Anti-ageing yoghourt containing flavonoid compounds and production method for same

The technology of a flavonoid compound and a production method is applied in the field of fermented dairy product processing, and can solve the problems of inability to market, the appearance of yogurt products, the influence of the stability of the flavor system, and the influence of product quality, so as to improve production efficiency and expand anti-aging functionality. , the effect of reducing the risk of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

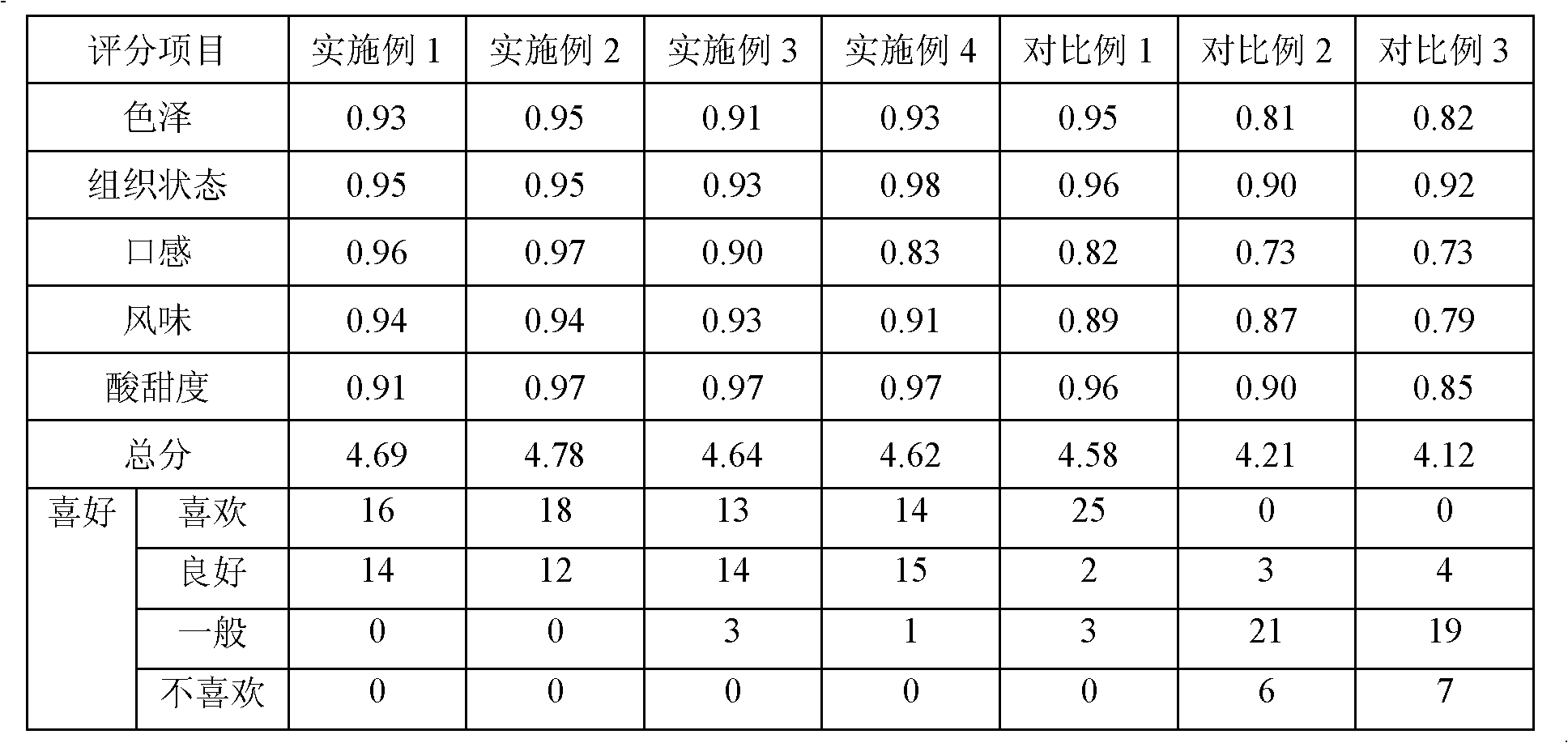

Embodiment 1

[0041] Embodiment 1 Stirred yoghurt rich in flavonoids and preparation method thereof

[0042] 1. Pretreatment of flavonoids:

[0043] The raw material of flavonoids used in this example is seabuckthorn flavonoids (hereinafter referred to as seabuckthorn flavone raw materials), purchased from Beijing Gaoyuan Shengguo Seabuckthorn Products Co., Ltd., mainly extracted from seabuckthorn fruits, in the form of dark brown powder, non-toxic and side effects, slightly bitter taste , the total flavonoid content in the raw material is about 50%.

[0044] Take 100g of the seabuckthorn flavonoid raw material, fully dissolve it in about 100ml of edible alcohol (purity about 90%); take 500g of β-cyclodextrin, and prepare it in a saturated aqueous solution at 60°C; dissolve the flavonoid compound with edible alcohol Add it into the saturated aqueous solution of β-cyclodextrin, keep stirring slowly (60-200rpm) at 60°C for 2 hours to obtain a white suspension, cool to room temperature and le...

Embodiment 2

[0054] Embodiment 2 is rich in the set type yoghurt of flavonoid compound and its preparation method

[0055] 1. Pretreatment of flavonoids:

[0056] The raw materials of flavonoids used in this example are the same as those in Example 1.

[0057] Take 100g of the seabuckthorn flavonoid raw material, fully dissolve it in about 100ml of edible alcohol (about 90% purity); take 400g of β-cyclodextrin, and prepare it in a saturated aqueous solution at 62°C; dissolve the flavonoids dissolved in edible alcohol The compound was added to the saturated aqueous solution of β-cyclodextrin, and the temperature was maintained at 62°C and stirred slowly for 2 hours to obtain a white suspension, which was cooled to room temperature and left to stand overnight, filtered to obtain a precipitate, and the obtained precipitate was dried at 45°C , to obtain the pretreated flavonoids.

[0058] The pretreated flavonoids are white powder without peculiar smell. After testing, the flavonoid compoun...

Embodiment 3

[0067] Embodiment 3 Stirred yoghurt rich in ginkgo flavonoids and its preparation method

[0068] 1. Pretreatment of flavonoids:

[0069] The raw material of flavonoids used in this example is commercially available ginkgo flavonoids (ginkgo biloba extract), which is a light yellow-brown flowable brown-yellow powder with a slight smell of ginkgo leaves and a bitter taste. Wherein the total flavone glycoside content: 24-26% (HPLC method), total terpene lactone content 8-10% (HPLC method), bilobalide ≥ 2.5%, ginkgolide A ≥ 1.4%, ginkgolide B ≥ 1.2% %, ginkgolide C ≥ 0.9%, ginkgolic acid ≤ 1-5ppm, heavy metal content ≤ 20ppm, AS ≤ 1PPM, loss on drying ≤ 3%, residue on ignition ≤ 1.5%, and solvent residue ≤ 1%.

[0070] Get 100g of the ginkgo flavone raw material, fully dissolve in about 80ml of edible alcohol (purity about 90%); get 500g beta-cyclodextrin, and mix it in a saturated aqueous solution at 62°C; Add it to the saturated aqueous solution of β-cyclodextrin, keep the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com