with deionized water and absolute ethanol in turn, and vacuum dry at 80°C for 12h to obtain nano-zinc oxide chemically modified by silane coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com