Lithium-titanium complex oxide, and battery electrode and lithium ion secondary battery containing same

A composite oxide, battery technology, applied in battery electrodes, circuits, titanate and other directions, can solve the problem of battery performance degradation, and achieve the effect of inhibiting reaction, excellent stability over time, and improving stability over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

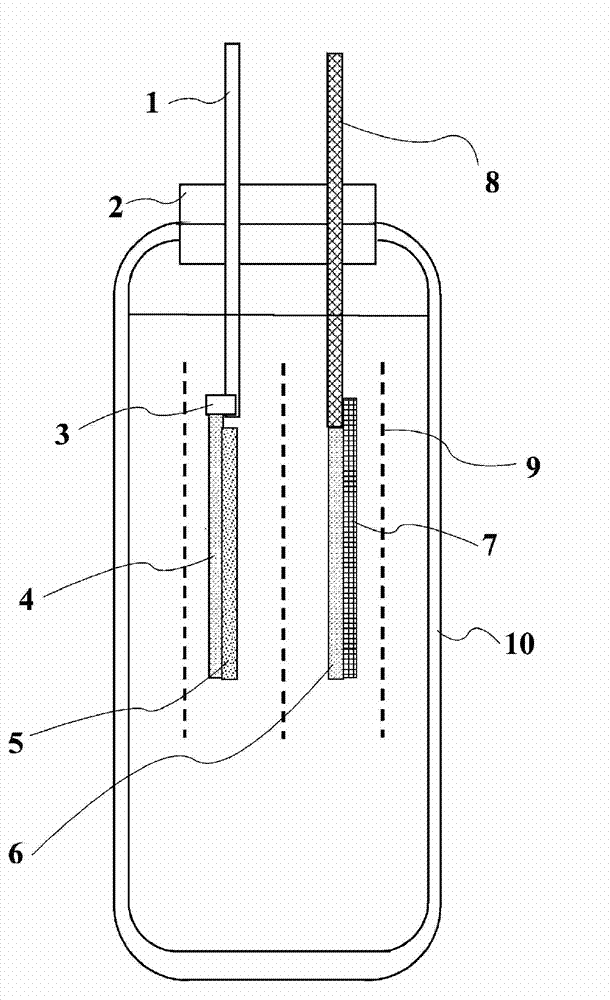

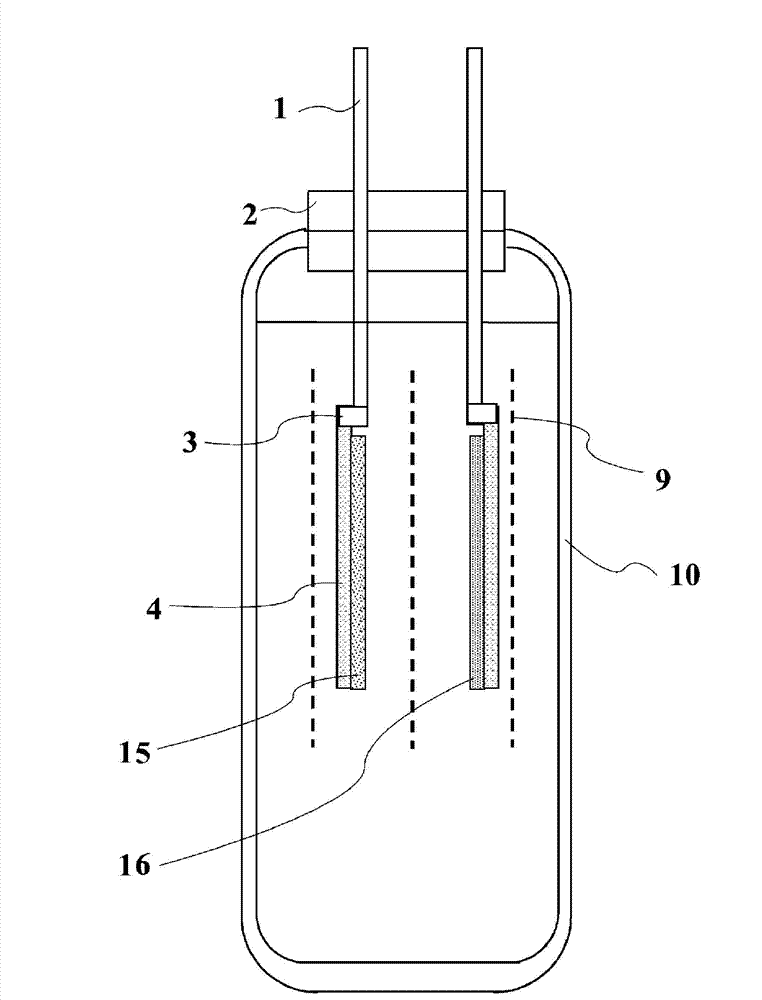

Image

Examples

Embodiment )

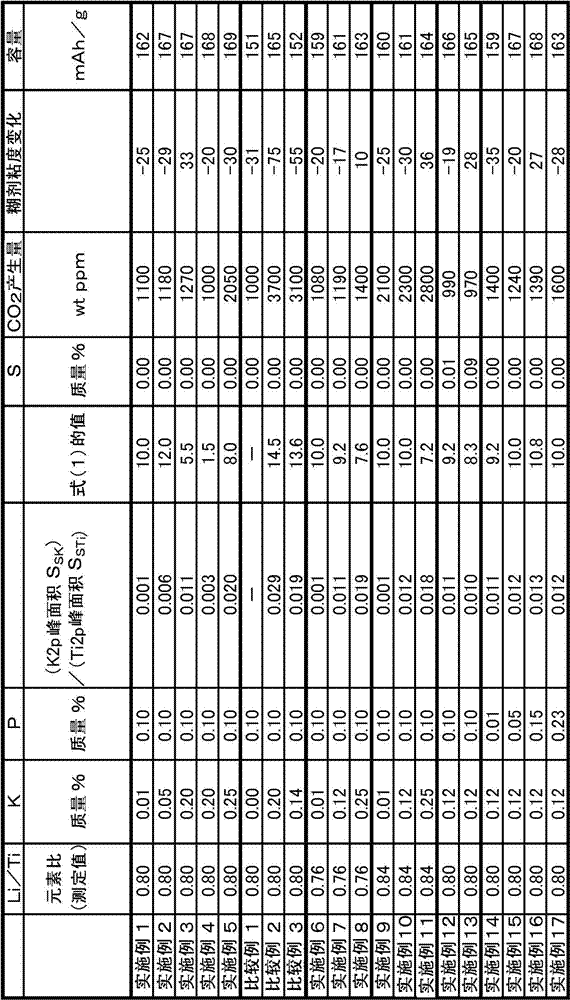

[0076] Next, the present invention will be described more specifically based on examples. However, the present invention is not limited to the aspects described in these Examples. First, analysis and evaluation methods of the samples obtained in the respective examples and comparative examples will be described.

[0077] (Elemental analysis)

[0078] Quantitative analysis of contained elements is carried out by atomic absorption spectrometry or ICP emission spectrometry after the sample of titanium-lithium composite oxide is subjected to pressurized acid decomposition. The ratios (% by mass) of potassium, phosphorus, and sulfur were calculated relative to the weight of 100% of the titanium-lithium composite oxide. For lithium, the value quantified by ICP emission spectroscopic analysis was used. For titanium, the Li / Ti molar ratio was calculated using a value obtained by subtracting the value of the intense heat loss up to 900° C. and the mass of all the elements quantifie...

Embodiment 1)

[0091] The feed Li / Ti atomic ratio was set to 0.805. The Li source is lithium carbonate (a high-purity commercially available reagent with a purity of 99%), and the titanium oxide is a high-purity product with a purity of 99.9% and a specific surface area of 10±1m 2 / g of titanium oxide. The pure water of the dispersion medium was added so that the solid content concentration was 52% by mass, potassium hydroxide was added as a potassium source, and ammonium dihydrogen phosphate was added as a phosphorus source to obtain a slurry.

[0092] The resulting slurry was mixed with a bead mill. Then, the dispersion medium was removed with a spray dryer, and heat-treated at 820° C. for 3 hours in the air. Then, use pure water and a bead mill for crushing, and dry the filter cake after filtration and punching. After dry crushing, it will not contain CO 2 (less than 1ppm) of 20%O 2 -80%N 2 In an atmosphere of mixed gas (dew point -70°C), heat-treat at 500°C for 1 hour, and cool to...

Embodiment 2)

[0095] The feed Li / Ti atomic ratio was set to 0.805. The Li source is lithium carbonate (a high-purity commercially available reagent with a purity of 99%), and the titanium oxide is a high-purity product with a purity of 99.9% and a specific surface area of 10±1m 2 / g of titanium oxide. Potassium hydroxide was added as a K source, and ammonium dihydrogen phosphate was added as a phosphorus source. currently using The balls were dry-mixed with a planetary ball mill for 2 hours, and heat-treated at 820° C. for 3 hours in the atmosphere. Then, by using pure water and a bead mill for pulverization, the filter cake after filtration and punching is dried for dry crushing so as not to contain CO 2 (less than 1ppm) of 20%O 2 -80%N 2 Atmosphere of mixed gas (dew point -70°C), heat treatment at 400°C for 1 hour, and cool to room temperature without exposure to the atmosphere. The value calculated by the above formula (2) is 0.0010.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com