Recycling treatment method of water-submerged manure in breeding industry

A treatment method and resource-based technology, which is applied in the field of water-soaked manure in the aquaculture industry, can solve the problems of high transportation costs, high operating costs, and high difficulty in ammonia nitrogen treatment, achieving low operating costs and solving environmental protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

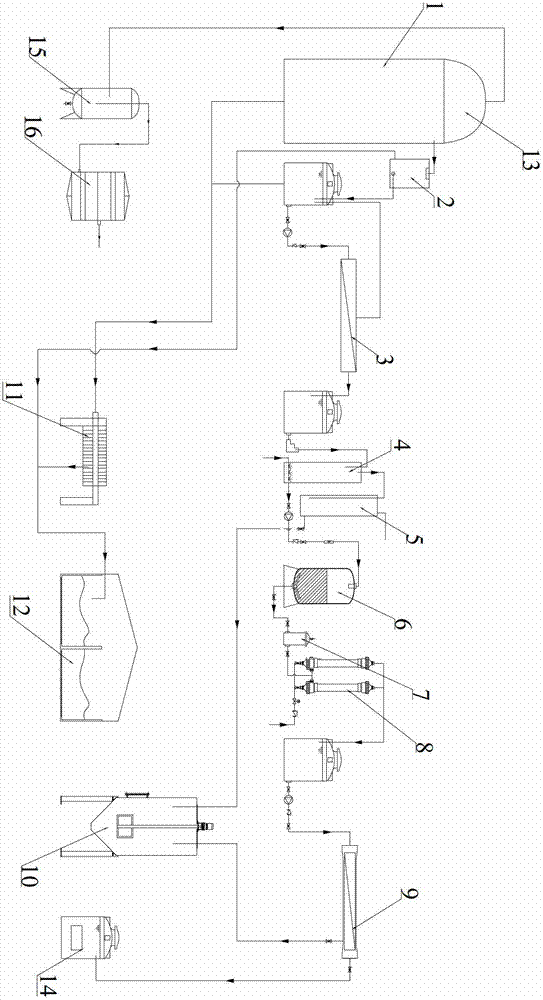

[0029] refer to figure 1 , the present invention provides a kind of aquaculture vesicle excrement resource treatment method, at comprising the following steps:

[0030] A. Discharge the feed liquid including feces and flushing water into biogas digester 1, and obtain biogas, biogas slurry and sludge after fermentation and biogas production in biogas digester 1. Biogas digester 1 adopts UASB (upflow anaerobic sludge bed) ) or IC (internal circulation anaerobic reactor) or CSTR (completely mixed anaerobic reactor) or HCF (high concentration plug flow) anaerobic fermentation unit, the biogas produced passes through the biogas storage membrane above the biogas digester 1 13 collection, the collected biogas is used as energy after being dehydrated and desulfurized by dehydration device 15 and desulfurization tower 16;

[0031] B. Pass the obtained biogas slurry through the solid-liquid separation device 2 for solid-liquid separation to obtain clear liquid and solid residue, and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com